Camera SFR testing mechanism

A technology for testing institutions and cameras, applied in image communication, television, electrical components, etc., can solve the problems of low testing efficiency, waste of labor costs and equipment costs, and achieve the effect of saving labor costs and equipment costs and improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

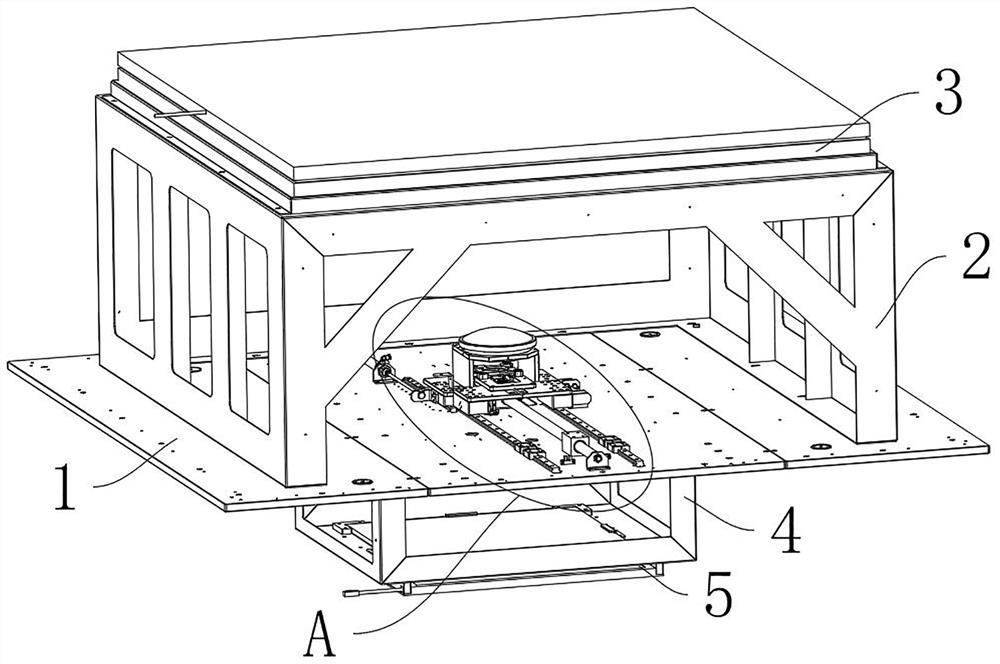

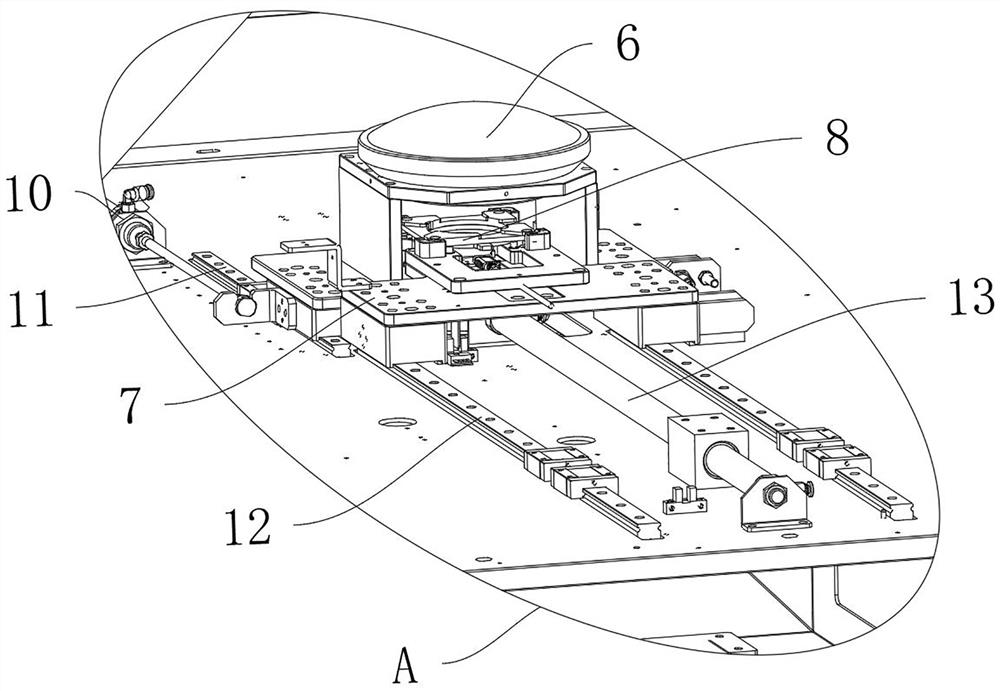

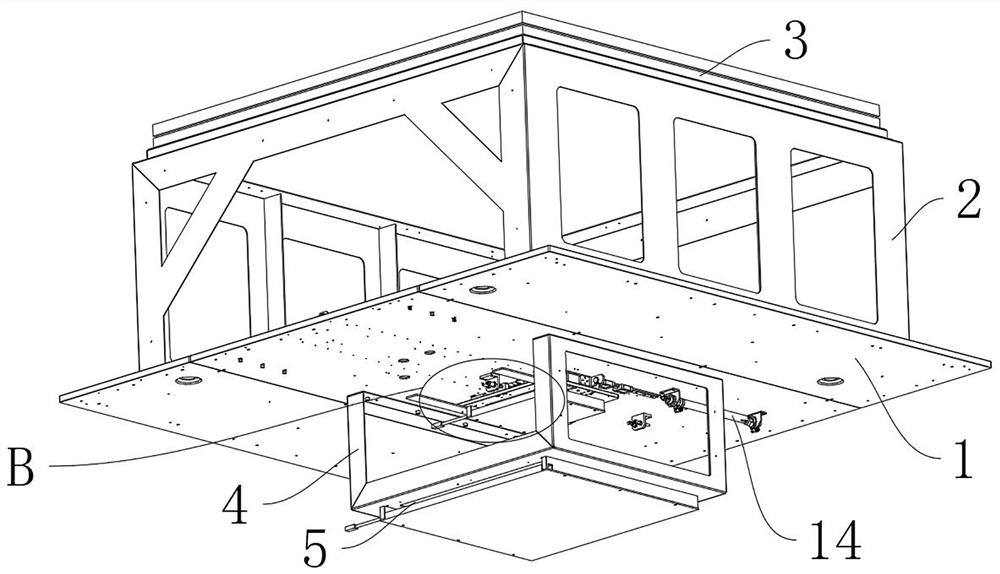

[0026] The embodiment of the present invention discloses a camera SFR testing mechanism, such as Figure 1-9 shown, including:

[0027] Substrate 1, the top of the substrate 1 is provided with a front camera assembly, the bottom end of the substrate 1 is provided with a rear camera close-range assembly, and the bottom end of the substrate 1 is provided with a rear camera perspective assembly outside the rear camera close-view assembly;

[0028] The front camera assembly includes a first image test card 3, the bottom of the first image test card 3 is provided with a first support frame 2, and the bottom of the first support frame 2 is fixedly connected to the top of the substrate 1;

[0029] The rear camera close-range assembly includes a second image test card 16, and the top of the second image test card 16 is provided with an auxiliary board 9;

[0030] The middle part of the bottom end of the base plate 1 is fixedly installed with two third slide rails 15, and the two thir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap