A 3D cotton core production process

A production process and cotton core technology, applied in the field of disposable hygiene products, can solve the problems of low absorption rate of cotton core, high production cost of cotton core, uncomfortable wearing of cotton core, etc., and achieve high liquid absorption rate, high utilization rate, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

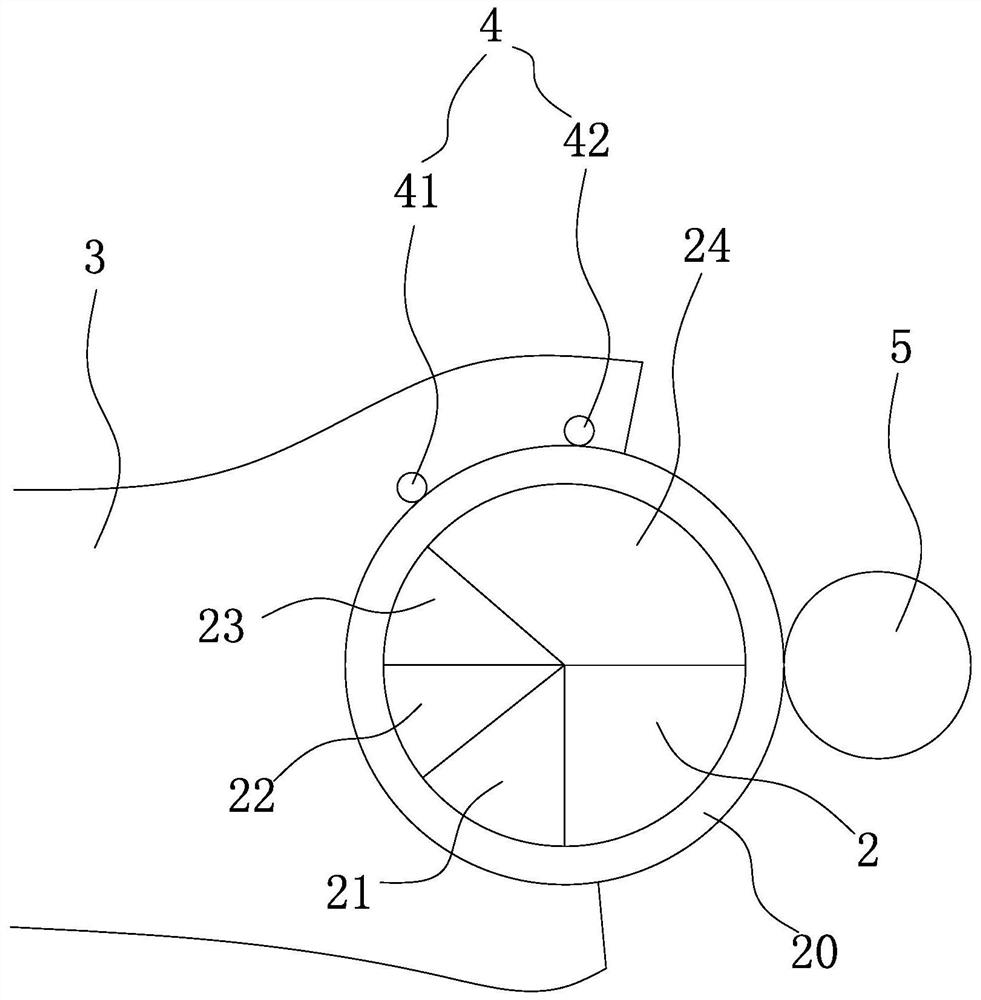

[0028] refer to Figure 1 to Figure 5 , the present embodiment provides a 3D cotton core manufacturing process, comprising the following steps:

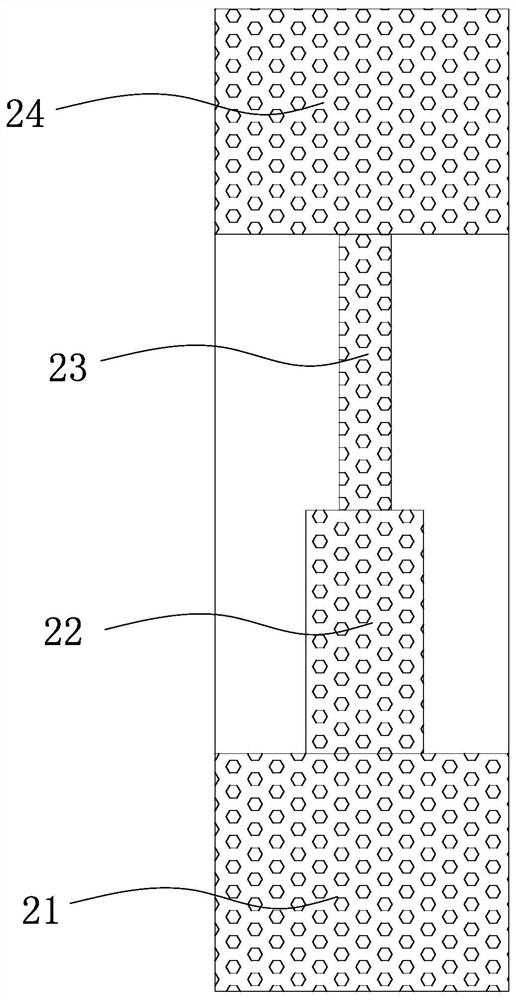

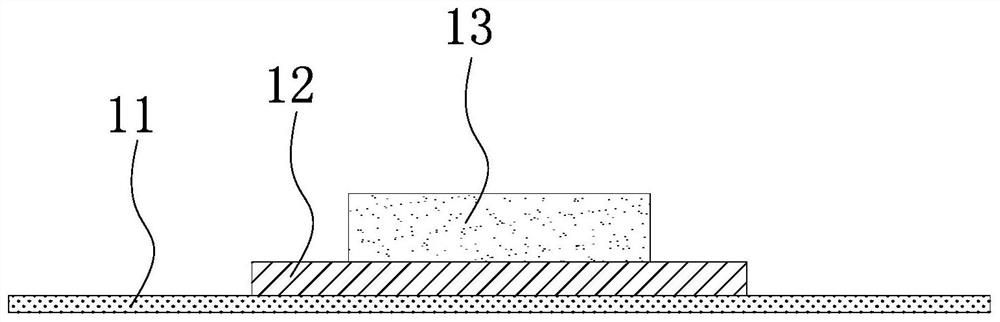

[0029] (1) Forming the first cotton core layer: the driving mechanism drives the cavity of the die wheel to rotate, and the die wheel 2 is provided with a plurality of die cavities. When the die cavity 20 rotates to the first adsorption cavity 21 of the die wheel, the polymer lowers The feeding mechanism 3 drops the polymer material into the cavity of the die wheel, and the first cotton core layer 11 is formed in the cavity;

[0030] (2) Forming the second cotton core layer: when the mold cavity rotates through the second adsorption cavity 22 of the die wheel, the adsorption force of the second adsorption cavity is greater than the adsorption force of the first adsorption cavity, and the polymer feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com