Evaluation method and evaluation device for wall thickness of nuclear-grade pipeline of in-service nuclear power station

An evaluation method and nuclear power plant technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as conservative results, achieve the effect of reducing conservatism, wide application range, and avoiding corrective maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

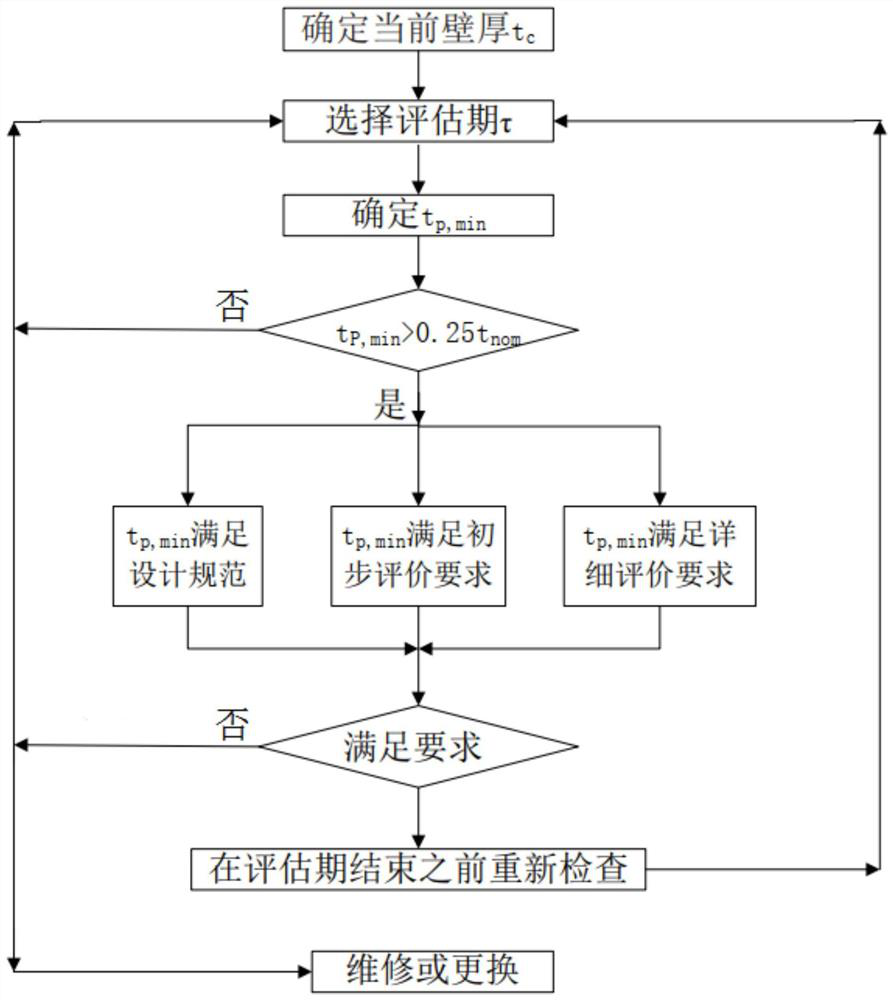

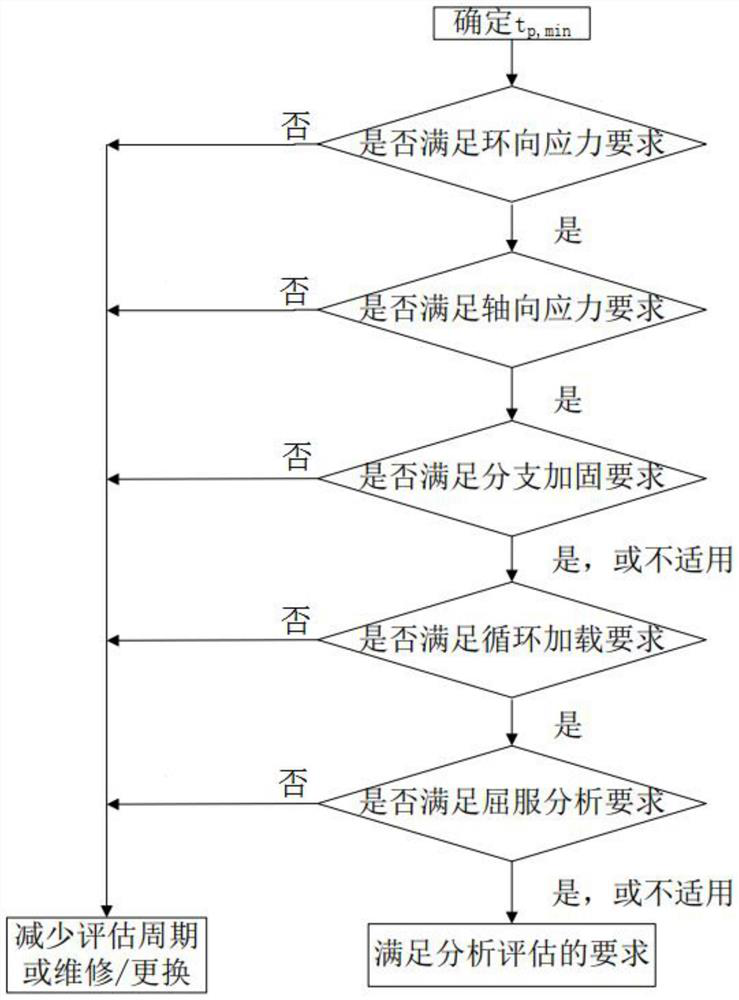

[0051] Such as figure 1 , figure 2 As shown, this embodiment discloses a method for evaluating the wall thickness of nuclear-grade pipelines in active nuclear power plants, which includes steps S0-S5:

[0052] S0, predict the wall thickness t of the pipeline at the next in-service inspection according to the current pipeline condition p,min .

[0053] Specifically, step S0 specifically includes: S1, detecting the wall thickness of the pipeline during this in-service inspection, and obtaining the current wall thickness t c ;S2, according to the current wall thickness t c , the wall thickness data of previous in-service inspections, and the evaluation cycle τ of in-service inspections (ie figure 1 evaluation period in ), predicting the wall thickness t of the pipeline at the next in-service inspection p,min , where the in-service inspection and evaluation cycle τ is determined according to the provisions of the nuclear power plant in-service inspection program, for example...

Embodiment 2

[0105] Such as Figure 4 As shown, this embodiment discloses an evaluation device for the wall thickness of a nuclear-grade pipeline in an in-service nuclear power plant, including a prediction module, a first judgment module, a second judgment module, and a third judgment module, wherein:

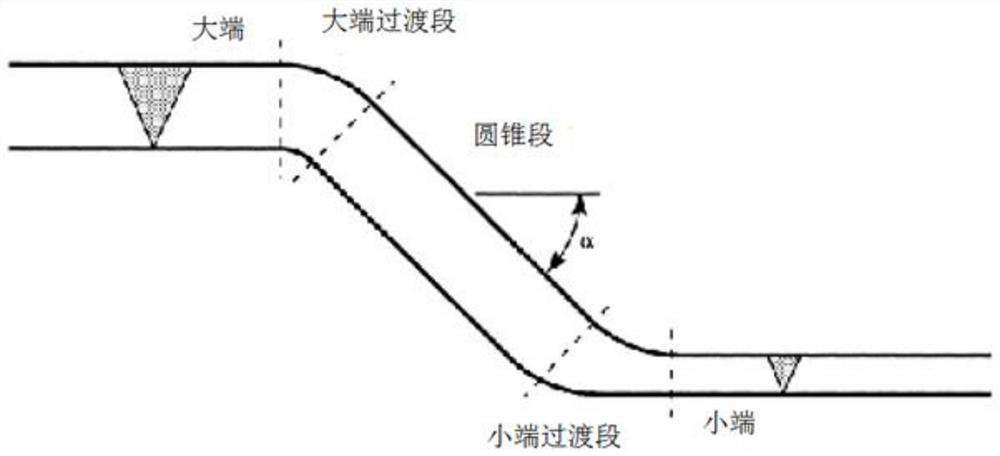

[0106] Prediction module for predicting the wall thickness t of the pipeline at the next in-service inspection based on the current pipeline condition p,min Specifically, pipelines include butt-welded pipelines, elbows, elbows, tees, branch pipe plugs, coaxial and eccentric joints, such as commonly used in the nuclear power industry. When the wall thickness is obtained, the current wall thickness t is obtained c , and then according to the current wall thickness t c , the wall thickness data of previous in-service inspections, and the in-service inspection evaluation period τ, predict the wall thickness t of the pipeline at the next in-service inspection p,min , where the in-service ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com