Protective device capable of automatically rising and falling during welding operation

A protective device and automatic technology, applied in ophthalmic surgery, goggles, etc., can solve the problems of easy fatigue of the arm holding the protective mask, heavy weight of the hand-held mask, etc., and achieve the effect of reducing labor intensity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-4 The application is described in further detail.

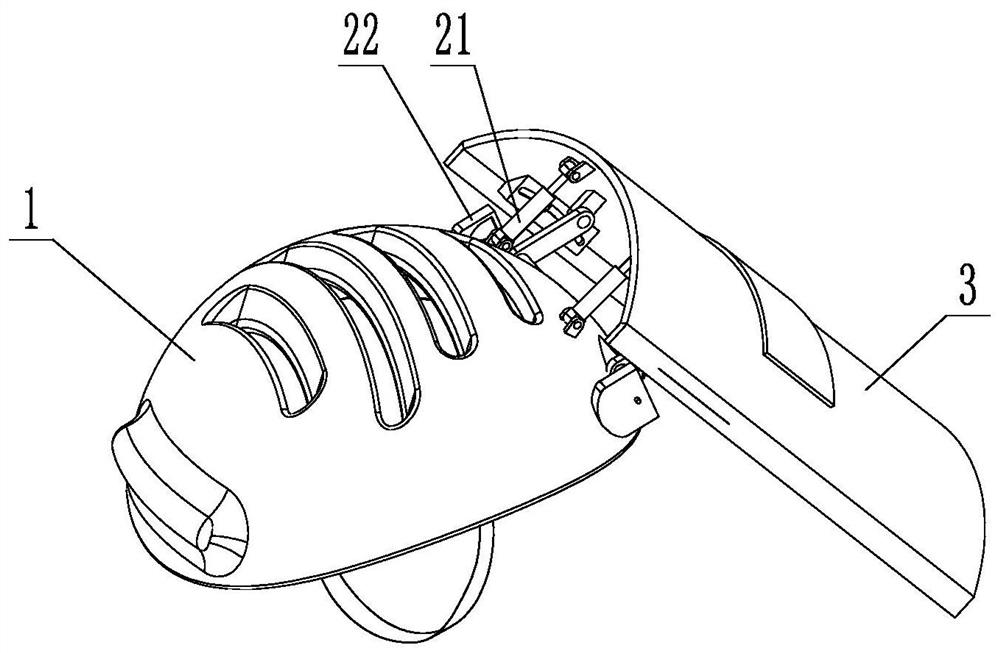

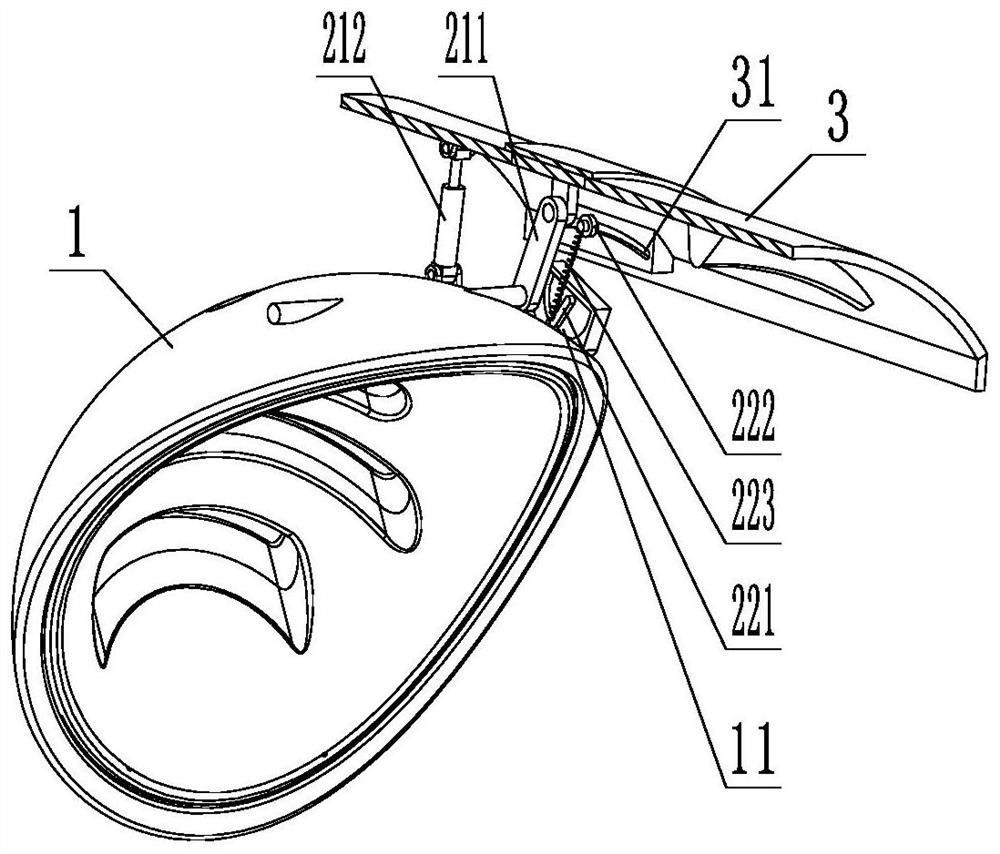

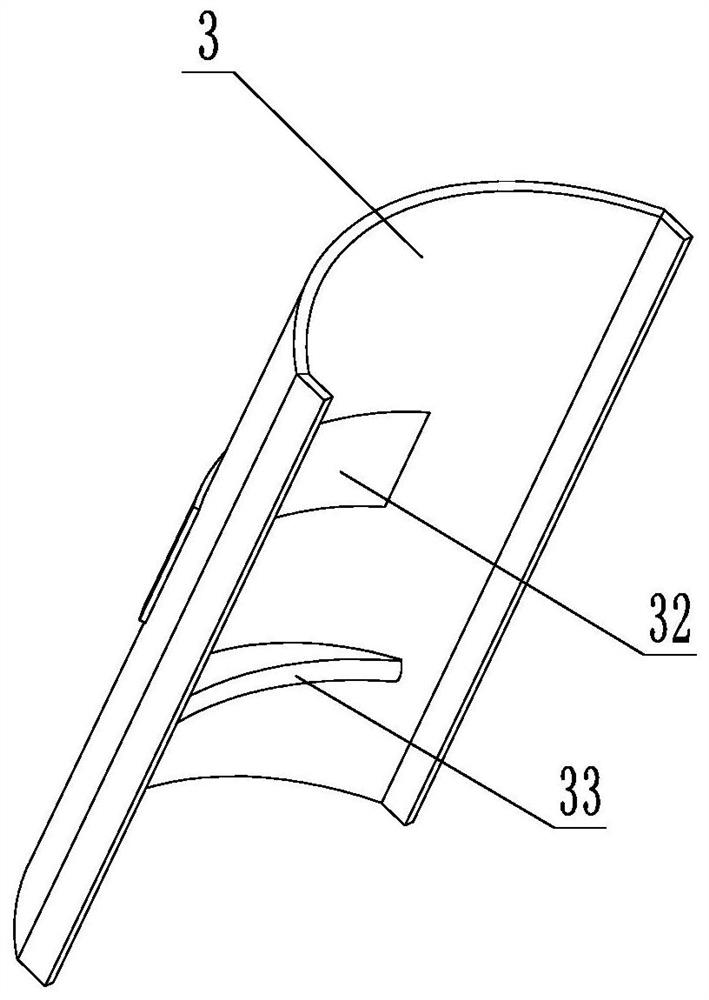

[0034] The embodiment of the present application discloses a protection device that automatically rises and falls during welding operations. refer to figure 1 , a protective device that automatically rises and falls during welding operations includes a helmet 1, a control mechanism 2 mounted on the helmet 1 and a protective cover 3 mounted on the control mechanism 2. The worker puts the helmet 1 on the head before the welding operation, and then uses the control mechanism 2 to control the position of the protective cover 3, and moves the protective cover 3 to the lowest position. At this time, the protective cover 3 covers the face of the worker to avoid working Personnel's eyes were injured by the intense light from the welding.

[0035] refer to figure 1 , the control mechanism 2 includes a mounting frame 21 and a driving assembly 22 installed on the helmet 1, the mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com