Sample edge oxidizing and trimming mechanism for food detection

A food detection and sample technology, applied in the field of sample edge oxidation and trimming mechanism for food detection, can solve the problems of being unsuitable for use in a detection room, troublesome to clean up, and high production cost, and achieve a good use effect, convenient cleaning and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

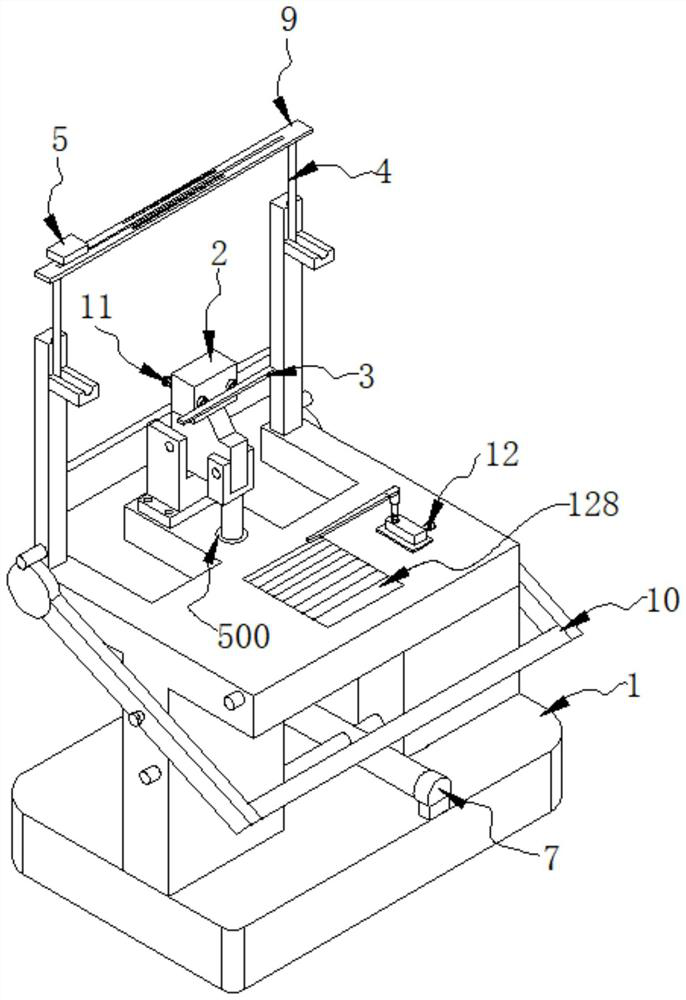

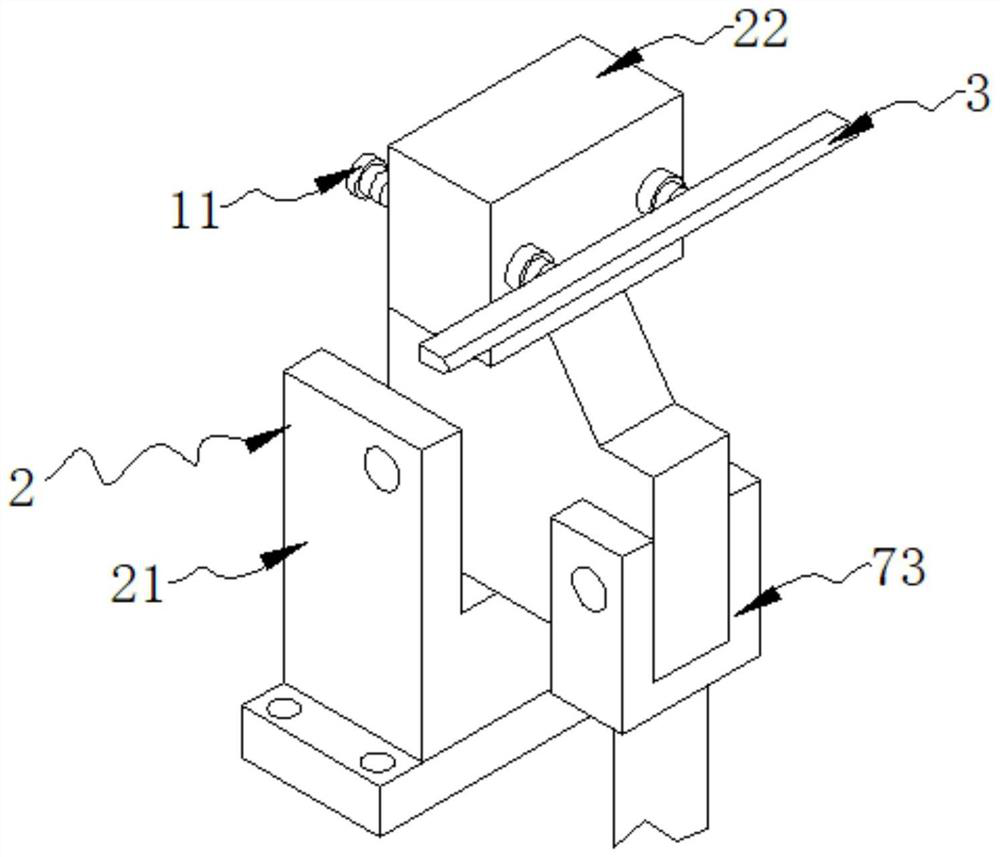

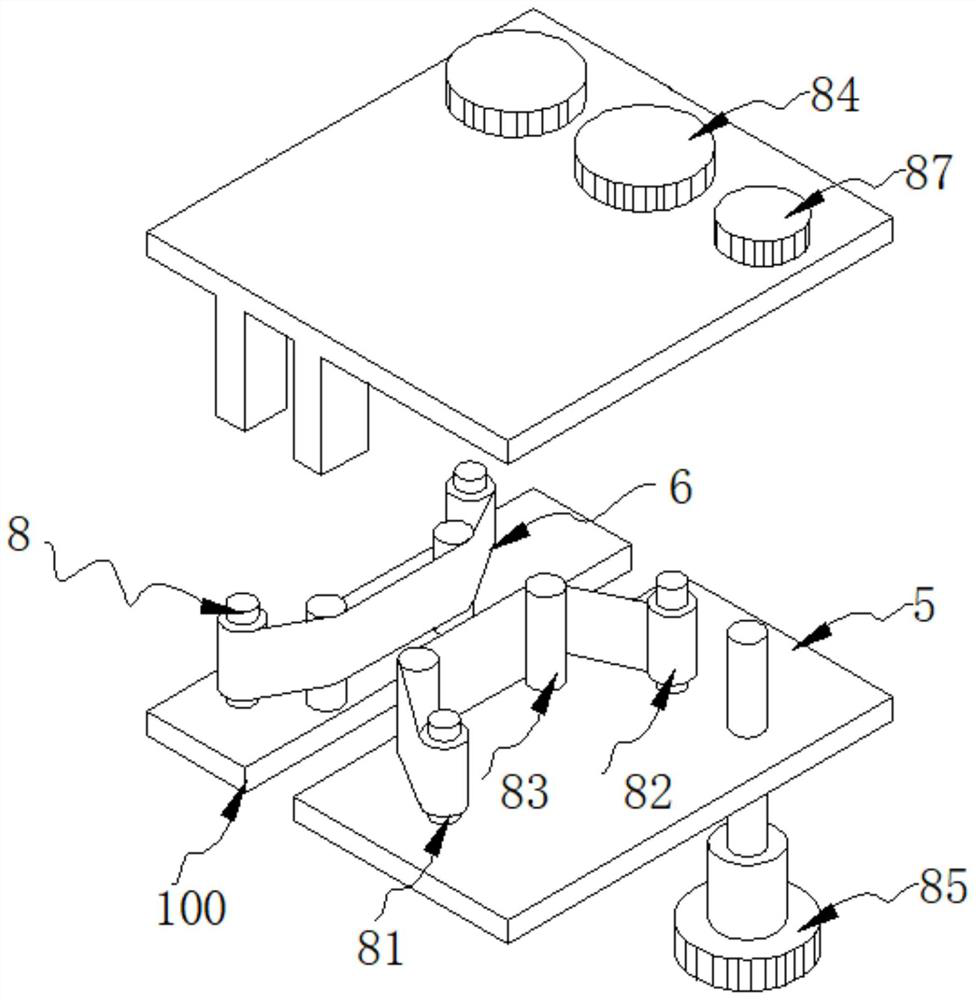

[0053] see Figure 1-Figure 13 ;

[0054] At present, most of the existing edge trimming devices are automatic devices with high production costs and are not suitable for use in the testing room. At the same time, since the cutter 3 is inside the machine, it is troublesome to clean up. To solve this problem, a A food testing sample edge oxidation trimming mechanism.

[0055] further:

[0056] Combining the above content: a sample edge oxidation trimming mechanism for food testing, including a fixed base 1, a steering device 2 fastened to the top bolt of the fixed base 1, and a cutter 3 is clamped and fixed on the steering device 2, and the outer side of the steering device 2 The rotating rod frame 4 is rotatably connected, and the cleaning box 5 is slidably connected to the rotating rod frame 4. The cleaning box 5 has a built-in cleaning part 6. The fixed base 1 is rotatably connected with a traction device 7, and one end of the traction device 7 penetrates the fixed base. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com