Test device and method for measuring ultimate bearing capacity of open caisson pipe pile composite anchorage

A technology of ultimate bearing capacity and test equipment, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of complex experimental operation, long cycle, complex design, etc., and achieve simple operation, low cost and simple measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, anti-pulling device.

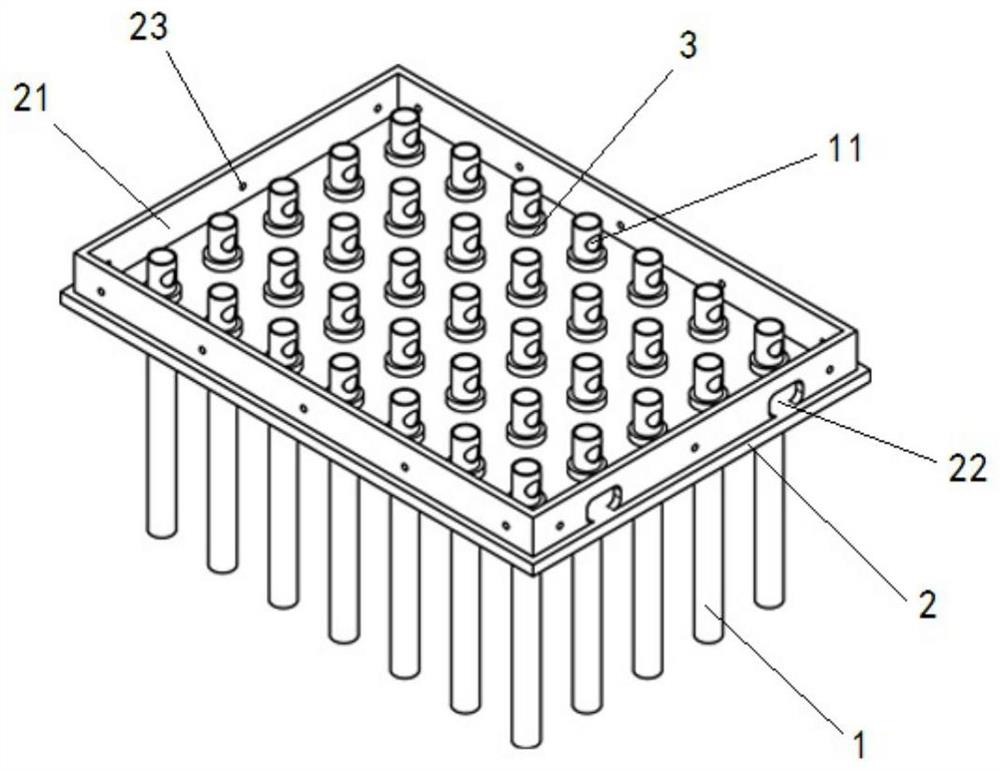

[0043] Refer to attached figure 1 , this embodiment provides an anti-pull device with pile group as the test object, its purpose is to prevent the pile group from detaching from the caisson floor during the process of being subjected to tension in the test, so as to ensure the accuracy and effectiveness of the pull-out test .

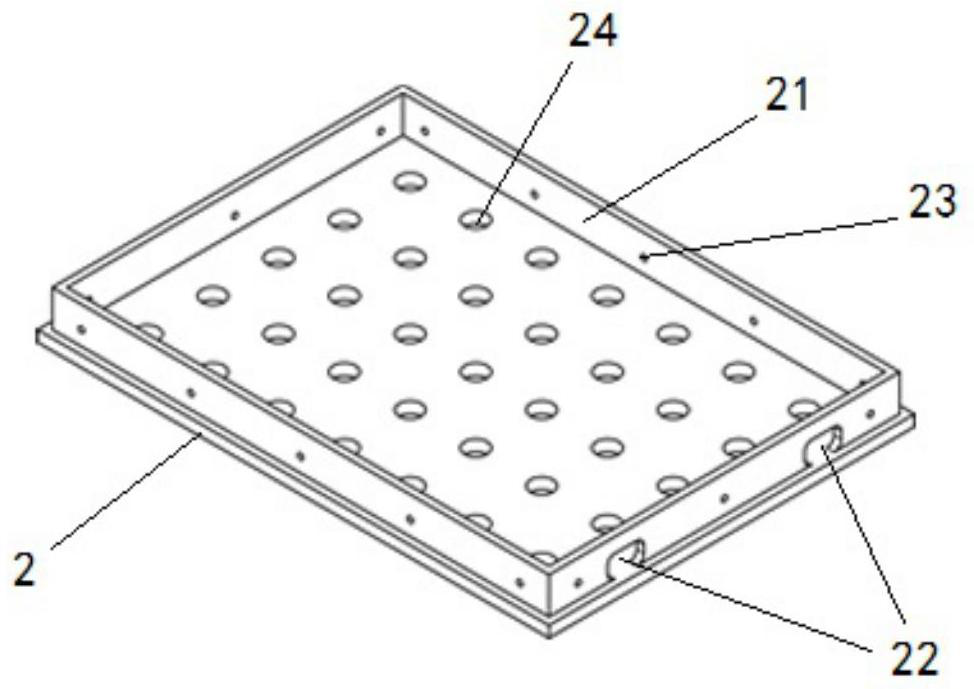

[0044] Such as figure 1 As shown in the figure, a plurality of pipe piles 1 are arranged according to certain rules to form a regular pile group, strain gauges are arranged outside the pipe piles 1, and pipe pile lead holes 11 are provided on the upper end side of the pipe piles 1; The upper part of the pile group is set with a caisson bottom plate 2, and the caisson bottom plate 2 is provided with a reserved pile hole 24, which corresponds to the size and position of the pipe piles 1 in the pile group, so that The pipe piles 1 can respectively penetrate into the reserved pile holes 21, and are fixedly conn...

Embodiment 2

[0048] Embodiment 2, anti-pressure device.

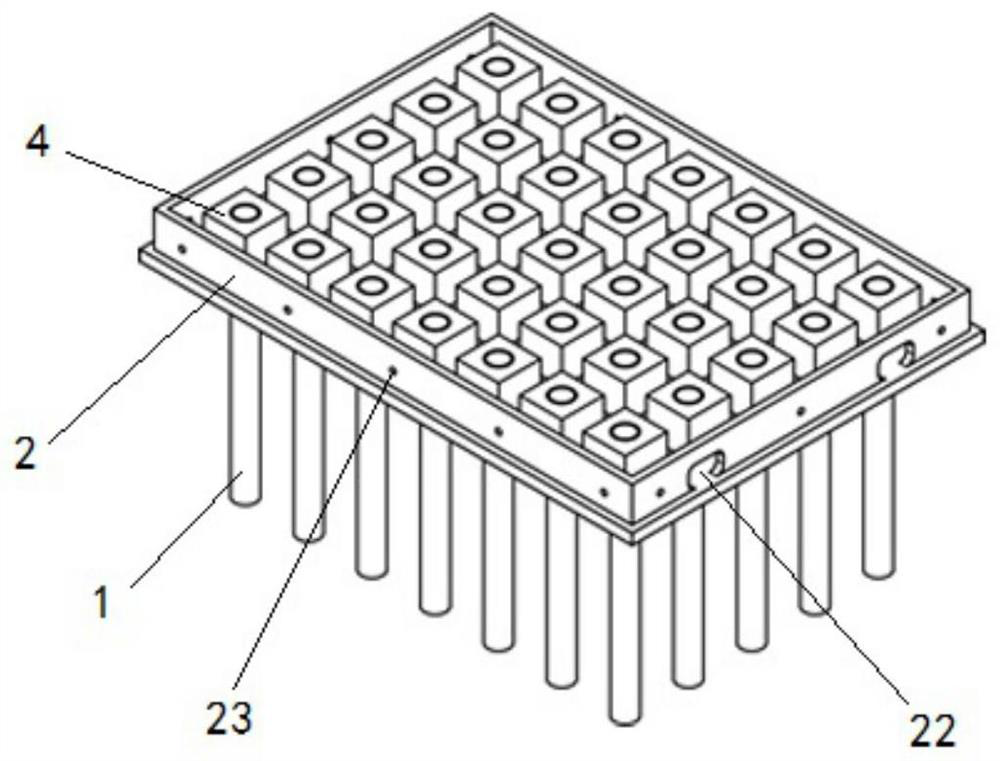

[0049] Refer to attached figure 2 , this embodiment further provides an anti-pressure device on the basis of embodiment 1.

[0050] In the pullout device of embodiment 1, high-strength gypsum 4 is poured on the top of the exposed pipe pile 1. When pouring high-strength gypsum 4, the caisson counterweight plate 5 must be covered before the high-strength gypsum 4 solidifies to ensure The top of each pipe pile 1 is subjected to the vertical load from the caisson counterweight plate 5, and the elevation error of the pipe pile 1 can be controlled within 2 mm (the caisson counterweight plate 5 is a part of the caisson structure and will be Further described in the Examples below).

[0051] Other implementation modes of this embodiment are the same as Embodiment 1.

Embodiment 3

[0052] Embodiment 3, counterweight structure.

[0053] Refer to attached Figure 4 , this embodiment further provides a counterweight structure on the basis of embodiment 2.

[0054] On the top of the anti-pressure device of embodiment 2, cover a caisson counterweight plate 5, the caisson counterweight plate 5 is fixedly connected with the upper surface of the side wall 21 by downward screws, the outer contour shape of the caisson counterweight plate 5 It is consistent with the outer contour of the side wall 21, and forms such as Figure 4 Flat sides shown.

[0055] The upper surface of the caisson counterweight plate 5 is fixedly provided with a caisson counterweight compartment 6, the size and number of grids of the caisson counterweight compartment 6 can be designed according to specific needs, and weights can be added to the caisson counterweight compartment 6, The purpose of the counterweight is to ensure that the size and center of gravity of the self-weight load of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com