Fermentation tank for brewing soy sauce

A technology for brewing soy sauce and fermenter, which is applied to specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, sterilization method, etc. It can solve the problem that impurities cannot be effectively removed and achieve convenient cleaning , Avoid collision, fast fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

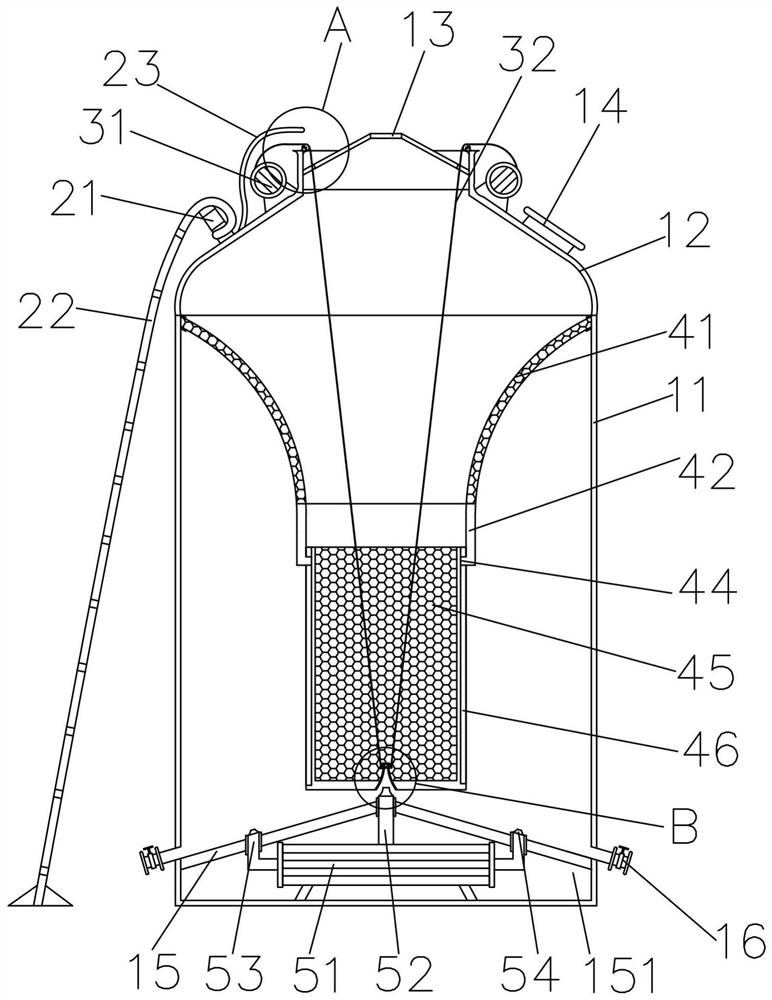

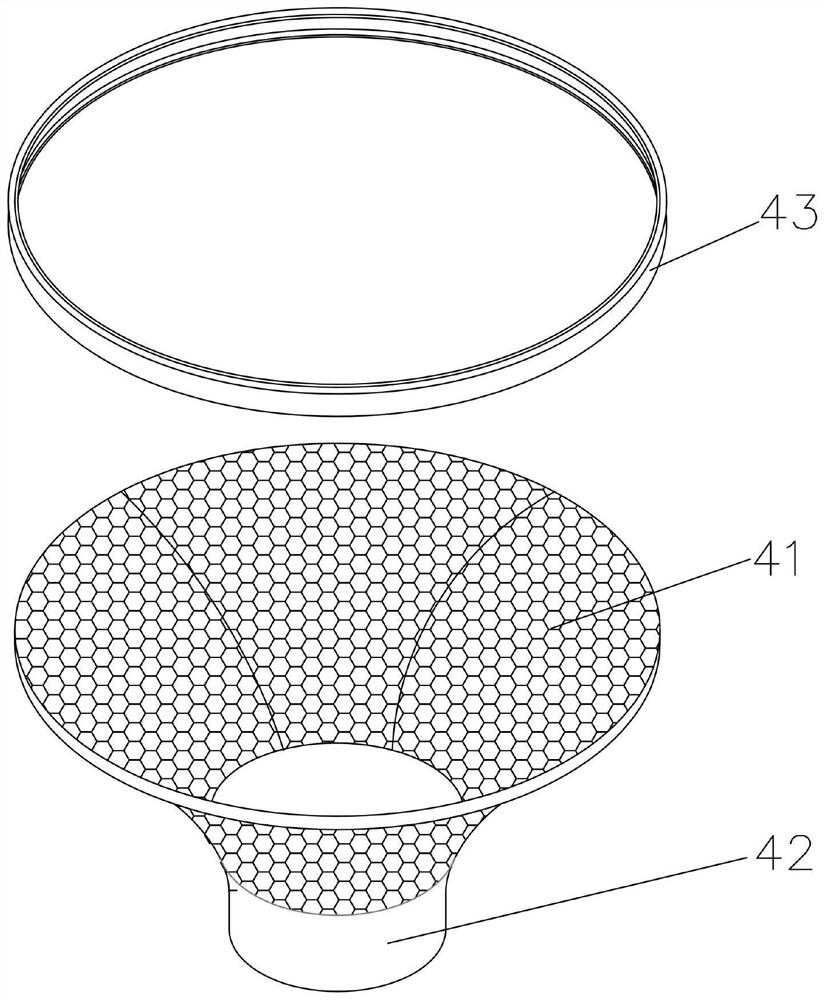

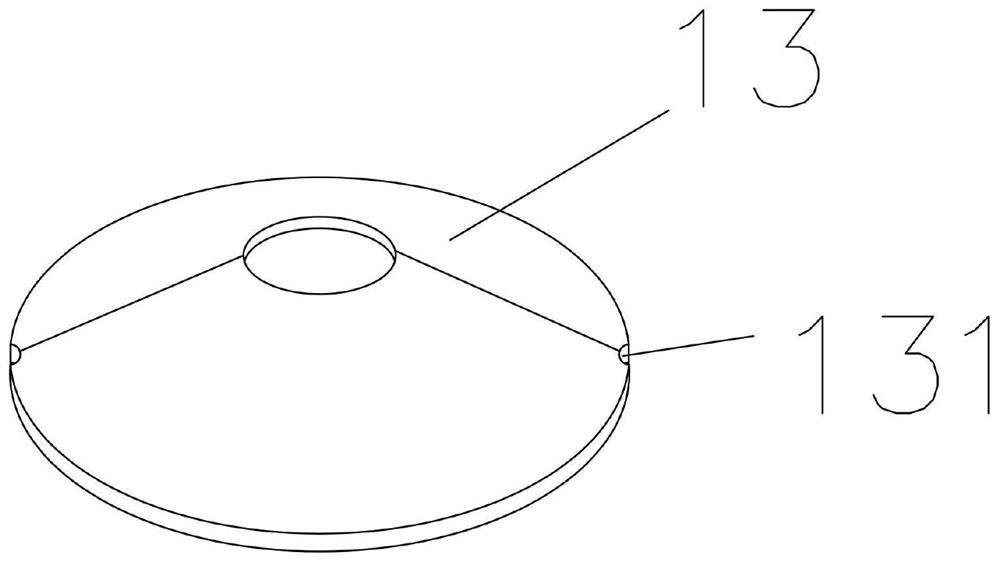

[0021] Embodiment: a kind of fermenter for brewing soy sauce, as Figure 1-Figure 6 As shown, the bottom tank body 11 and the top tank body 12 are included, the bottom tank body 11 and the top tank body 12 are plugged into each other, the top of the top tank body 12 is transparently set, and the left and right sides of the sealing cover 13 are provided for lifting. The side channel 131 connected by the mechanism, the opening of the top tank body 12 is sleeved with a sealing cover 13, one side of the top tank body 12 is provided with a feed port 14, and the top of the top tank body 12 is opposite to the feed port 14- The side is provided with a climbing structure, and the top of the top tank body 12 is provided with a lifting mechanism on the left and right sides of the opening. The bottom of the lifting mechanism extends to the inside of the bottom tank body 11. The top of the hopper 45 is provided with a leak-proof net cover 41, the top of the leak-proof net cover 41 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com