Sole and shoe

The invention relates to a technology of shoe soles and shoe soles, which is applied to shoe soles and shoes. field, it can solve the problems of high operating frequency of the one-way valve, failure of the dust one-way valve, easy aging, etc., and achieve the effect of good exhaust effect, uniform exhaust effect and increased comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

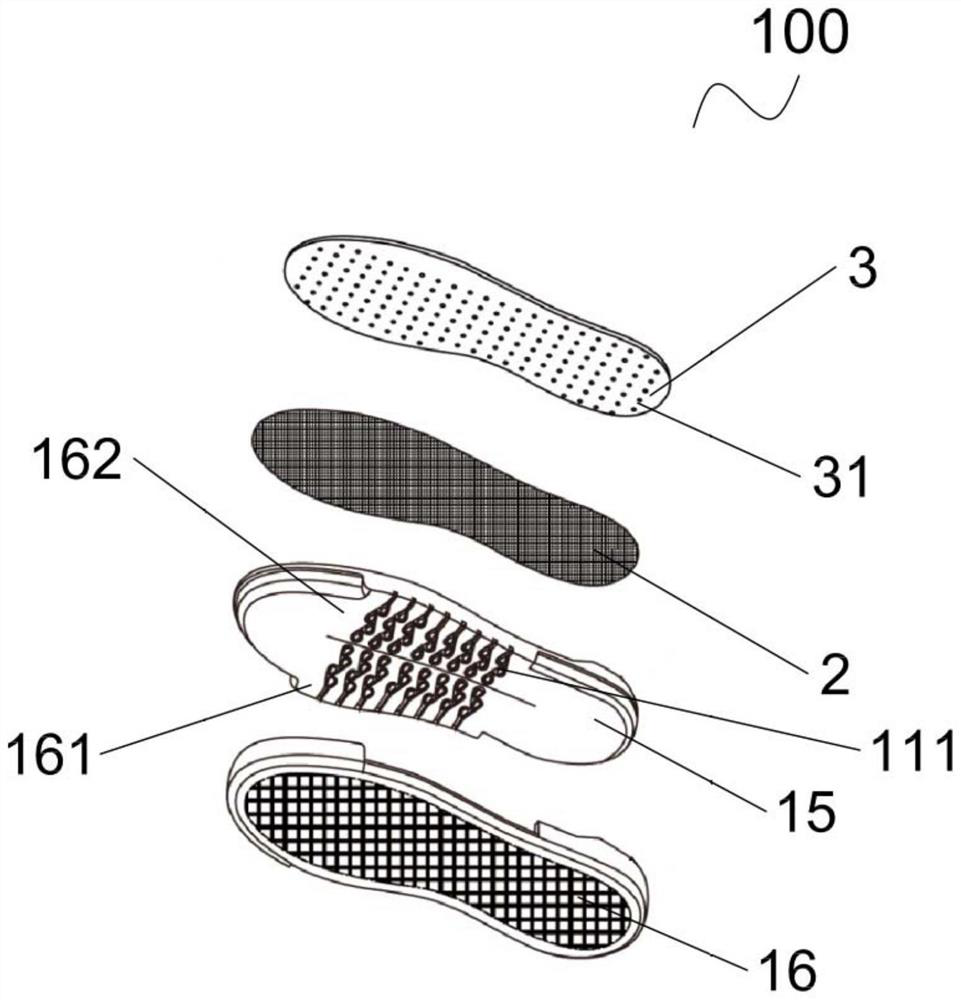

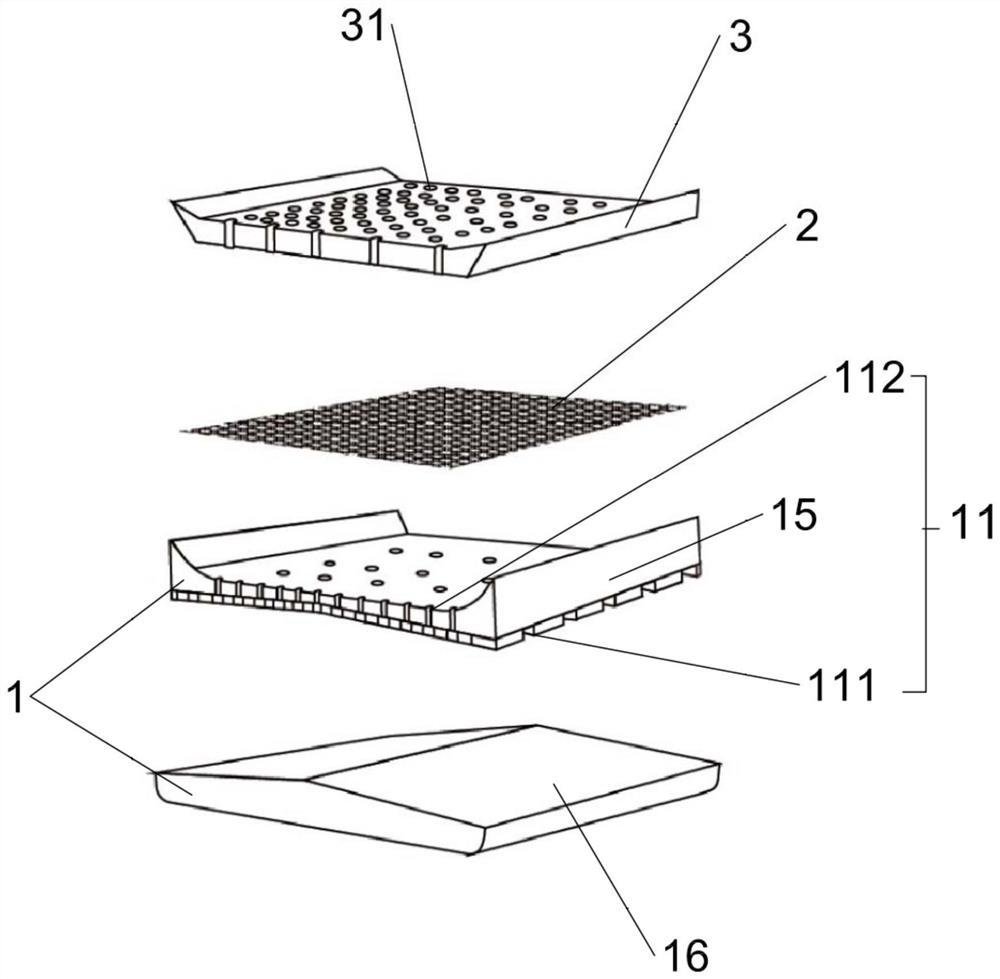

[0044] see figure 1 , figure 1 It shows that the sole 100 includes a sole body 1 , a waterproof breathable cloth 2 and an insole 3 .

[0045] Such asfigure 1 and figure 2 As shown, the sole body 1 is provided with an exhaust channel 11 , and the exhaust channel 11 includes a one-way channel 111 and several air intake channels 112 . Wherein, the one-way passage 111 is a Tesla valve structure, and its first end extends to the side wall of the sole body 1, and is provided with an exhaust port opening on the side wall of the sole body 1; The direction is the conduction direction. Each air inlet 112 is arranged along the conduction direction of the one-way channel 111 , and one end is opened on the upper surface of the sole body 1 , and the other end communicates with the one-way channel 111 .

[0046] In this example, if figure 1 and figure 2 As shown, the sole body 1 is provided with a first group of exhaust passages 11 and a group of second exhaust passages 11 , and each...

Embodiment 2

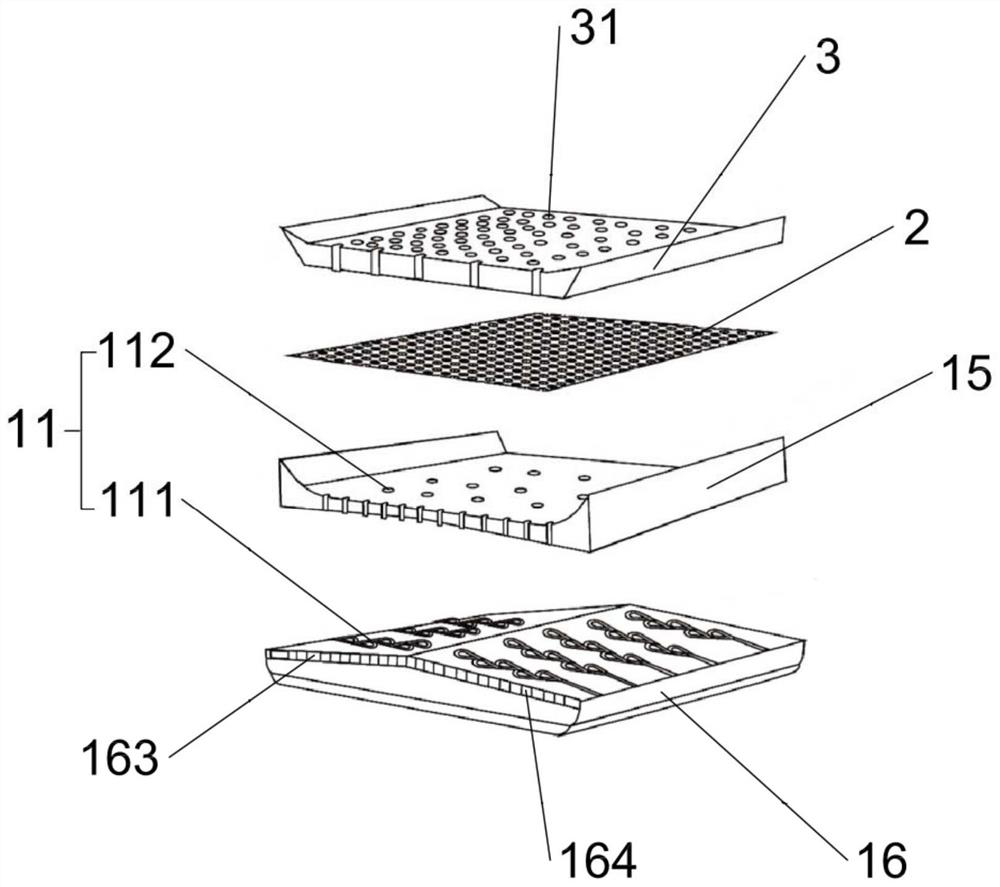

[0056] Such as figure 1 , figure 2 and 3 As shown, the difference between the present embodiment and the first embodiment lies in the structure of the sole body 1 and the setting position of the exhaust channel 11 . In this embodiment, the sole body 1 includes an upper sole 15 and a lower sole 16 fixedly connected to each other.

[0057] Among them, such as image 3 As shown, each air inlet 112 is provided on the upper bottom 15 , and the air inlet 112 vertically penetrates the upper surface and the lower surface of the upper bottom 15 .

[0058] Such as image 3 As shown, the top of the lower bottom 16 is provided with a third inclined wall 163 and a fourth inclined wall 164 that slope downward from the middle, and the sides of the third inclined wall 163 and the fourth inclined wall 164 at the middle of the top of the lower bottom 16 coincide. The one-way channels 111 of the first group of exhaust channels 11 are arranged on the third inclined wall 163 , and the one-wa...

Embodiment 3

[0061] Such as figure 1 , figure 2 and Figure 4 As shown, the difference between the present embodiment and the first embodiment lies in the structure of the sole body 1 and the setting position of the exhaust channel 11 . In this embodiment, the shoe sole body 1 includes an exhaust module 17 , an upper bottom 15 and a lower bottom 16 that are fixed as one.

[0062] Among them, such as Figure 4 As shown, the top of the exhaust module 17 is provided with a fifth inclined wall 171 and a sixth inclined wall 172 inclined downward from the middle; Edges coincide. The one-way passages 111 in the first exhaust passage 11 are arranged on the fifth inclined wall 171 ; the one-way passages 111 in the second exhaust passage 11 are arranged on the sixth inclined wall 172 . Each one-way passage 111 of the first exhaust passage 11 group and each one-way passage 111 of the second exhaust passage 11 group are respectively arranged on the fifth inclined wall 171 and the sixth inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com