A kind of oil shale semi-coke adsorption inhibitor and its application in concrete preparation

A technology of oil shale semi-coke and inhibitor, which is applied in the application of the adsorption inhibitor in concrete preparation, and in the field of oil shale semi-coke adsorption inhibitor, which can solve the problems of concrete workability, poor workability, and limitations The resource utilization of oil shale semi-coke and the impact on site pouring construction have achieved the effect of reasonable formula design, high-value resource utilization and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

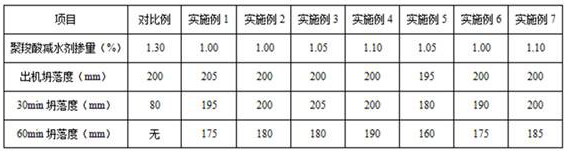

Examples

Embodiment 1

[0026] A kind of oil shale semi-coke adsorption inhibitor provided by the present embodiment is to combine 52 parts by weight of anti-corrosion rheology agent, 5 parts of methanol, 2 parts of sulfonated melamine, 5 parts of EDTA, 30 parts of high fluorine sodium siliconate and A mixture of polymethylvinyl siloxane with a mass ratio of 5:1 and 6 parts of stearate are sequentially added into a mixing container and fully stirred evenly.

[0027] The dosage of the adsorption inhibitor in the oil shale semi-coke is 0.05%.

Embodiment 2

[0029] A kind of oil shale semi-coke adsorption inhibitor provided by the present embodiment is 50.5 parts by weight of anti-corrosion rheology agent, 10 parts of methanol, 1.5 parts of sulfonated melamine, 3 parts of EDTA, 25 parts of organosilicon compound (methanol) Sodium siliconate, sodium high fluorine siliconate and cyclopentyl methacrylate-cubic oligomeric silsesquioxane nanocomposite at a mass ratio of 2:2:1), 10 parts of stearate were added and mixed in sequence In the container, stir thoroughly to obtain evenly.

[0030] The dosage of the adsorption inhibitor in the oil shale semi-coke is 0.08%.

Embodiment 3

[0032] A kind of oil shale semi-coke adsorption inhibitor provided by the present embodiment is 50.5 parts by weight of anti-corrosion rheology agent, 15 parts of methanol, 1.5 parts of sulfonated melamine, 3 parts of EDTA, 25 parts of organic silicon compound (methanol) Sodium siliconate, sodium high fluorine siliconate and cyclopentyl methacrylate-cubic oligomeric silsesquioxane nanocomposite in a mass ratio of 2:1:2), 5 parts of stearate were added and mixed in sequence In the container, stir thoroughly to obtain evenly.

[0033] The dosage of the adsorption inhibitor in the oil shale semi-coke is 0.10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com