Plate sealing film for sealing full-skirt 96-hole reaction plate

A technology of reaction plate and plate sealing film, which is applied to specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, sterilization method, etc., which can solve the problems of difficult operation, cumbersome, low practicability, etc. , to achieve the effect of increasing friction, convenient installation and use, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

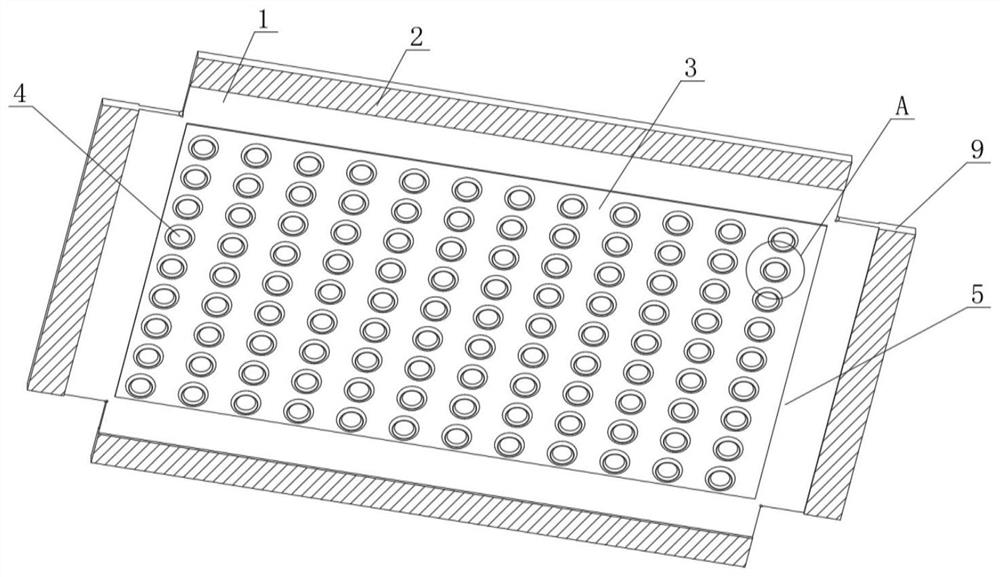

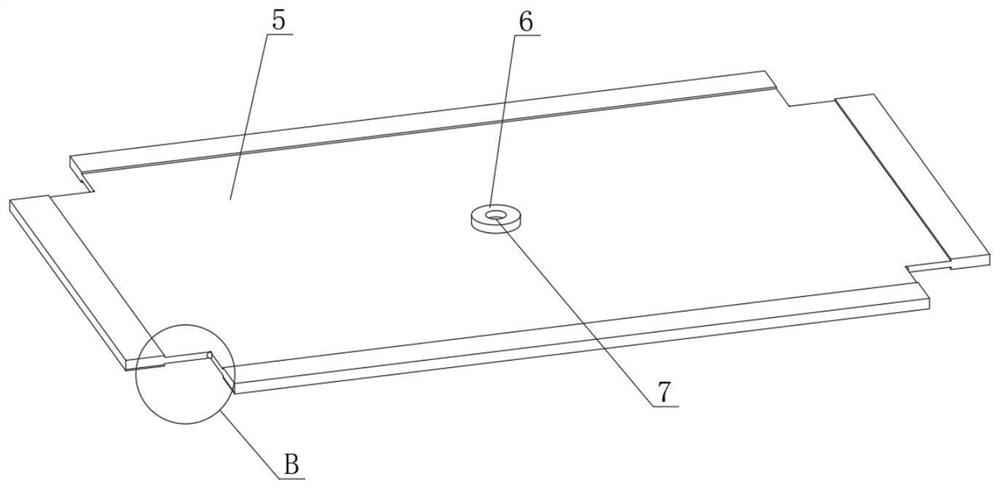

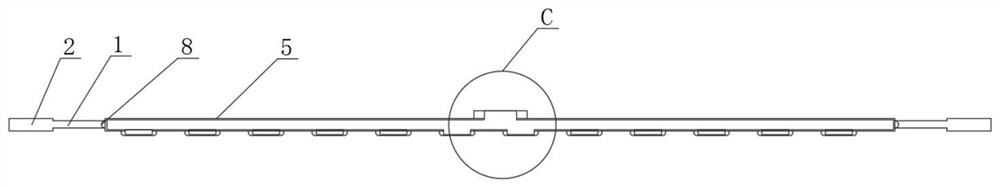

[0030] Such as Figure 1-7 As shown, a sealing film used for sealing a fully skirted 96-well reaction plate includes a square film 5, and the outer peripheral wall of the square film 5 is connected with edge sealing leaves 1, and the outside of each edge sealing leaf 1 is provided with Skirt board 9 is arranged, and the lower end of skirt board 9 is all provided with adhesive coating 10, and the lower end of each skirt board 9 is connected with edge banding sticky paper 2 through adhesive coating 10, and the lower end of square film 5 is connected There is a reaction plate sealing film 3, the reaction plate sealing film 3 is provided with several sealing components 4, the upper surface of the square film 5 is provided with an upper inflation cylinder 6, and the center of the upper inflation cylinder 6 is provided with an inflation hole 7.

[0031] According to the above technical scheme, first place the square film 5 on the full-skirted 96-hole reaction plate, then put the edg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap