A die steel strength testing device

A technology for strength testing and steel plates, applied in the field of testing, can solve the problems of wrong steel plate strength records, time-consuming and labor-intensive, people being scratched by steel plates, etc., to improve reliability, reduce manual participation, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

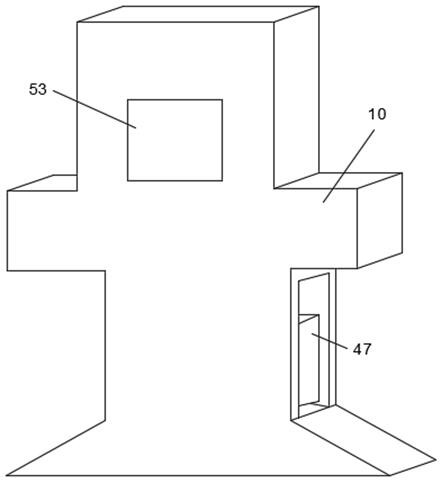

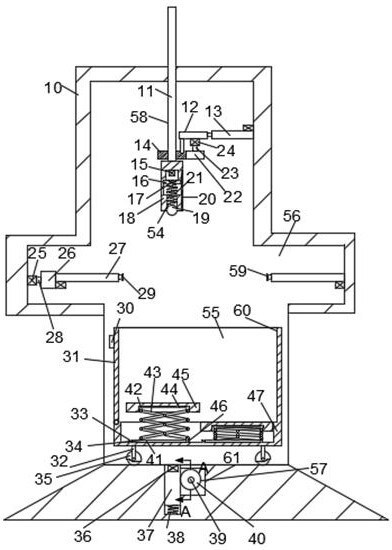

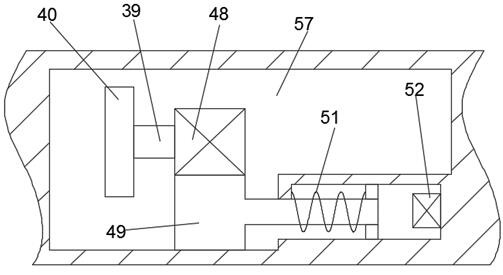

[0018] refer to Figure 1-4 , according to an embodiment of the present invention, a die steel strength detection device includes a casing 10 and a storage frame 47, an electronic screen display 53 is provided inside the casing 10, and a device communicating with the outside world is provided inside the casing 10. The functional cavity 56 of the storage frame 47 is provided with a tightening cavity 55 communicating with the outside world. The right end wall of the functional cavity 56 is fixedly connected with a cylinder 13, and the cylinder 13 is fixedly connected with a fixed block 12. The fixed block 12 The lower end surface is provided with a ball rod, and the ball rod is slidably connected with a driven gear 14, and the driven gear 14 is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com