Self-compensating J-shaped wire clamp installer

An installer and self-compensation technology, which is applied in the direction of equipment for connecting/terminating cables, etc., can solve problems such as failure of parallel grooves, low efficiency of J-shaped clamps, and low clamping force of clamps, so as to improve safety and efficiency performance, improve the actual installation efficiency, and improve the effect of using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

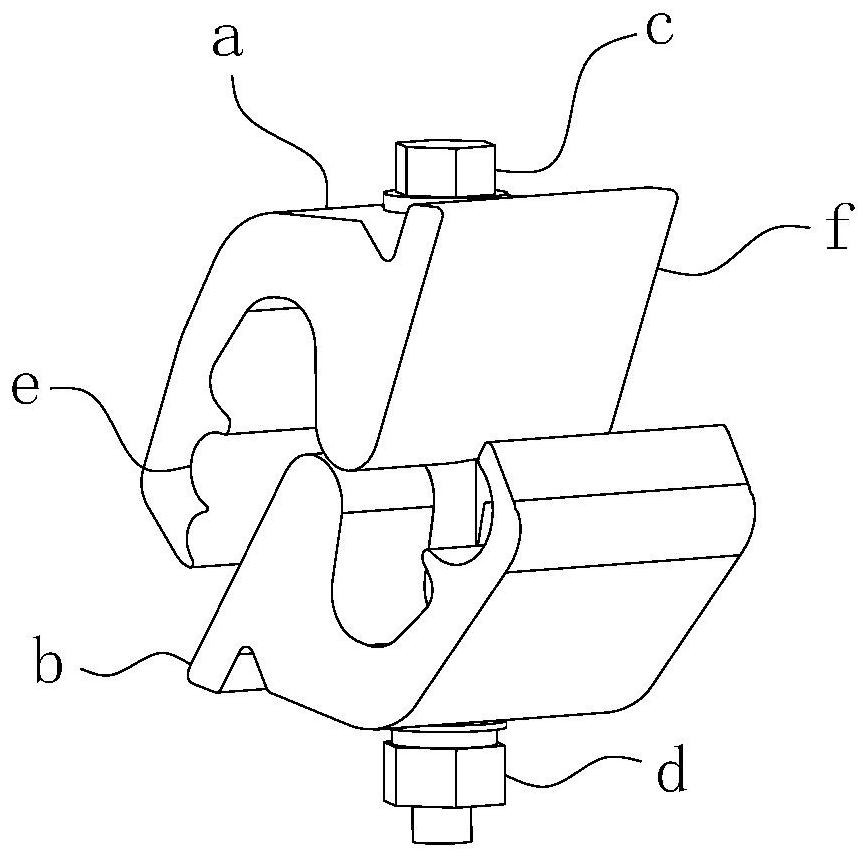

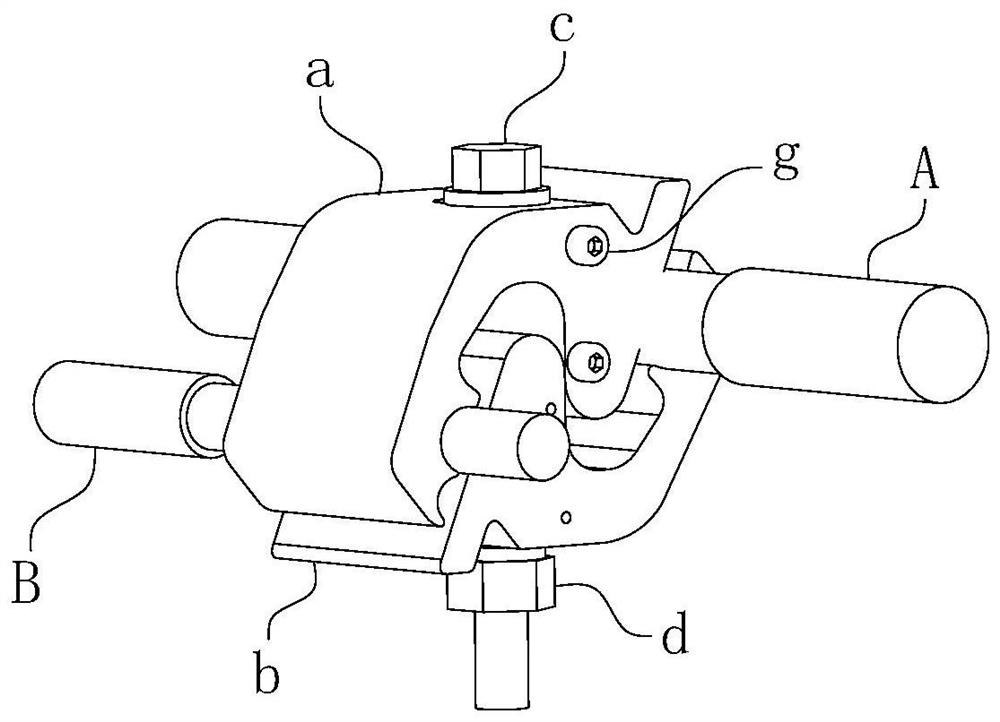

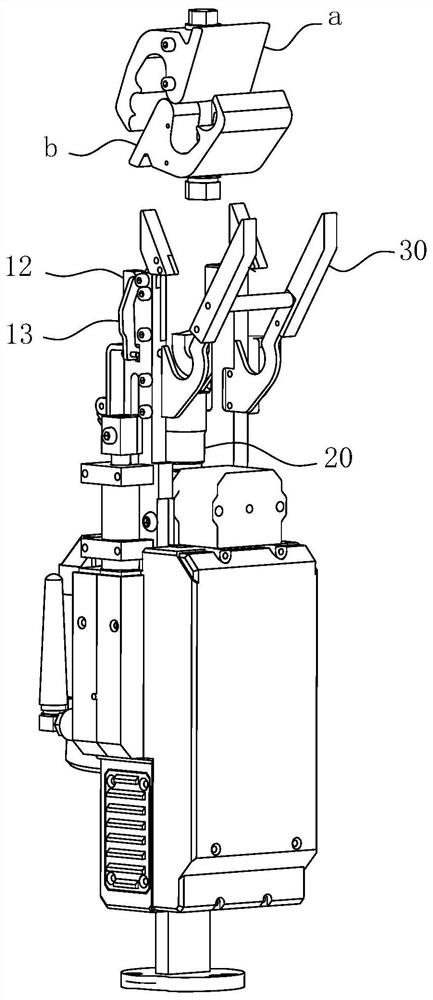

[0042] For ease of understanding, combined here Figure 1-14 , taking the installation and construction of the traditional J-shaped wire clamp as an example, the following is collectively referred to as the wire clamp, and the specific structure and working method of the present invention are further described as follows:

[0043] The present invention can be used in remote control equipment such as robots; during actual assembly, the present invention can be fixed on the mechanical arm. At this time, since the main line is fixed as a reference object, the present invention can be lifted by the mechanical arm to complete the relative main line. The upper top type clamp and ditch operation. The traditional line clip installation method is to hook from top to bottom relative to the main line. The present invention adopts a bottom-to-top jacking installation relative to the main line. There is no need to make a leaping action during work, so it can significantly reduce the comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com