Electronic cigarette ceramic core automatic detection equipment

An automatic detection and ceramic core technology, which is applied in sorting and other directions, can solve problems such as easy accumulation of residual materials, lack of discharge devices, ceramic core resistance size data and bottom surface cannot be guaranteed to be detected, so as to avoid accumulation of residual materials , Improve test efficiency and ensure the effect of loading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

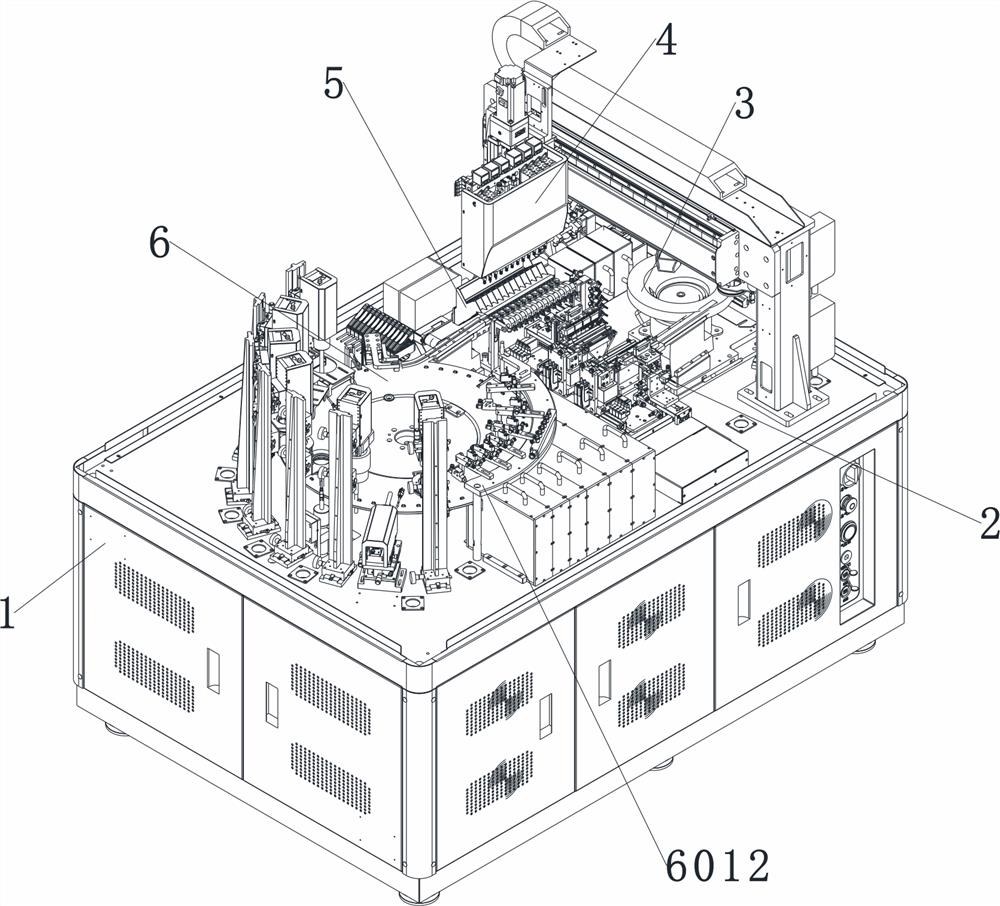

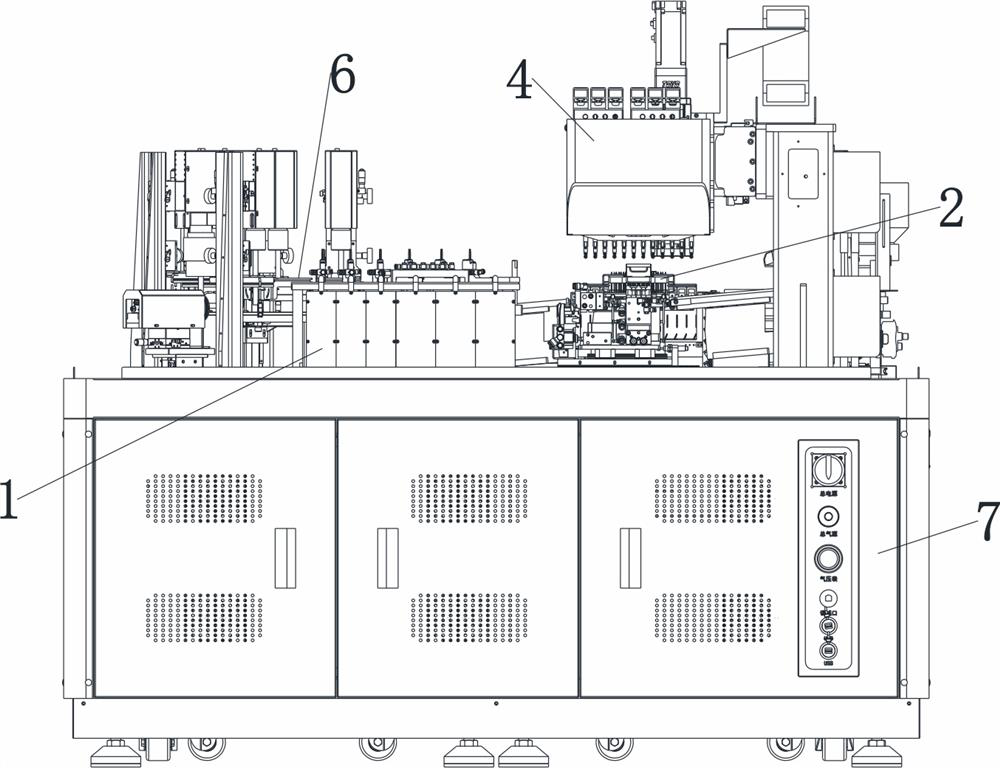

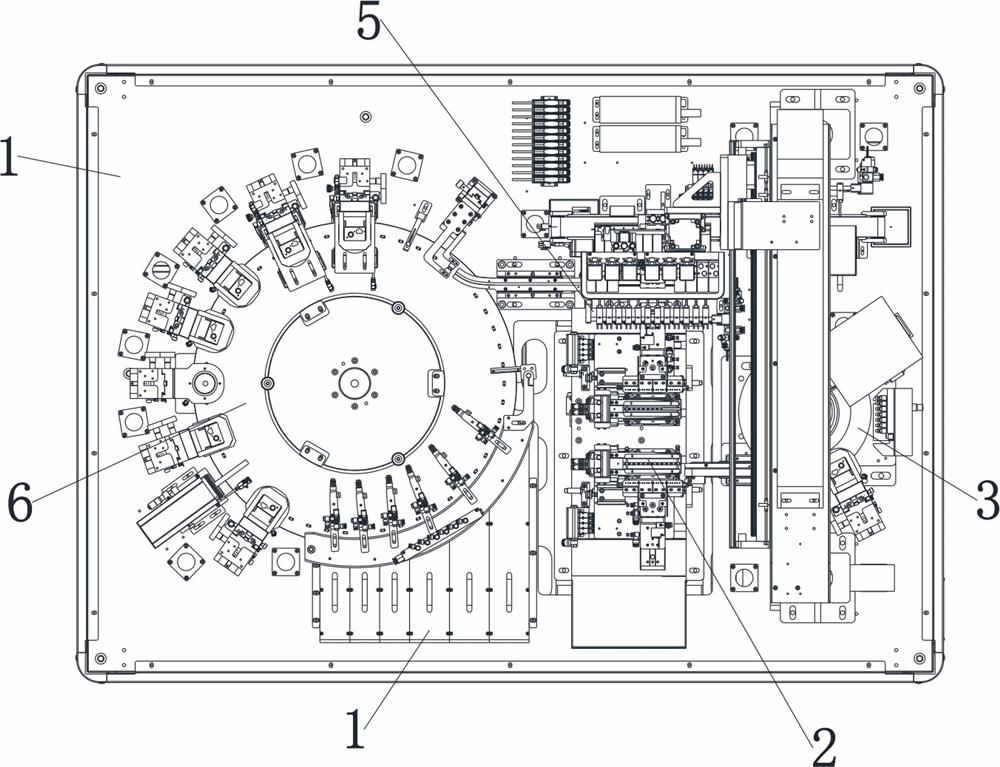

[0037] Such as Figure 1-Figure 11 As shown, an electronic cigarette ceramic core automatic detection equipment includes a workbench 1, an automatic feeding component 3 is arranged on the upper side of the workbench 1, and a product handling component 4 is arranged on the upper side of the automatic feeding component 3, and the automatic feeding One side of the component 3 is provided with a resistance value test component 2, one side of the resistance value test component 2 is provided with a resistance value defective product classification component 5, and the side of the resistance value test component 2 far away from the automatic feeding component 3 is provided with a resistance value qualified product visual inspection Component 6;

[0038] The resistance value test component 2 includes the No. 1 cylinder control module 201, the test group translation switching mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com