Miniaturized high-reliability external modulation light source packaging structure and packaging method

A technology of packaging structure and external modulation, which is applied to the packaging structure and packaging field of miniaturized high-reliability externally modulated light sources, can solve the problems of low reliability of pin assembly, affecting the long-term reliability of solder joints, large volume and weight, etc. Reliable electrical signal transmission, small structure and high stability of optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

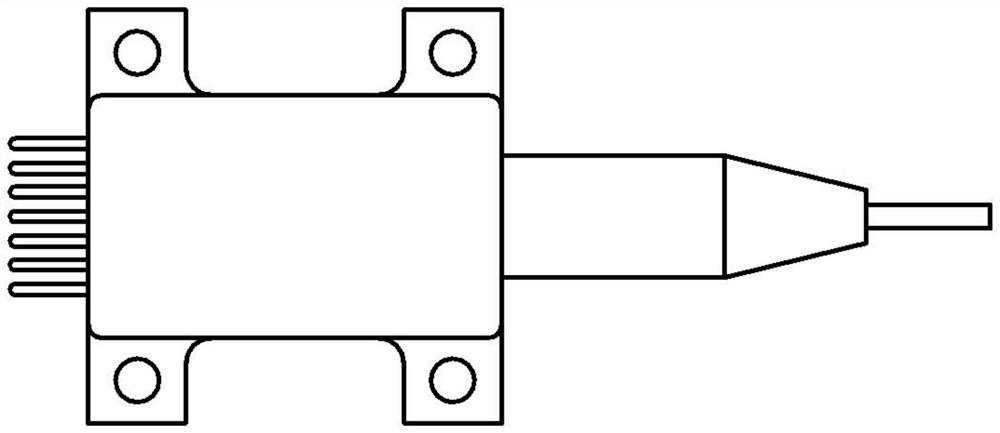

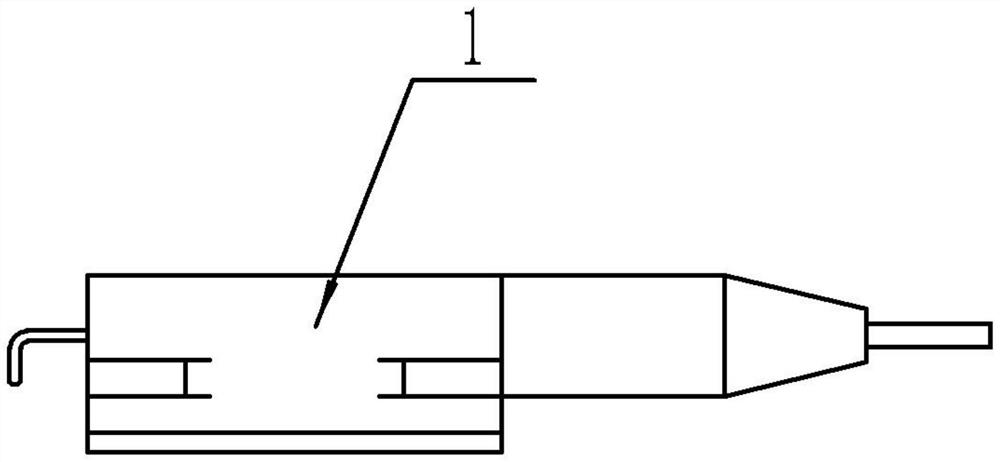

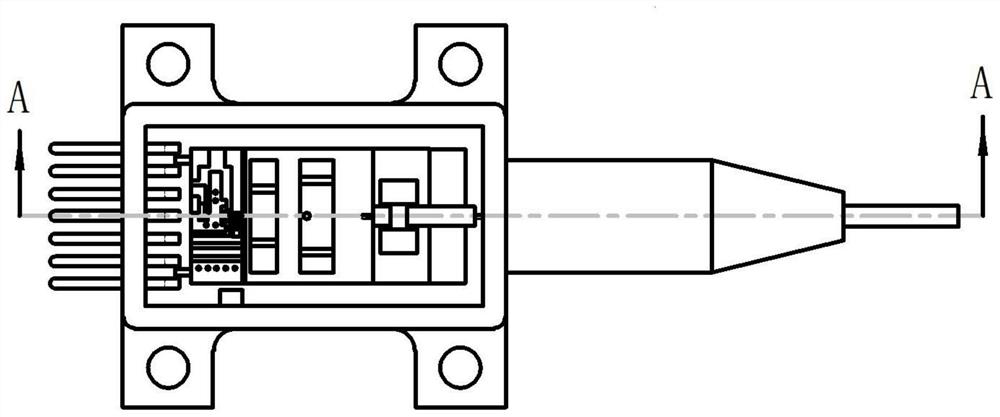

[0050] like Figure 1a , 1b , 1c, and 1d are schematic diagrams of the package structure of a miniaturized and highly reliable externally modulated light source proposed in this embodiment, as shown in Figure 2a , 2b Shown is a schematic installation diagram of a miniaturized and highly reliable externally modulated light source packaging structure proposed in this embodiment installed on the mounting base 6 and interconnected with the PCB 7 . This embodiment proposes a miniaturized and highly reliable externally modulated light source package structure, including a package shell 1, a ceramic circuit board 2, an optical coupling system 3, an optical base 4, and a thermoelectric cooler 5 (that is, a semiconductor cooler); the package The housing 1 includes a housing wall 11, close-packed glass terminals 12, and a bottom cooling plate 13; the optical coupling system 3 includes an aspheric lens 31, an isolation lens 32, and a metallized inclined optical fiber assembly 33 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com