Resin composition for injection molding or compression molding

A resin composition and compression molding technology, which is applied in the field of resin compositions for injection molding or compression molding, can solve problems such as insufficient strength, difficulties in olefin copolymers, and difficulty in polymerization, and achieve excellent long-term durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0149] (preparation of samples)

[0150] For the sample, a 1 mg / mL solution was prepared using ODCB (0.5 mg / mL of BHT (containing 2,6-di-tert-butyl-4-methylphenol)), and dissolved at 140° C. for about 1 hour.

[0151] (calculation of molecular weight (M))

[0152] It was carried out by the standard polystyrene method, and the conversion from the retention capacity to the molecular weight was performed using a calibration curve based on standard polystyrene prepared in advance. The standard polystyrene used is, for example, commercial products manufactured by Tosoh Corporation (F380, F288, F128, F80, F40, F20, F10, F4, F1, A5000, A2500, A1000), monodisperse polystyrene manufactured by Showa Denko ( S-7300, S-3900, S-1950, S-1460, S-1010, S-565, S-152, S-66.0, S-28.5, S-5.05 each 0.07mg / ml solution), etc. A calibration curve was prepared by injecting 0.2 mL of a solution obtained by dissolving each standard polystyrene in ODCB (containing 0.5 mg / mL of BHT) so as to be 0.5 mg / m...

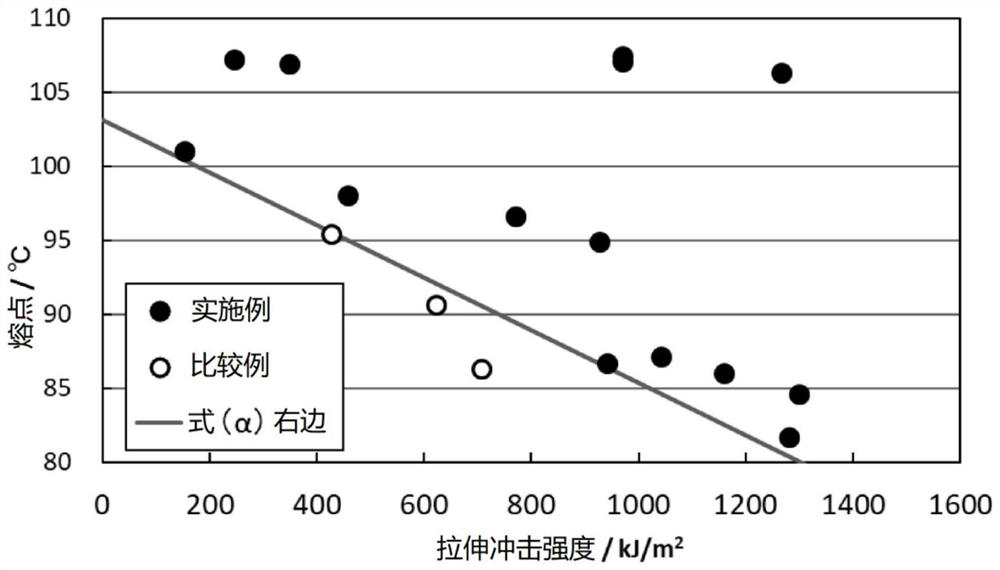

Embodiment

[0313] Examples and comparative examples are given below to describe the present invention more specifically, but the present invention is not limited to these examples.

[0314] In addition, the measurement and evaluation of the physical property in the Example and the comparative example were implemented by the method shown below.

[0315] In addition, no data in the table means that it has not been determined, and not detected means that it is below the detection limit.

[0316]

[0317] (1) Determination of the phase angle δ (G*=0.1MPa) at the absolute value of the complex modulus G*=0.1MPa

[0318] 1) Preparation and measurement of samples

[0319] Put the sample into a hot press mold with a thickness of 1.0mm, preheat it in a hot press with a surface temperature of 180°C for 5 minutes, and degas the residual gas in the molten resin by repeated pressurization and decompression. Pressurize at MPa and keep it for 5 minutes. Thereafter, it was transferred to a press hav...

manufacture example 1~ manufacture example 5

[0453]

[0454] Using transition metal complexes (B-27DM / Ni complex or B-423 / Ni complex), ethylene / t-butyl acrylate copolymers and ethylene / t-butyl acrylate / norbornene copolymers were produced. Referring to Production Example 1 or Production Example 3 described in Japanese Patent Application Laid-Open No. 2016-79408, the copolymer was produced, and the type of metal catalyst, the amount of metal catalyst, the amount of trioctylaluminum (TNOA), the amount of toluene, and the comonomer Table 1 shows the production conditions and production results with appropriately changed types, comonomer amounts, ethylene partial pressure, polymerization temperature, polymerization time, etc., and Table 2 shows the physical properties of the obtained copolymers.

[0455] [Table 1]

[0456] Table 1

[0457]

[0458] [Table 2]

[0459] Table 2 E / tBA / x copolymerization results

[0460]

[0461]

[0462] 40 g of the obtained copolymers of Production Examples 1 to 5, 0.8 g of p-toluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com