long range sprayer

A sprayer and long-range technology, which is applied in the direction of spraying devices, etc., can solve the problems of increased volume of the fog cannon mechanism, occupation of the fog cannon mechanism, unfavorable handling and vehicle transportation, etc., and achieve piston impact force change, less space, and small kinetic energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

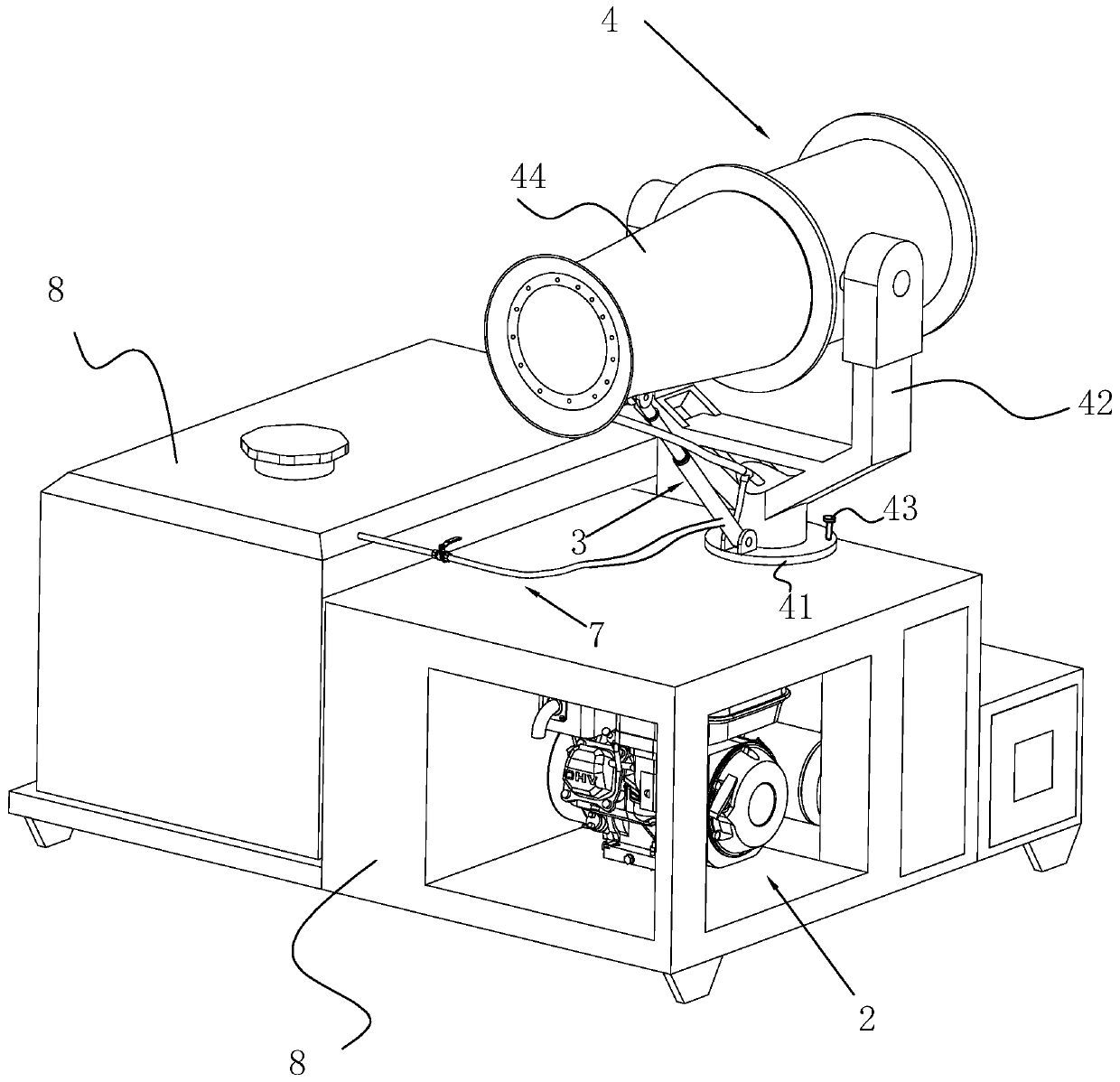

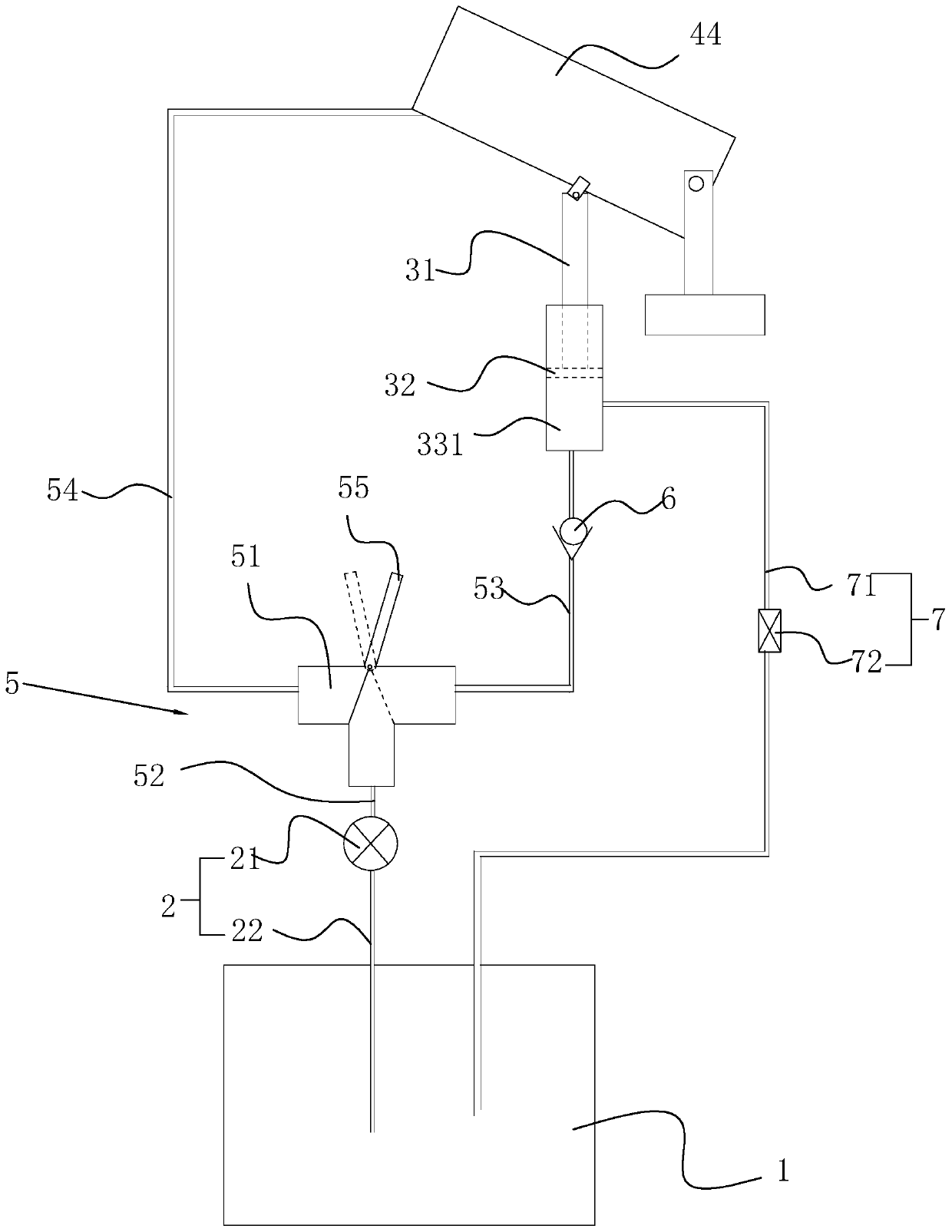

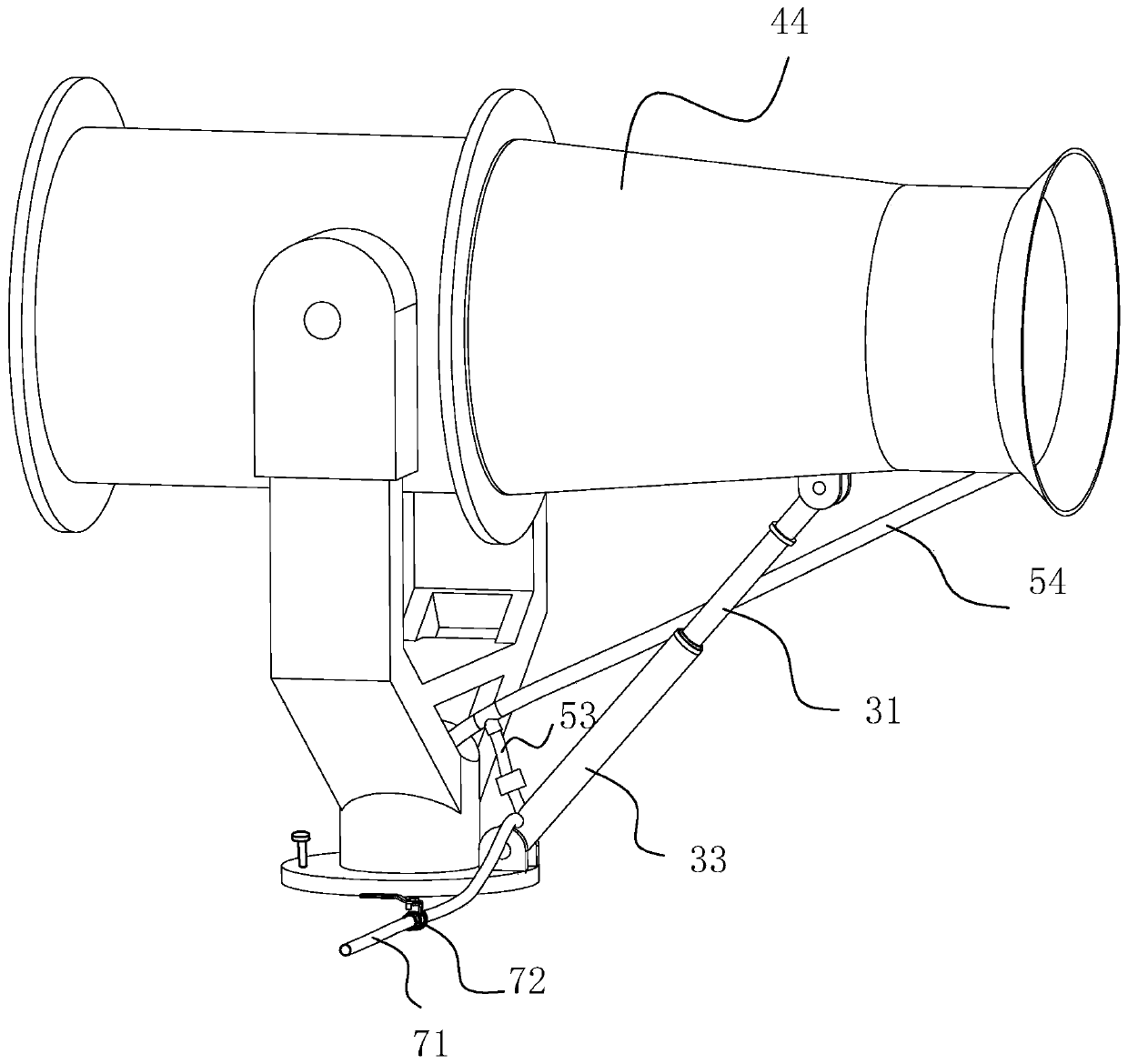

[0048] A long range sprayer such as figure 1 and figure 2As shown, it includes a frame body 8, and the frame body 8 is provided with a liquid tank 1, a liquid pumping assembly 2, a spray assembly 4, and a hydraulic assembly 3 that pushes the spray assembly 4 to lie supine on a vertical plane. The liquid pumping assembly 2 provides water or liquid medicine to either the hydraulic assembly 3 or the spray assembly 4 , and the flow of water in the liquid pumping assembly 2 is controlled by the valve group 5 . The liquid inlet of the hydraulic component 3 is provided with a valve, which maintains the pressure of the hydraulic component 3 and prevents the water in the hydraulic component 3 from flowing back into the pumping component 2 . The hydraulic component 3 is provided with a pressure relief component 7, which is usually sealed. When the liquid in the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com