A method for making weak interlayers with adjustable thickness of existing original rock structural planes

A technology of weak interlayer and production method, which is applied in the field of indoor direct shear test, can solve the problems of difficult adjustment of the thickness of the soft interlayer, difficulty in making and laying the soft interlayer, and achieve the effect of free shearing and shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0078] (1) Field sampling. The hanging wall structural surface sample 6 and the footwall structural surface sample 8 of the original rock structural surface were obtained in the field.

[0079] (2) Base plate 1 is placed. Place base plate 1 on level ground.

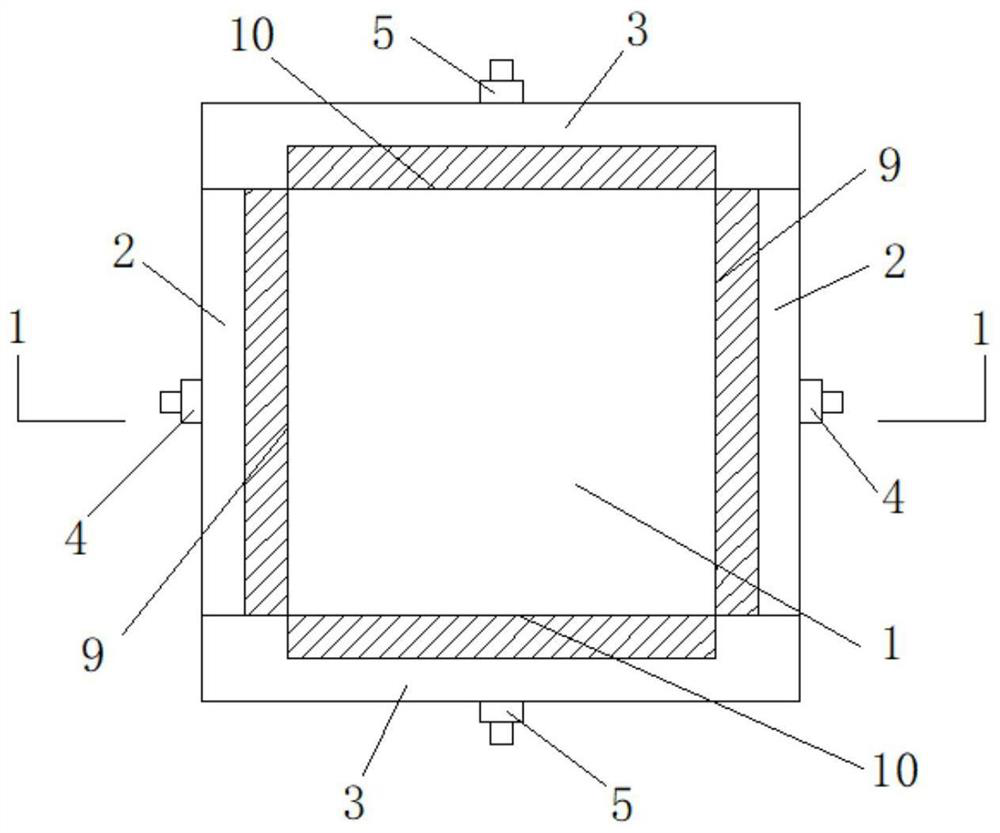

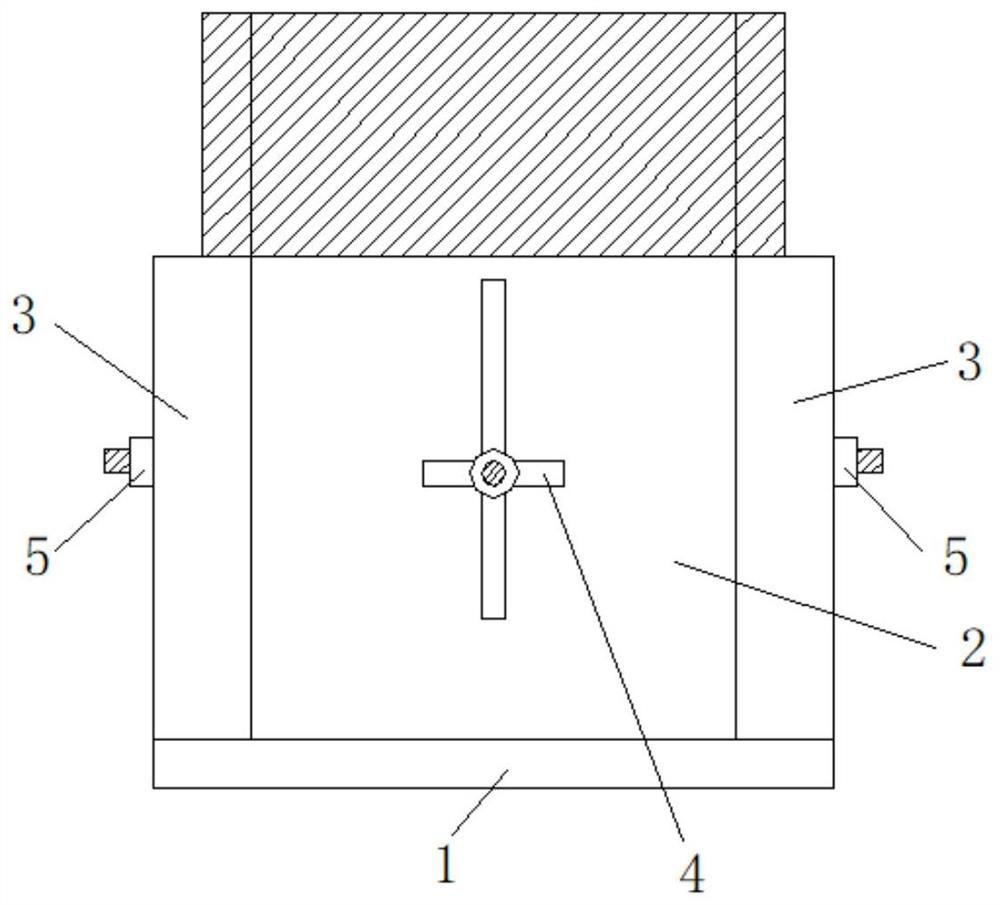

[0080] (3) Installation of four expansion boards. Two A-type expansion plates 2 and two B-type expansion plates 3 are symmetrically placed on the base plate 1 in pairs, and the four expansion plates are connected and fixed on the base plate 1 through expansion plate positioning columns 101 (at this time, among the four expansion plates The telescopic plate slider is in the state of not sliding out).

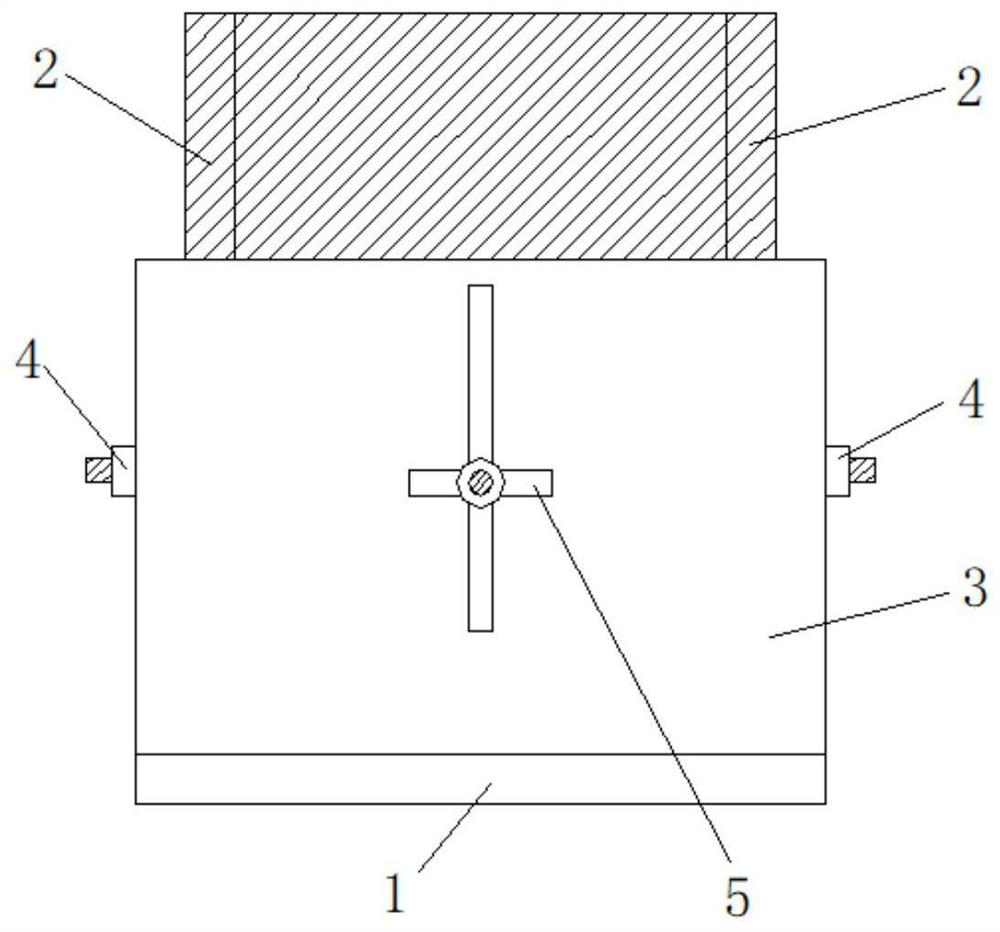

[0081] (4) Place sample 8 on the lower wall of the structural surface of the original rock. Place the sample 8 of the lower wall of the original rock structural surface in the assembled supporting device.

[0082] (5) Determination of the thickness of the weak interlayer 7 . The thickness of the weak interlayer 7 requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com