Jig Saw

A jigsaw and saw blade technology, which is applied in the field of hand-held jigsaws, can solve the problems of whether the teeth are staggered or not, the free cutting of the saw blade cannot be achieved, and the free cutting effect is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

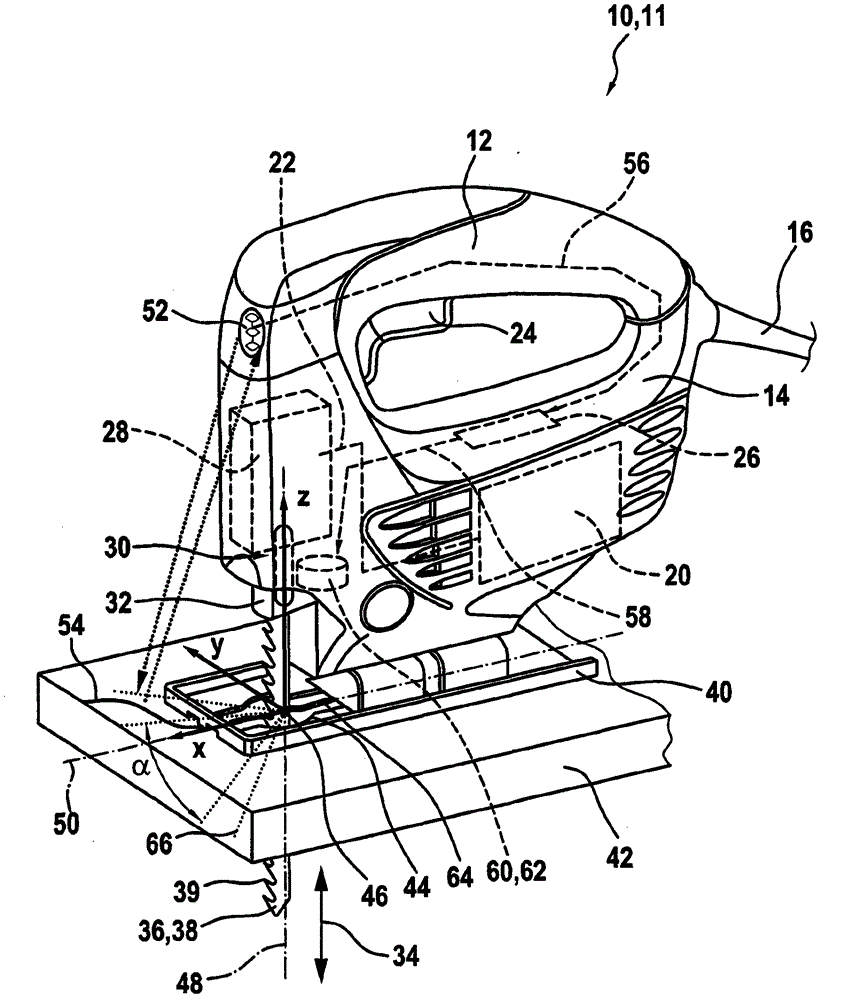

[0030] figure 1 A hand-held jigsaw 10 is shown, which is designed, for example, in the manner of a semi-automatic hand-held jigsaw 11 and has a tool housing 14 provided with a handle 12 in the form of a handle. The semiautomatic jigsaw 11 is preferably provided with a flexible electrical connection 16 for a networked power supply. It should be noted, however, that the invention is not limited to hand-held semi-automatic jigsaws 11 operable over a network, but can also be applied to all types of jigsaws operable without a network, for powering these jigsaws The saw can also be connected, for example mechanically and electrically, to an associated battery pack. Furthermore, it should be noted that the invention is also not limited to jigsaws with a tool housing forming a grip handle, but can also be applied to jigsaws with a bar-shaped tool housing.

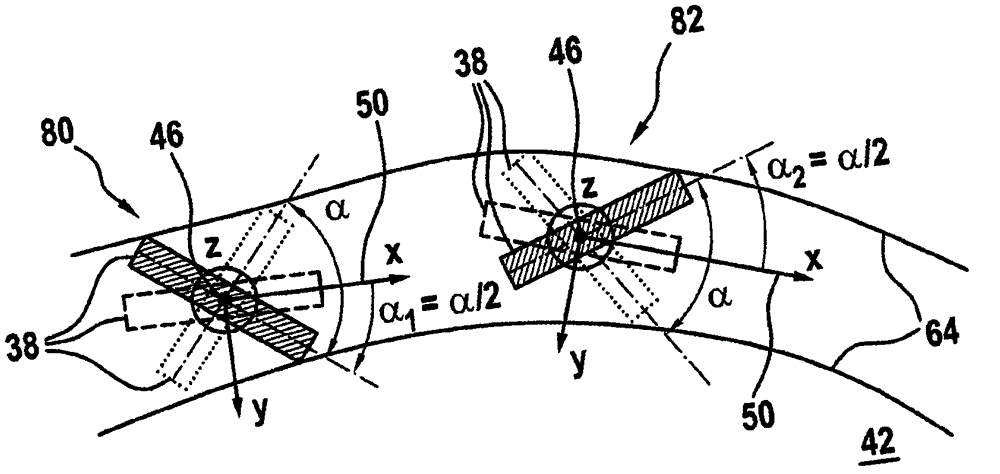

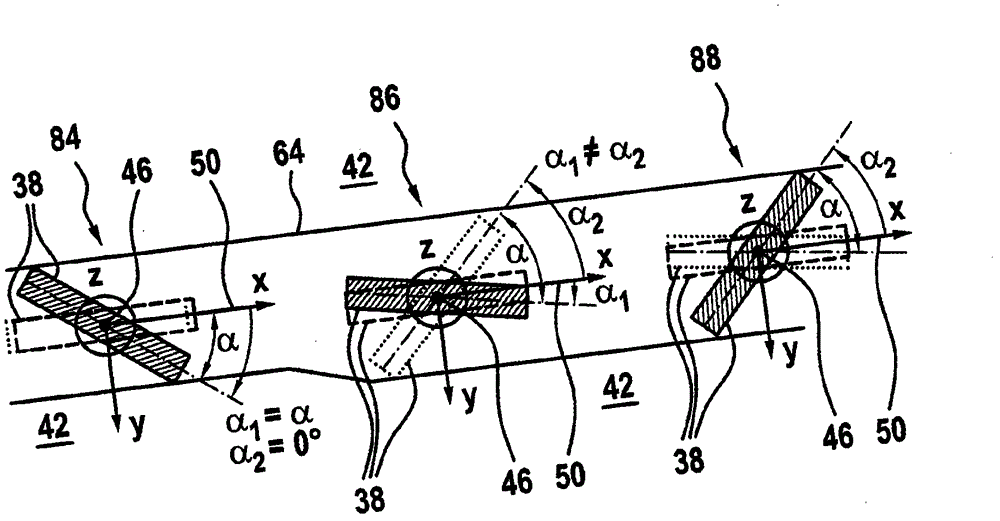

[0031] By way of example, a drive motor 20 for driving a drive shaft 22 is arranged in the tool housing 14 . The drive motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com