Steering engine virtual debugging method and device thereof, terminal equipment and readable storage medium

A debugging method and steering gear technology, applied in the direction of design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of complex debugging process, high debugging cost and high construction cost, so as to reduce debugging costs, reduce learning costs, and reduce debugging costs. Simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

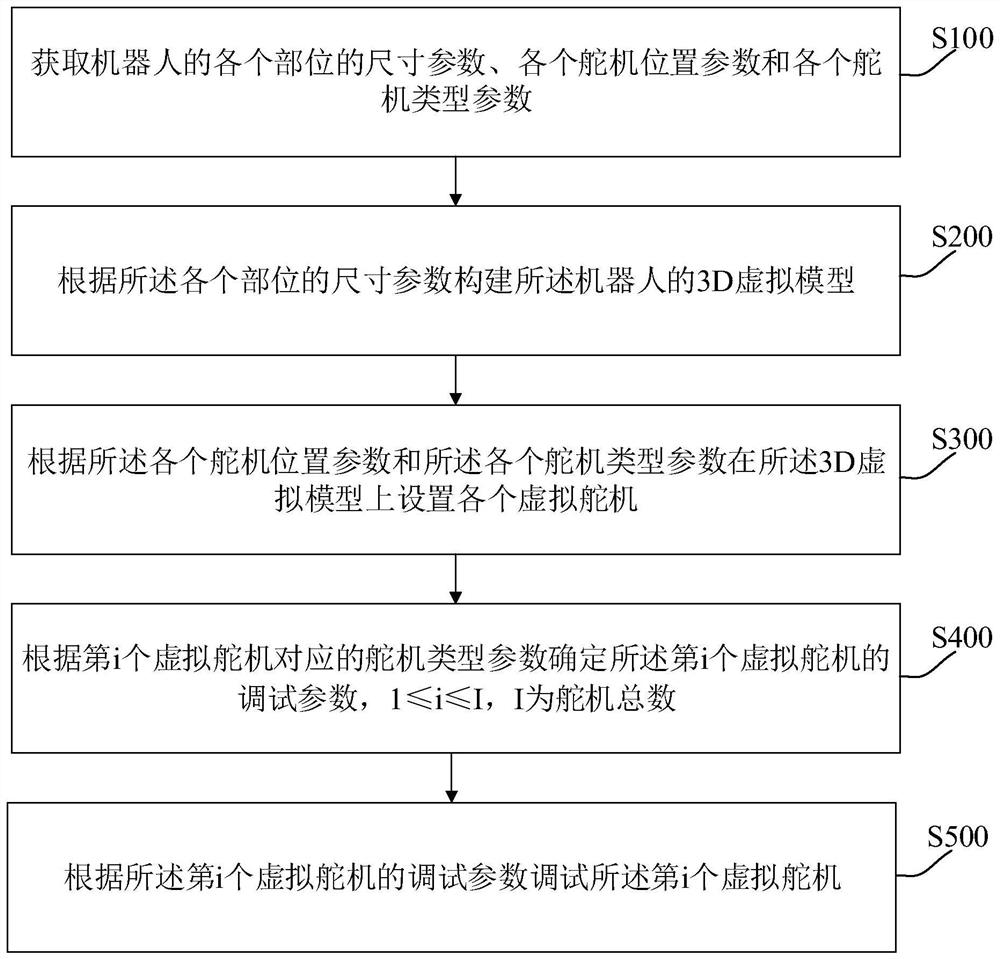

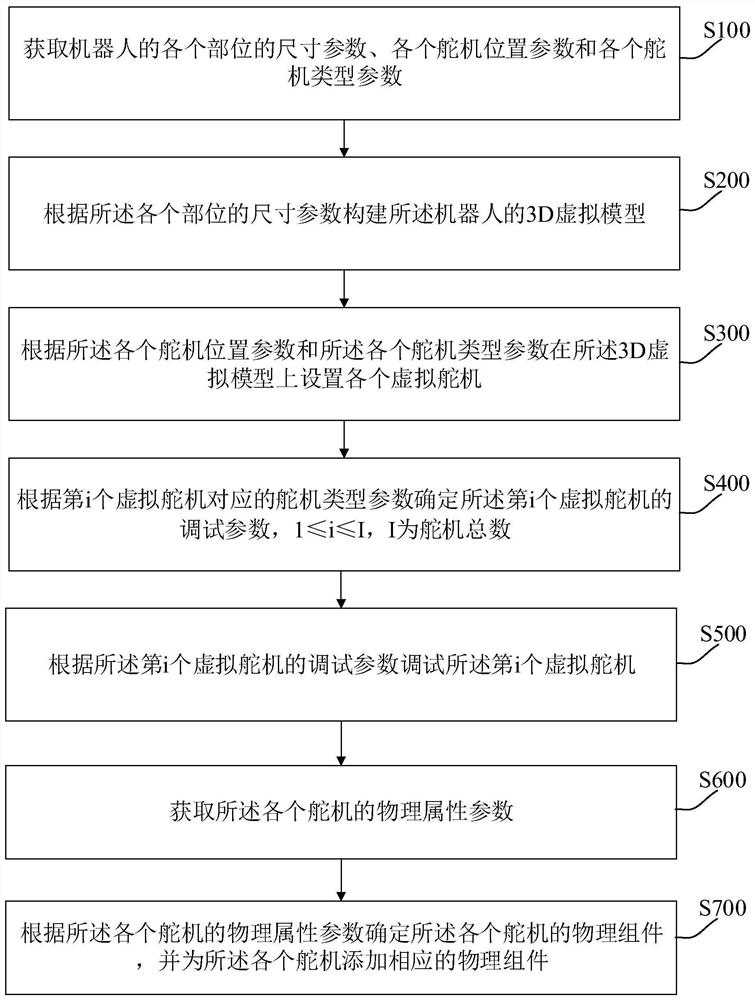

[0048] See figure 1 , an embodiment of the present application proposes a steering gear virtual debugging method, which is applied to a terminal device and realizes the virtual debugging of the steering gear through the terminal device. The method includes the following steps S100-S500:

[0049] In step S100, the size parameters of each part of the robot, the position parameters of each steering gear, and the type parameters of each steering gear are obtained.

[0050] The size parameters of each part of the robot, the position parameters of each steering gear, and the type parameters of each steering gear can be obtained from the product manual of the robot or the robot development requirements book.

[0051] For example, if it is a humanoid robot, it is necessary to obtain the size parameters of key parts such as the robot's arms, hands, legs, feet, head, and neck.

[0052] The position parameters of each steering gear include which parts of the robot each steering gear is lo...

Embodiment 2

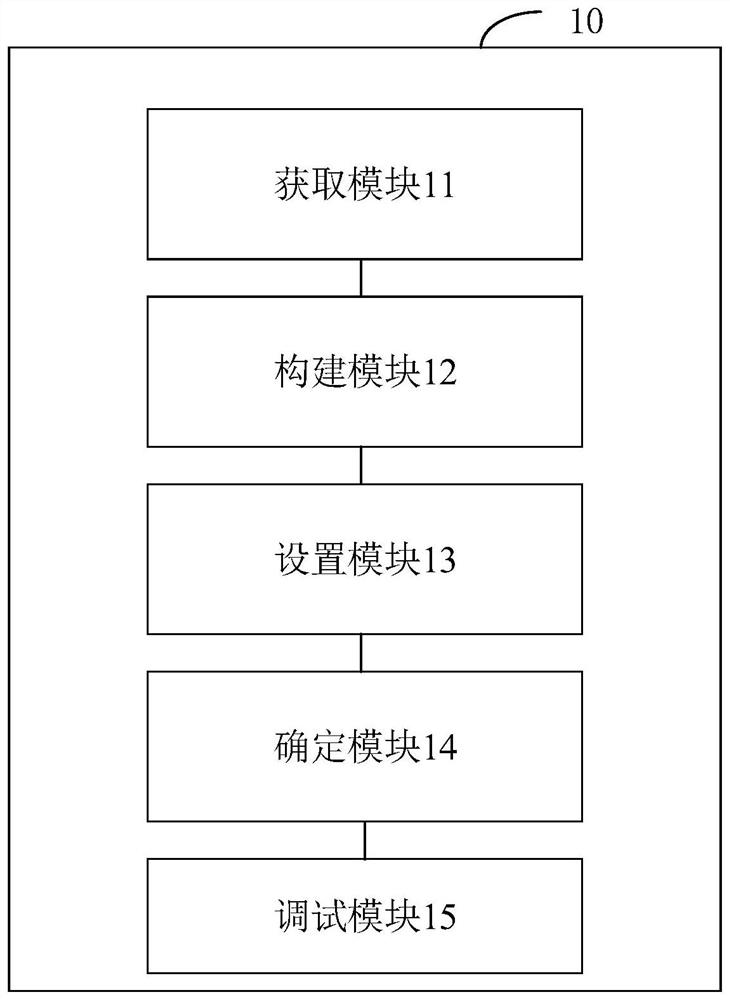

[0076] See image 3 , another embodiment of the present application proposes a steering gear virtual debugging device 10 , which includes: an acquisition module 11 , a construction module 12 , a setting module 13 , a determination module 14 and a debugging module 15 .

[0077] The acquisition module 11 is used to obtain the size parameters of each part of the robot, the position parameters of each steering gear and the type parameters of each steering gear; the construction module 12 is used to construct the 3D virtual model of the robot according to the size parameters of the various parts; The setting module 13 is used to set each virtual steering gear on the 3D virtual model according to the position parameters of the steering gears and the type parameters of the steering gears; the determination module 14 is used to set the virtual steering gears according to the corresponding The steering gear type parameter determines the debugging parameters of the i-th virtual steering...

Embodiment 3

[0086] See Figure 4 , the third embodiment of the present application proposes a terminal device 100, including a memory 110 and a processor 120, the memory 110 stores a computer program, and the computer program executes the present application when running on the processor 120 The steering gear virtual debugging method described in the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com