Generator stator slot wedge tightness detection device

A generator stator and detection device technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of consuming manpower and material resources, long detection cycle, and inability to keep repeatable query data records, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better illustrate the technical solutions of the embodiments, the accompanying drawings of the description are further described below.

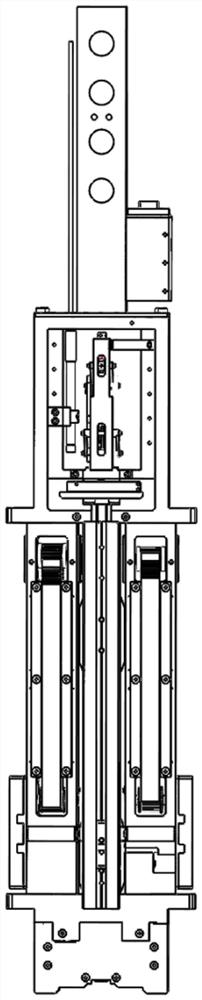

[0022] figure 1 is the top view of the wall-climbing robot for detection in the bore of the generator stator. The installation and combination form of the slot wedge tightness detection module and the ultra-thin wall-climbing robot is shown.

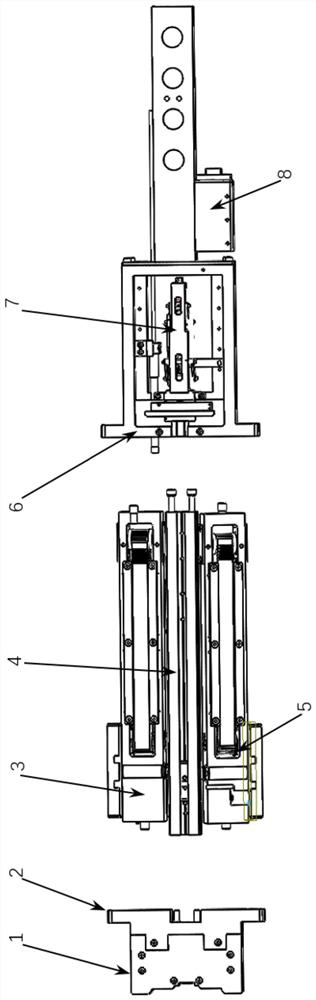

[0023] figure 2 It is the top view of the frame structure of the ultra-thin wall-climbing robot for detection in the bore of the generator stator. The frame structure and various modules of the wall-climbing robot are displayed. It includes a head camera module, a drive module and a slot wedge tightness detection module.

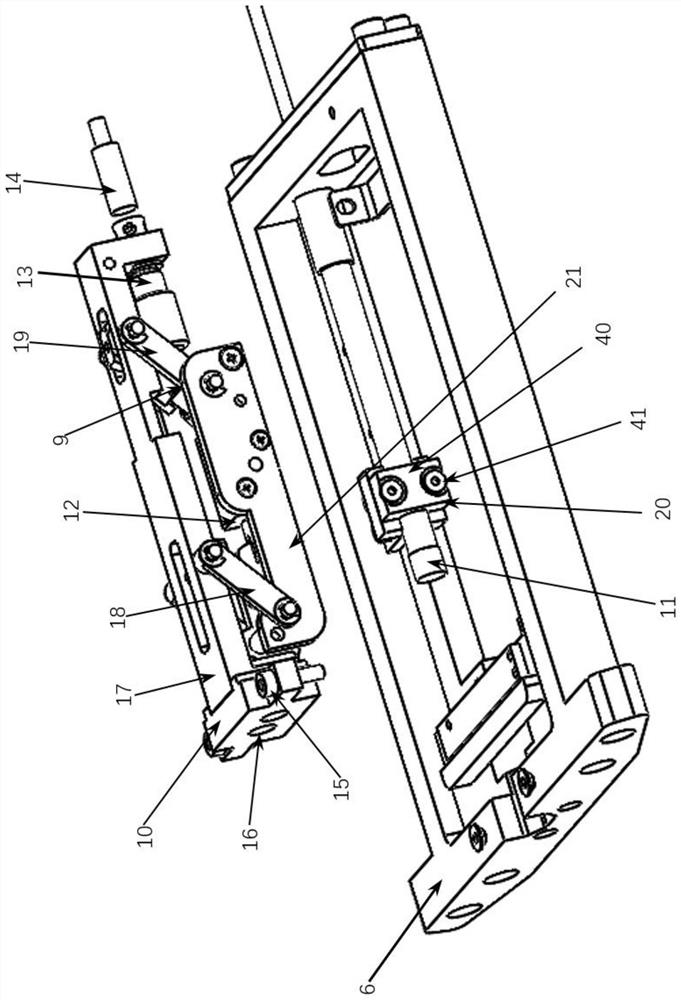

[0024] image 3 It is a diagram of the overall structure and installation form of the automatic detection device for stator wedge tightness of the generator, showing the main components of the automatic detection device for the stator wedge tightness of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com