Method for producing modified pea protein

A manufacturing method and protein technology, applied in the protein composition of vegetable seeds, plant protein processing, protein food ingredients, etc., can solve the problem of adding protein glutaminase, etc., to achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

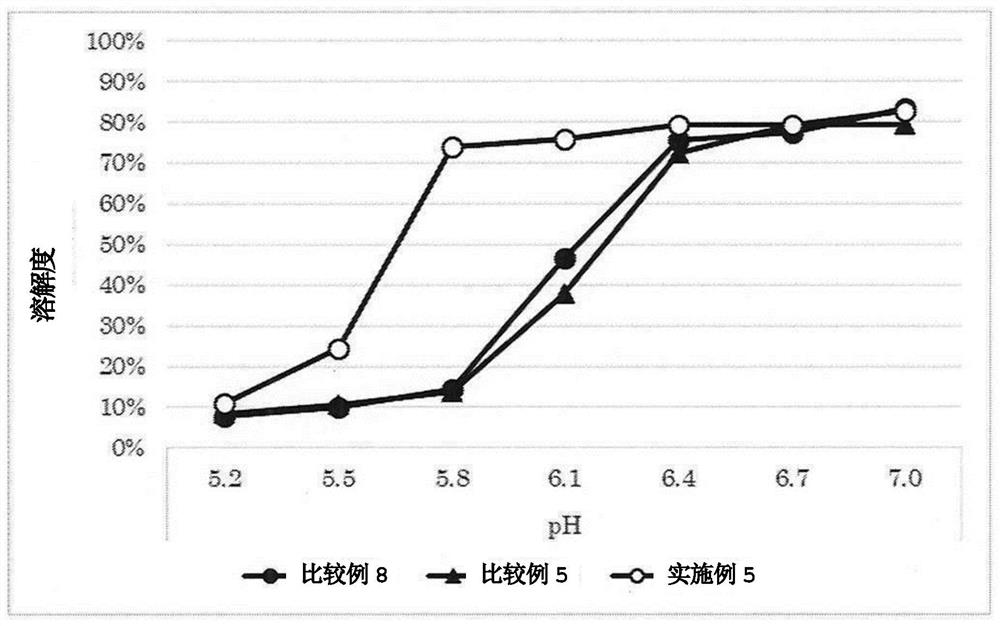

Embodiment 1

[0119] Add 85 parts by weight of water to 15 parts by weight of yellow pea powder obtained by dry crushing of yellow pea (the specification of the particle size is a powder whose D95 is measured by a laser diffraction-scattering particle size distribution measuring device) 15 parts by weight, Stir at 20° C. for 1 hour, perform centrifugation (6000 g×30 minutes) at 20° C., recover the supernatant and filter it with a paper filter (Whatman, 520B1 / 2FF) to obtain a pea solution. Hydrochloric acid was added to the obtained pea solution to adjust the pH to 4.5, stirred at 20° C. for 30 minutes, and centrifuged at 20° C. (6000 g×30 minutes) to recover the precipitate and obtain an isolated pea protein clot. 3 parts by weight of water were added to 1 part by weight of the obtained curd to disperse the curd, and sodium hydroxide was added to adjust the pH of the solution to 7.0 to dissolve the curd to obtain an isolated pea protein solution. Protein glutaminase was added to the obtaine...

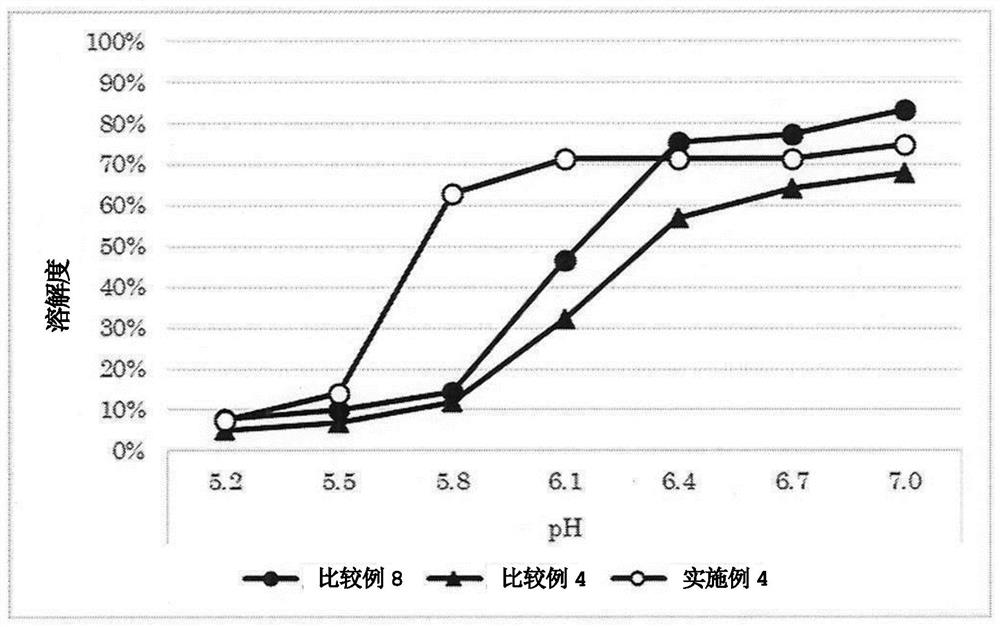

Embodiment 2

[0129] Add 85 parts by weight of water to 15 parts by weight of yellow pea powder obtained by dry crushing of yellow pea (the specification of the particle size is a powder whose D95 is measured by a laser diffraction-scattering particle size distribution measuring device) 15 parts by weight, Stir at 20° C. for 1 hour, perform centrifugation (6000 g×30 minutes) at 20° C., recover the supernatant and filter it with a paper filter (Whatman, 520B1 / 2FF) to obtain a pea solution. Hydrochloric acid was added to the obtained pea solution to adjust the pH to 4.5, stirred at 20° C. for 30 minutes, and centrifuged at 20° C. (6000 g×30 minutes) to recover the precipitate and obtain an isolated pea protein clot. 3 parts by weight of water were added to 1 part by weight of the obtained curd to disperse the curd, and sodium hydroxide was added to adjust the pH of the solution to 7.0 to dissolve the curd to obtain an isolated pea protein solution. Protein glutaminase was added to the obtaine...

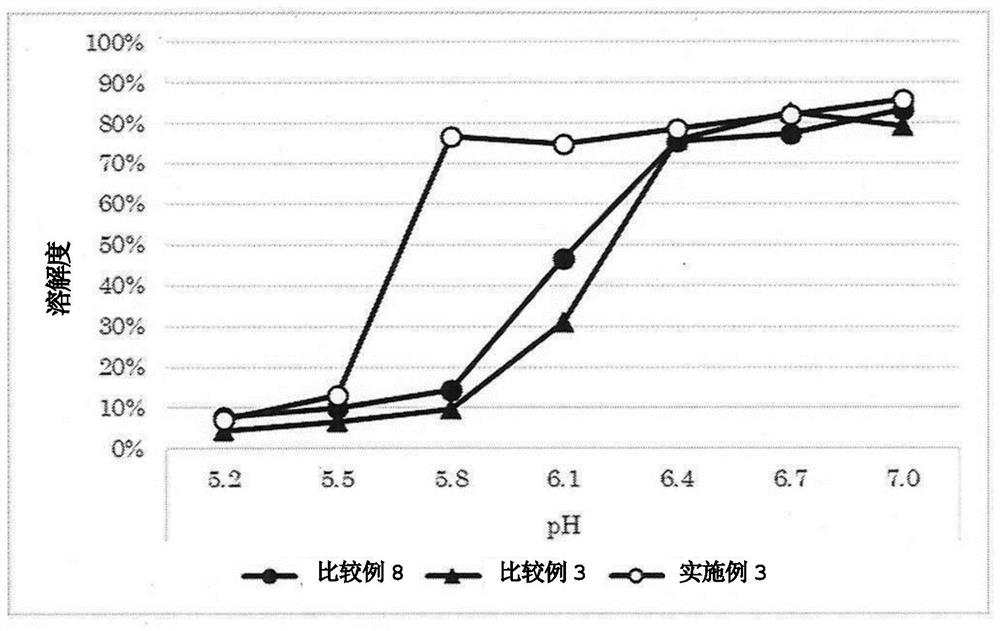

Embodiment 3

[0138] Add 85 parts by weight of water to 15 parts by weight of yellow pea powder obtained by dry grinding of yellow pea (particle size is a powder whose D95 is measured by a laser diffraction-scattering type particle size distribution measuring device) 15 parts by weight, to Protein glutaminase was added in an amount of 21 units per 1 g of protein, and stirred at 50° C. for 1 hour. Centrifugation was performed at 20° C. (6000 g×30 minutes), and the supernatant was recovered and filtered with a paper filter (Whatman, 520B 1 / 2FF) to obtain a pea solution. Hydrochloric acid was added to the obtained pea solution to adjust the pH to 4.5, stirred at 20° C. for 30 minutes, and centrifuged at 20° C. (6000 g×30 minutes) to recover the precipitate and obtain an isolated pea protein clot. 3 parts by weight of water were added to 1 part by weight of the obtained curd to disperse the curd, and sodium hydroxide was added to adjust the pH of the solution to 7.0 to dissolve the curd to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com