Gradient injection containing mixed polymer microspheres

A technology of mixing polymers and injections, which is applied in the field of medical cosmetic materials, can solve the problems of short duration of effect and difficulty in achieving excellent effects, and achieve the effects of reducing usage, avoiding nodules, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

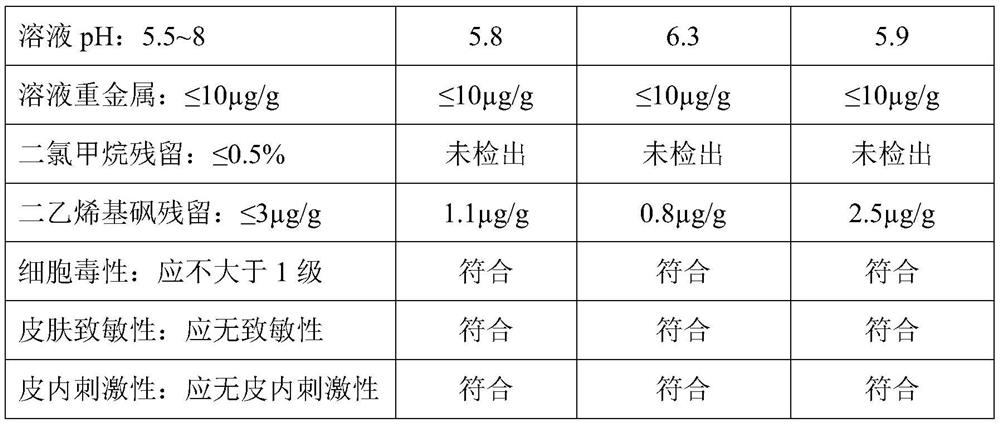

Examples

Embodiment 1

[0030] (1) Preparation of PLLA microspheres: Dissolve 6g PLLA (average molecular weight 156kDa) in 114g methylene chloride to make a polymer solution with a mass concentration of 5%, i.e. oil phase 1; weigh 10g Tween 20 in 490g water , stirred and dissolved to prepare an aqueous solution with a mass concentration of 2%, that is, the water phase 1; add all the oil phase 1 into the water phase 1, stir and emulsify for 30 minutes, and obtain an oil-in-water emulsion; keep stirring the emulsion at 30°C for 12 hours to make Dichloromethane was completely volatilized, and centrifuged to obtain PLLA microspheres; washed with water and ethanol respectively, and vacuum-dried to obtain 5.6 g of powdery solid PLLA microspheres; the microspheres were sieved with 63 μm and 20 μm sieves respectively to obtain 20-63 μm PLLA microspheres. PLLA microspheres 4.1 g.

[0031](2) Preparation of cross-linked sodium hyaluronate microspheres: 6 g of sodium hyaluronate powder (average molecular weight...

Embodiment 2

[0034] (1) Preparation of PLLA microspheres: prepare 0.5% PLLA (average molecular weight 260kDa) methylene chloride oil phase solution 300g by the same method as in Example 1; reconfigure 5% Tween 60 water phase solution 2000g; two-phase mixing and stirring 10min, then continued to stir at 40°C for 12h to completely volatilize the dichloromethane, centrifuged to obtain PLLA microspheres, washed and vacuum-dried to obtain 1.4g of PLLA microspheres; sieved the microspheres with 85μm and 40μm sieves respectively to obtain 0.9 g of PLLA microspheres of 40-85 μm.

[0035] (2) Preparation of cross-linked sodium hyaluronate microspheres: prepare 100 g of 5% (average molecular weight 1750 kDa) sodium hyaluronate aqueous phase solution by the same method as in Example 1; then configure 5% Span 80 liquid paraffin oil phase 600 g of solution; the two phases were mixed and stirred for 5 min, and 0.2% divinyl sulfone relative to the mass of sodium hyaluronate powder was added to the emulsi...

Embodiment 3

[0038] (1) Preparation of PLLA microspheres: prepare 12% PLLA (average molecular weight 52kDa) oil phase solution 50g by the same method as in Example 1; reconfigure 1250g of aqueous phase solution of 0.5% sodium lauryl sulfate; Two-phase mixing and stirring 120min, then continued to stir at 25°C for 12h to completely volatilize the dichloromethane, centrifuged to obtain PLLA microspheres, washed and vacuum-dried to obtain 5.8g of PLLA microspheres; sieved the microspheres with 25μm and 3μm sieves respectively to obtain 3.2 g of PLLA microspheres of 3-25 μm.

[0039] (2) Preparation of cross-linked sodium hyaluronate microspheres: prepare 10 g of 30% (average molecular weight 130 kDa) sodium hyaluronate aqueous phase solution by the same method as in Example 1; 80 g of liquid paraffin oil phase solution in a plate; the two phases were mixed and stirred for 100 min, and 10% divinyl sulfone relative to the mass of sodium hyaluronate powder was added to the emulsion, and stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap