Mixer

A technology of mixer and discharge port, which is applied in the field of coal slime water mixing and mixing, can solve problems such as coal sales troubles in coal preparation plants, adverse effects on the economy and reputation of coal preparation plants, and inability to meet the needs of buying houses, etc., to achieve convenient and fast assembly and disassembly , to avoid the effect of agglomeration and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For ease of understanding, the specific embodiments and operations of the present invention are further elaborated as follows in conjunction with the accompanying drawings:

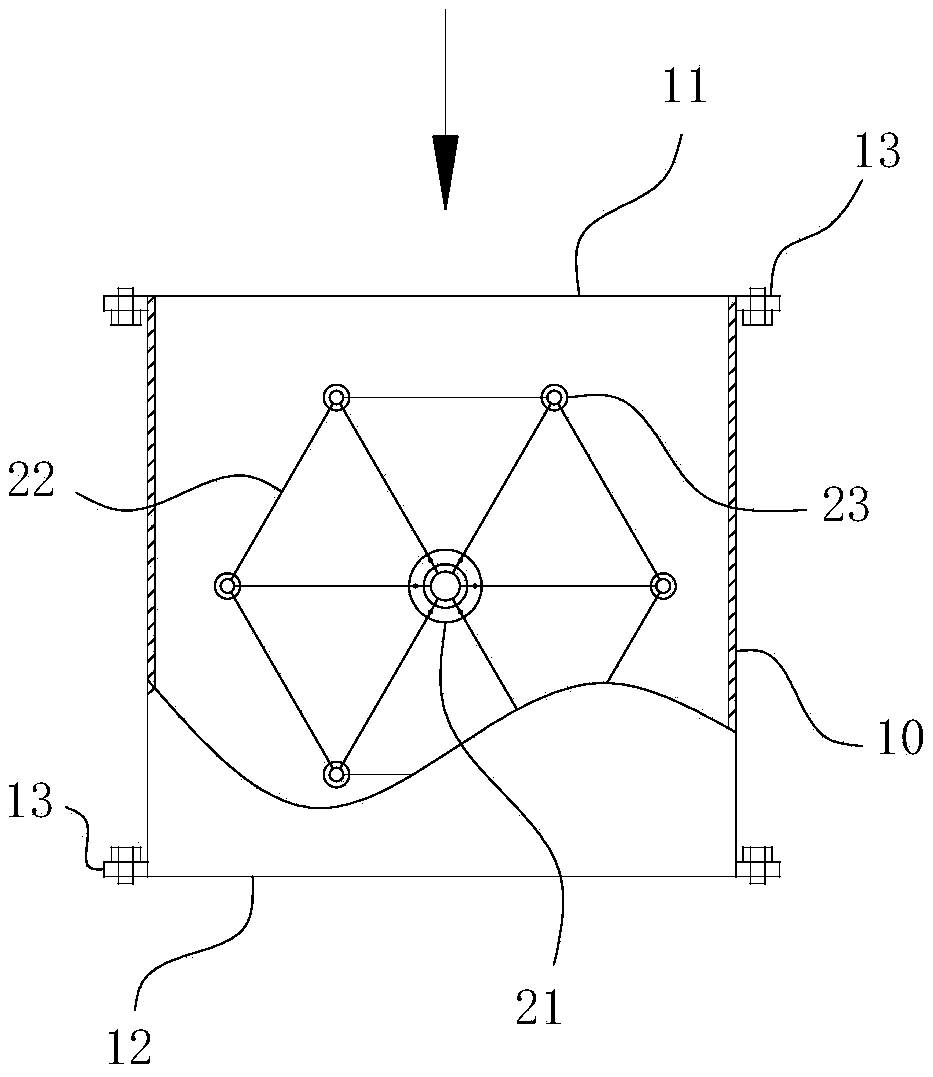

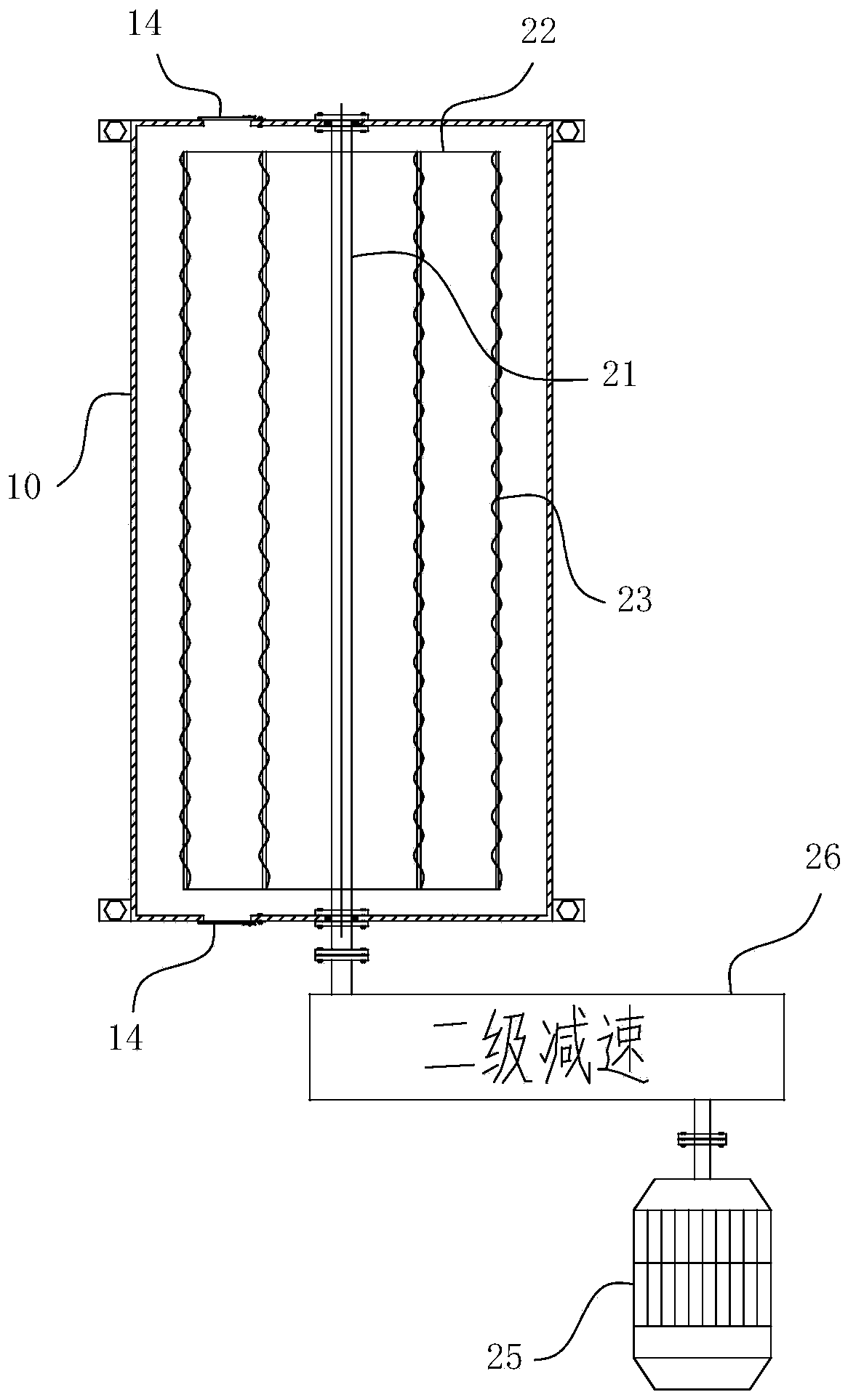

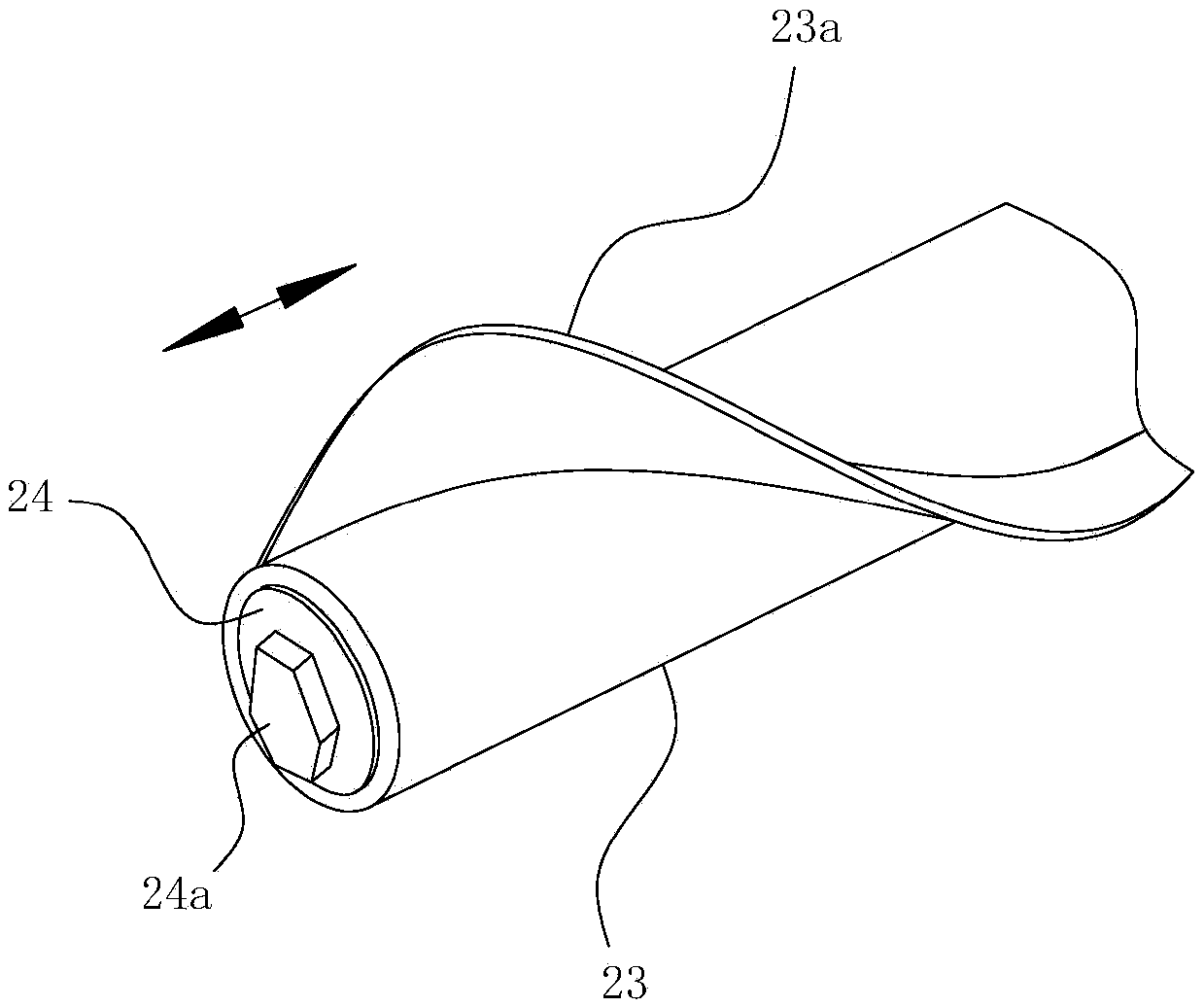

[0036] The specific structure of the present invention is as Figure 1-6 As shown, it includes an outer casing 10 arranged in a rectangular cylindrical shape after the dehydration process of the filter press. The upper port of the outer casing 10 constitutes the feed port 11 connected to the discharge end of the upper chute on the outside, and the lower port of the outer casing 10 constitutes a Connect the outlet 12 of the feed end of the lower chute to the outside. A stirring part is arranged inside the outer casing 10 to stir the coal slime. The shape of the stirring part is in the shape of a regular square prism frame, including a rotating shaft 21 penetrating through the outer shell 10 and forming a rotation fit with it. The rotating shaft 21 is externally connected to the power output part. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com