Rotating machinery small sample fault diagnosis method based on generative adversarial network

A technology for rotating machinery and fault diagnosis, applied in biological neural network models, neural learning methods, testing of mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

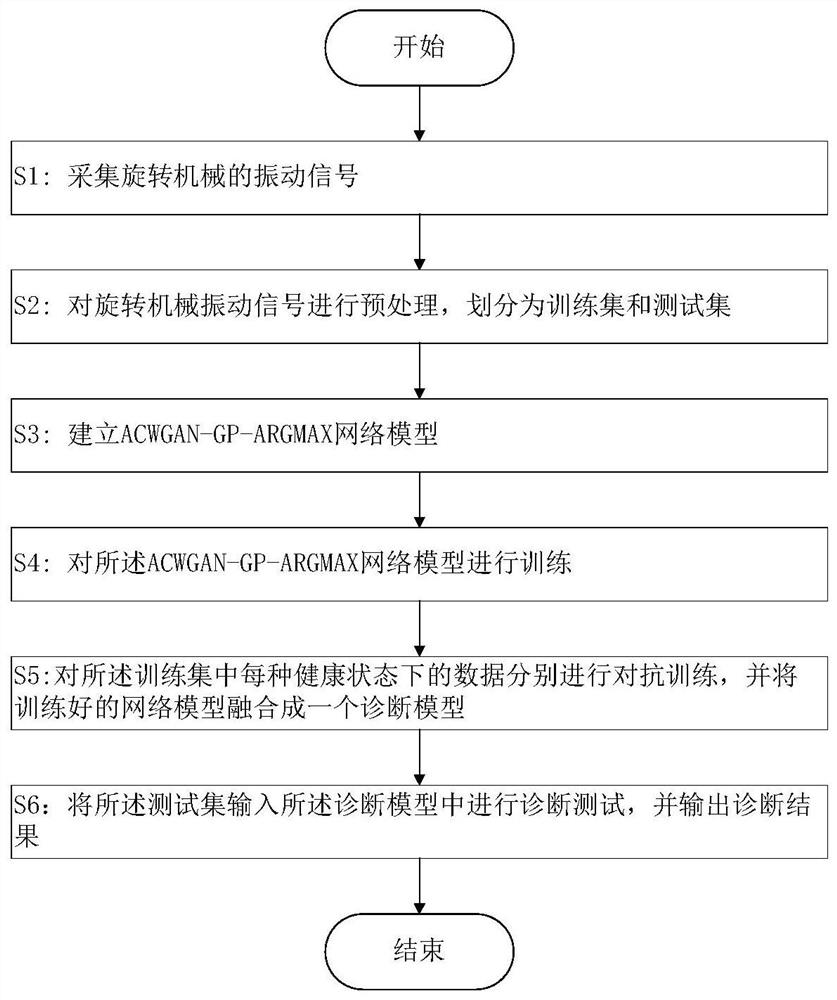

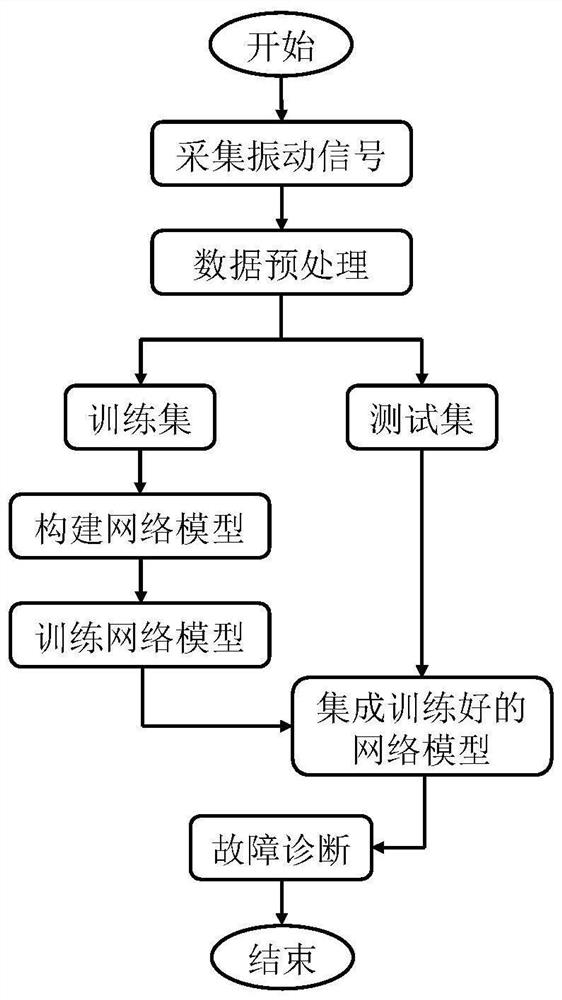

[0064] figure 2 It is an implementation flowchart of an embodiment of the small-sample fault diagnosis method of rotating machinery based on generative confrontation network in the present invention. Such as figure 2 As shown, the present invention is based on the specific steps of the rotating machinery small sample fault diagnosis method of generation confrontation network comprising:

[0065] S1: Use the vibration acceleration sensor to collect the vibration signal of the rotating machinery.

[0066] S2: Carry out data preprocessing on the collected vibration signals of rotating machinery, construct an original data set, and divide the original data set into a training set and a test set.

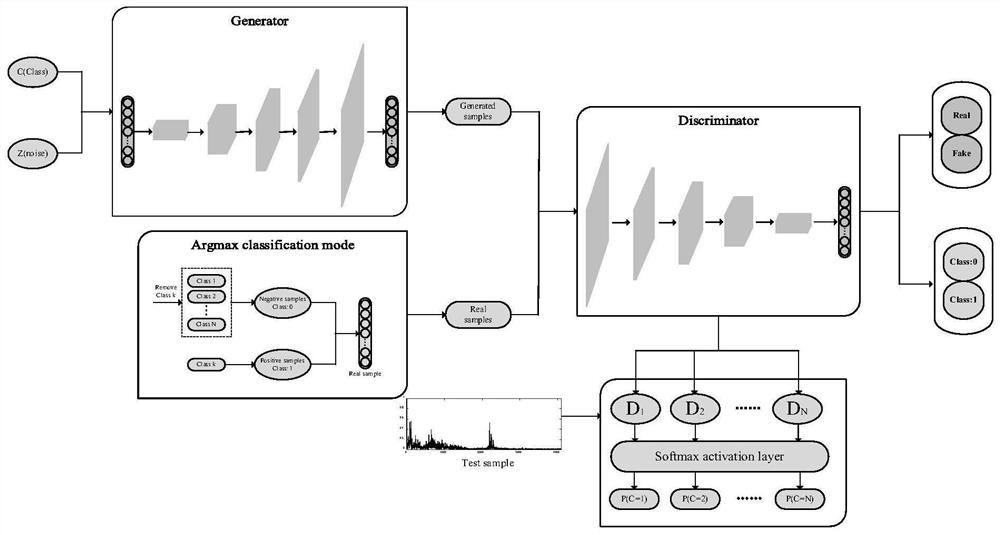

[0067] S3: Build a network model based on ACWGAN-GP-ARGMAX.

[0068] S4: Carry out model training on the ACWGAN-GP-ARGMAX-based network model, and integrate the trained network model in each health state to construct a diagnostic model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com