Caliper brake

A technology of caliper brakes and braking surfaces, applied in the direction of brakes, brake types, axial brakes, etc., can solve the problems of disc and friction pad friction dragging, pistons cannot return smoothly, and pedal feeling is reduced, so as to improve fuel consumption. Efficiency, shortened assembly process time, and improved fallback performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] best practice

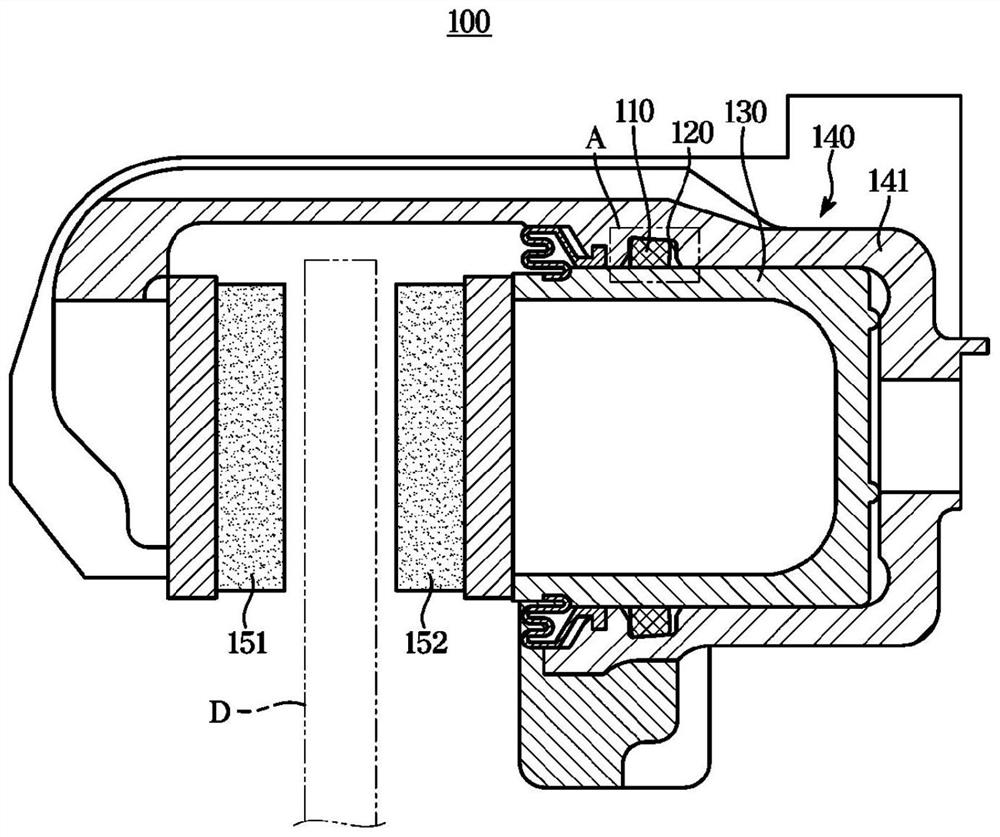

[0039] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following embodiments are proposed in order to fully convey the idea of the present invention to those of ordinary skill in the art to which the present invention pertains. The present invention is not limited to the embodiments presented here, and may be embodied in other forms. In order to clearly describe the present invention, illustration of parts irrelevant to the description is omitted, and the size of components may be slightly exaggerated to facilitate understanding.

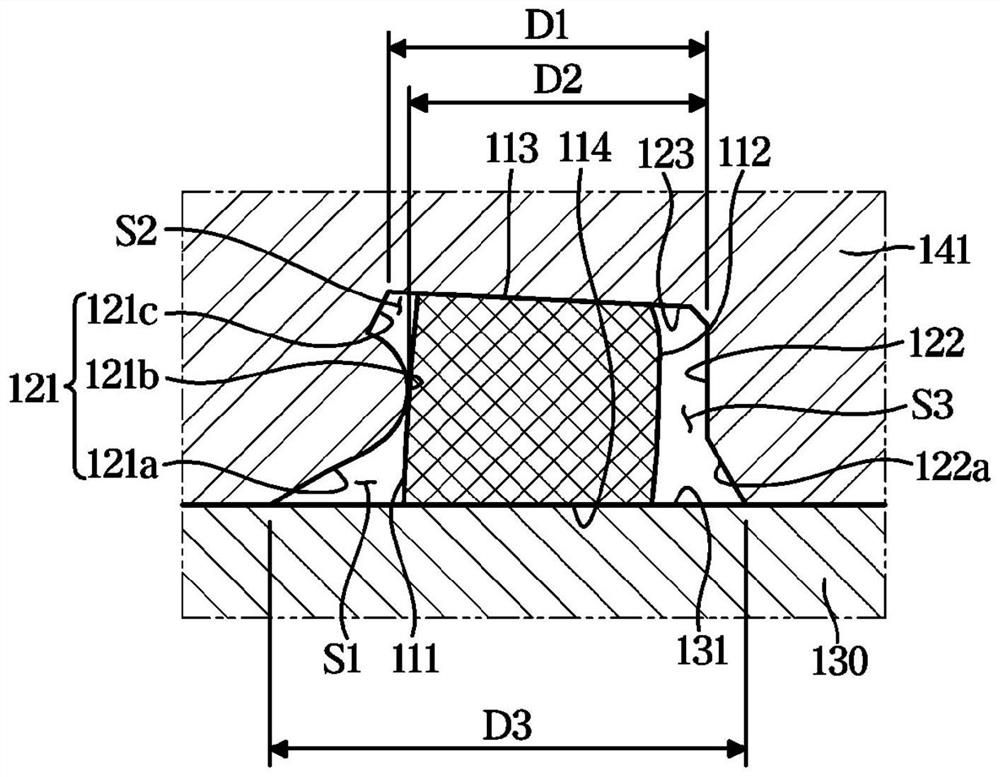

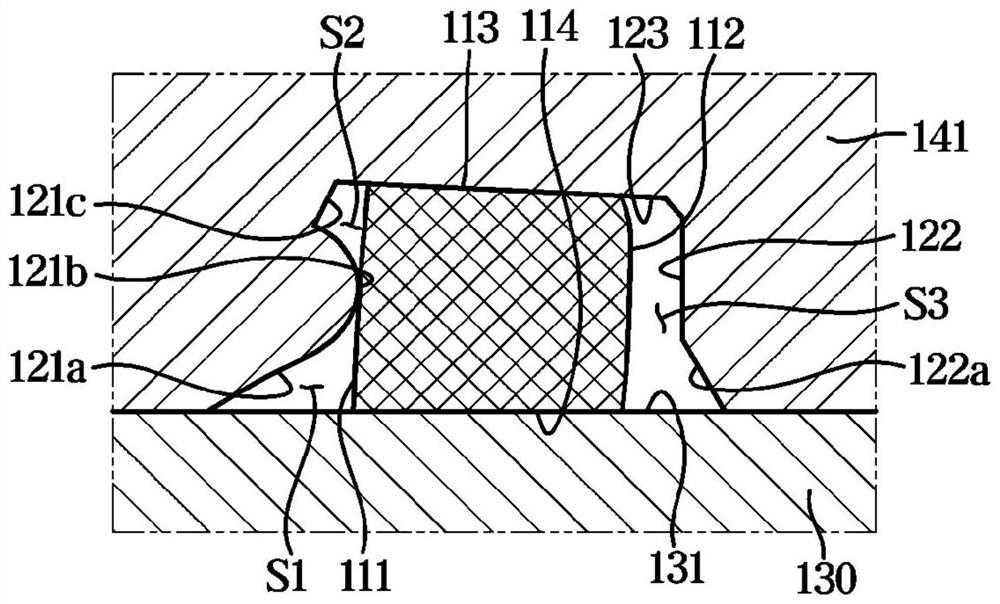

[0040] The sealing member 110 of a conventional caliper brake is configured as a ring shape in which the outer peripheral surface 113 is in close contact with the inner surface of the cylinder 141 and the inner peripheral surface 114 is in tight contact with the outer surface of the piston 130 . At this time, the cross section of the sealing member 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com