Efficient step end mill

A technology of end mills and steps, which is applied in the field of high-efficiency step end mills, can solve the problems of fast tool tip wear and short service life, and achieve the effects of improving milling processing efficiency, prolonging service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

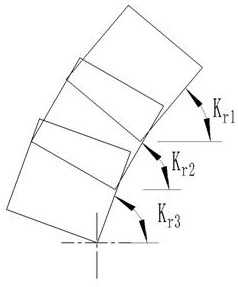

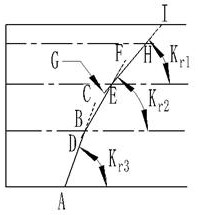

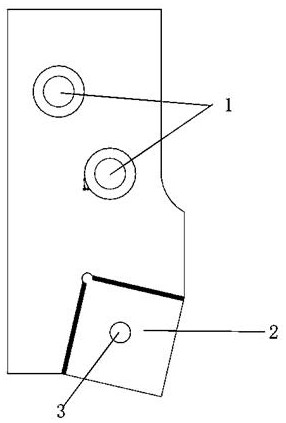

[0046] Such as Figure 1-Figure 9 As shown; now take 4 cutter groups on the cutter body, each group includes 3 cutter teeth as an example, that is, each group is divided into 3 steps, and the end mill has 12 tool seats and cutter teeth in total, which is a three-step end milling The blades of the same order have the same height and diameter, that is to say, the distances from the tip of the teeth of the same order to the end face of the cutter body are the same, and the distance to the axis of the cutter body is also equal, but the tips of the teeth of different stages are neither equal. The height is not equal to the diameter, that is, the distances from the tips of different stages of cutter teeth to the end face of the cutter body are not equal, and the distances from the axis of the cutter body are also not equal.

[0047] According to the relevant regulations of the national standard, the tool nose radius R of the third-order cutter tooth 3 , Tool tip height H 3 and cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com