Tunnel arch frame multi-shaft clamping and fixing device

A technology for fixing devices and tunnels, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of large installation limitations of steel arches and affect the assembly efficiency and quality of steel arches, so as to improve installation efficiency and quality, The effect of diversified functions and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

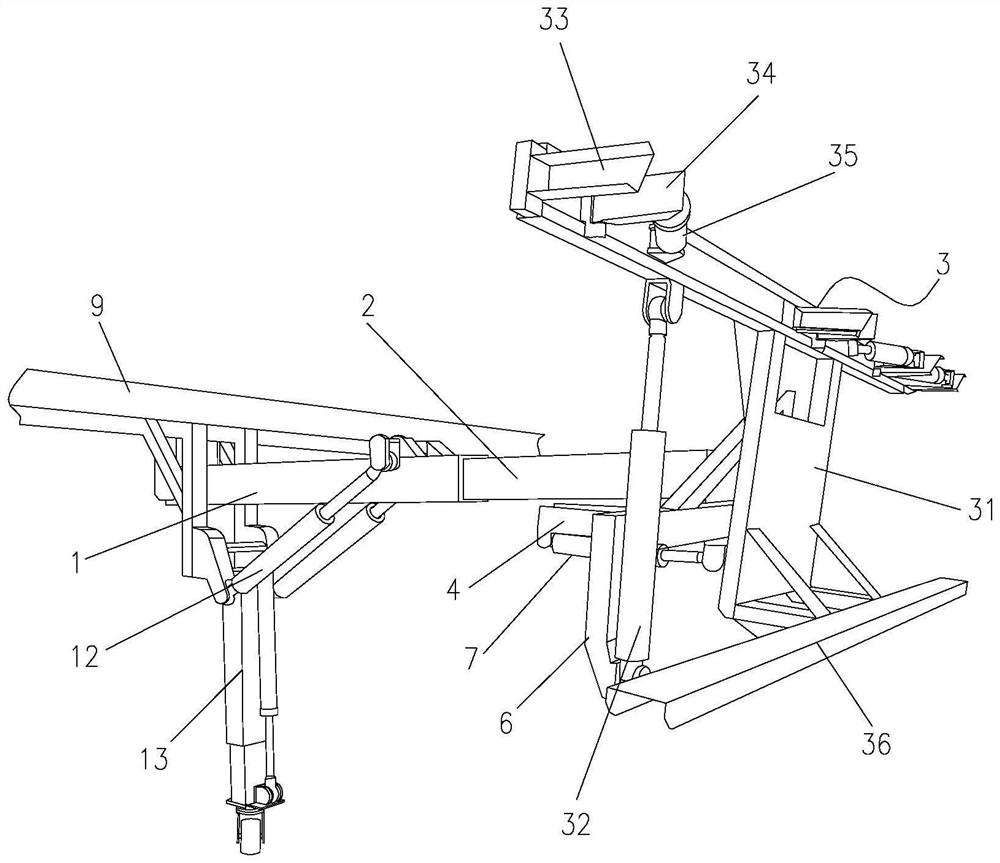

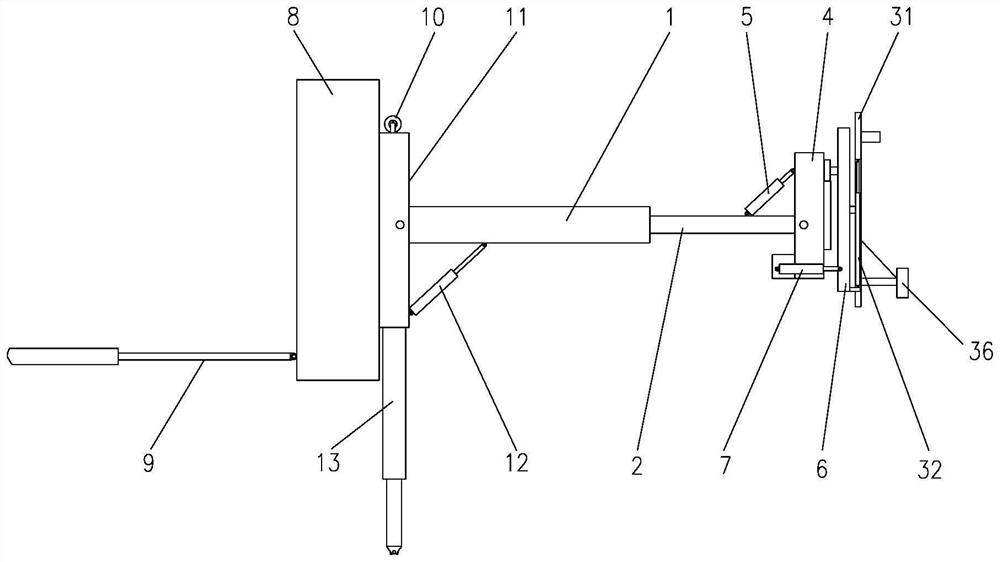

[0017] like Figure 1-2 As shown, the tunnel arch multi-axis clamping and fixing device of the present invention is applied to the tunnel arch machine, and it includes a telescopic boom 1, a telescopic small arm 2 and a clamping mechanism 3; the telescopic small arm 2 is slidably connected to the telescopic boom 1 The front end of the telescopic arm 2 is driven by the telescopic driver to expand and contract (located inside the telescopic arm 1 and the telescopic arm 2, not shown in the figure). A pitching driver 5 is driven to perform a pitching motion, and the front end of the pitching seat 4 is rotatably connected to a turntable 6, which is driven by the first turning driver 7 to rotate in plane A, and the clamping mechanism 3 includes a front end connected to the turntable 6. , the clamping mechanism 3 includes a panel 31, the panel 31 is rotatably connected to the turntable 6, and the panel 31 is driven by the second rotation driver 32 to rotate in the B plane (the B plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com