Intelligent tobacco leaf grading equipment

A tobacco leaf and grading technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of low efficiency of manual grading, laborious and laborious professionals, different judging grades, etc., and achieve intelligent grading and collection, and accurate test results. , the effect of high grading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

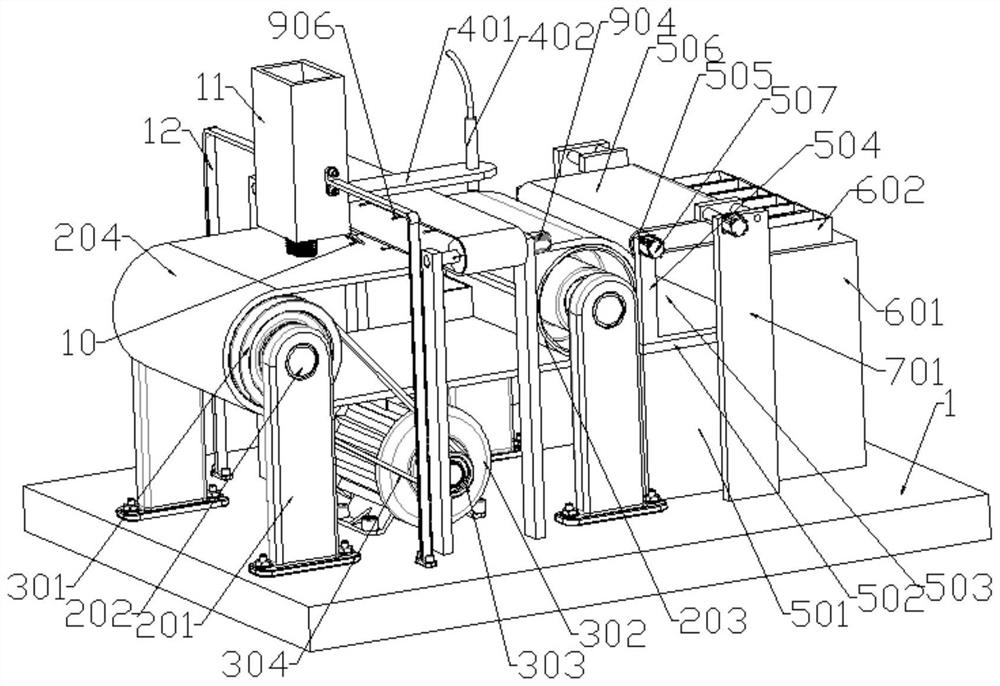

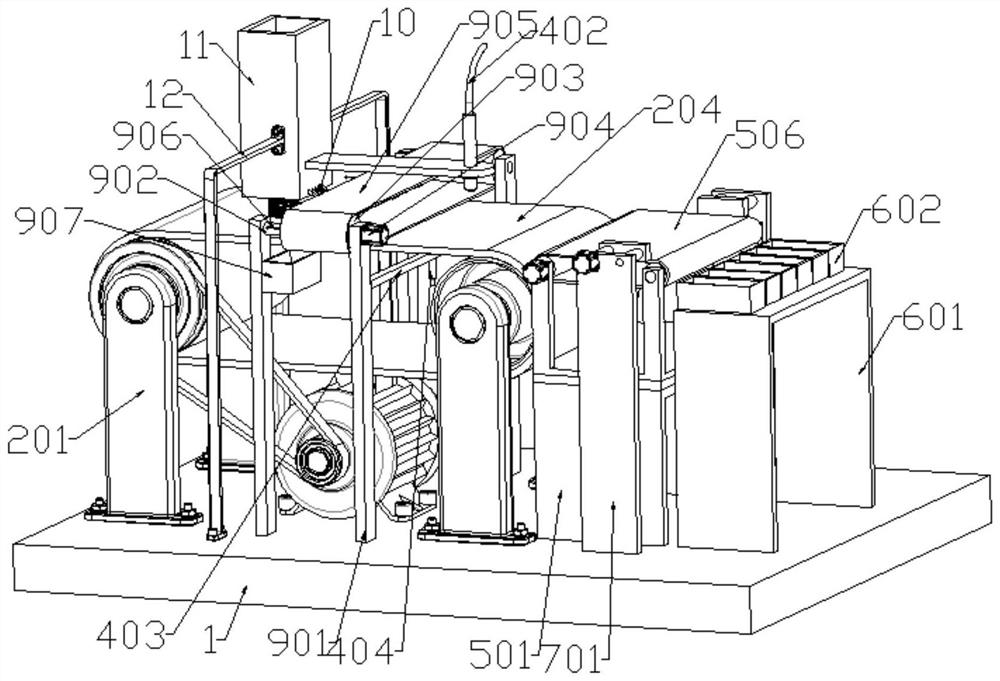

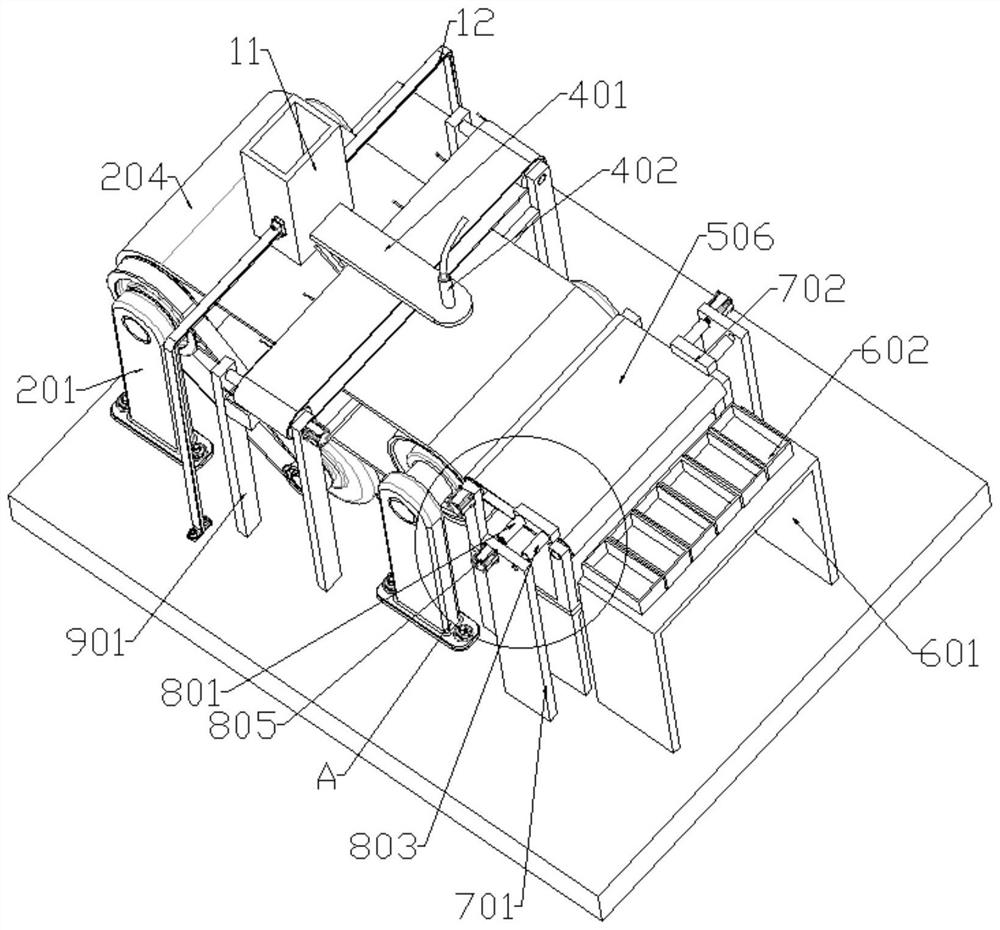

[0026] Such as Figure 1~4 As shown, the present invention provides an intelligent tobacco grading device. Tobacco leaf is an important economic crop with a very wide planting area in my country. Tobacco leaves need to be grouped and graded during the production process. The inventor conducted an in-depth investigation and research on the tobacco leaf grading process and found that: at present, all tobacco leaf grading uses manual grading. However, manual grading requires the use of a large number of professionals, and the training of professionals is laborious. At the same time, the manual grading efficiency is low. Moreover, manual grading is highly arbitrary, and different personnel determine different grades, which cannot solve the problem of fairness.

[0027] The above problems have not been reported publicly in the art, and the inventor has discovered the above problems and designed the technical solution.

[0028] Such as Figure 1-4 As shown, a tobacco leaf intelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com