Electric spiral slot puncher

A technology of electric screw punching machine, which is applied in the field of electric screw punching machine, can solve the problems of inaccurate stop position of the punch head, inconvenient picking and placing of slices, and many transmission parts, etc., to achieve extended life, compact structure, and easy operation. The effect of process smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

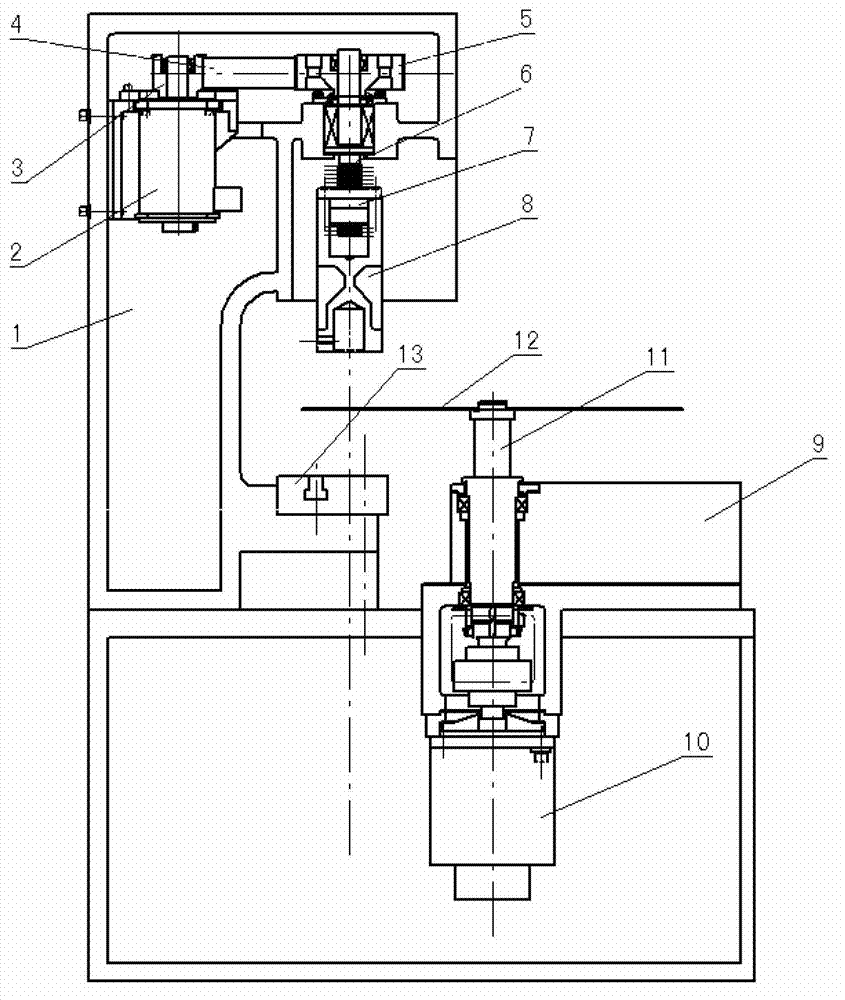

[0012] Such as figure 1 As shown, the electric spiral punching machine includes a fuselage 1, a slide block 8 is arranged on the fuselage 1, a servo motor 2 is installed on the top of the fuselage 1, and a small synchronous pulley 3 is installed on the output shaft of the servo motor 2, The small synchronous pulley 3 drives the large synchronous pulley 5 through the transmission of the synchronous belt 4, the large synchronous pulley 5 is equipped with a screw 6, the screw 6 rotates in the screw nut 7, and the screw nut 7 is fixed on the slider 8 The bottom of the fuselage 1 is equipped with an indexing device 9, and the indexing device 9 includes an indexing servo motor 10 and a vertical centering head 11 connected with the indexing servo motor 10, and an iron chip is installed on the upper end of the centering head 11 12. A workbench 13 facing the slider 8 is installed under the side of the core sheet 12.

[0013] The screw nut 7 converts the rotary motion of the screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com