Fabric gripping device

A technology for grabbing devices and fabrics, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as low production efficiency, time-consuming and laborious, and failed handling, and achieve the effects of low cost, firm gripping of fabrics, and ingenious and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

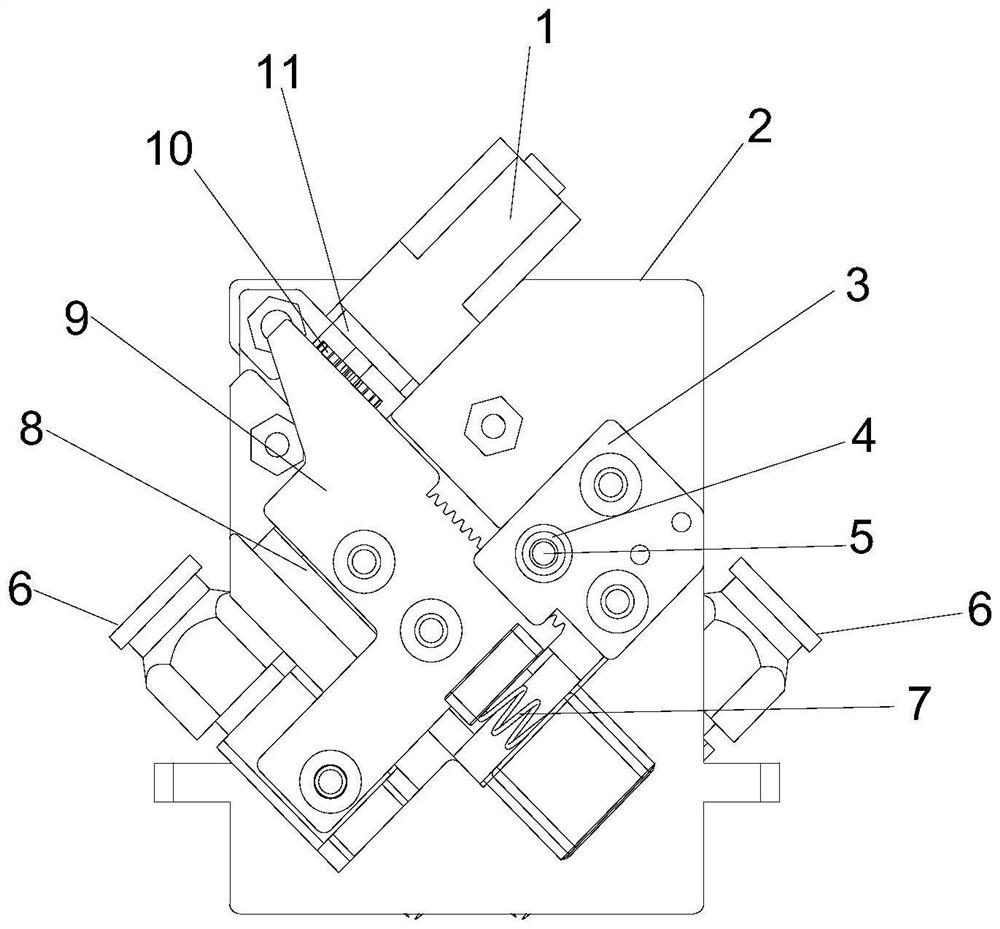

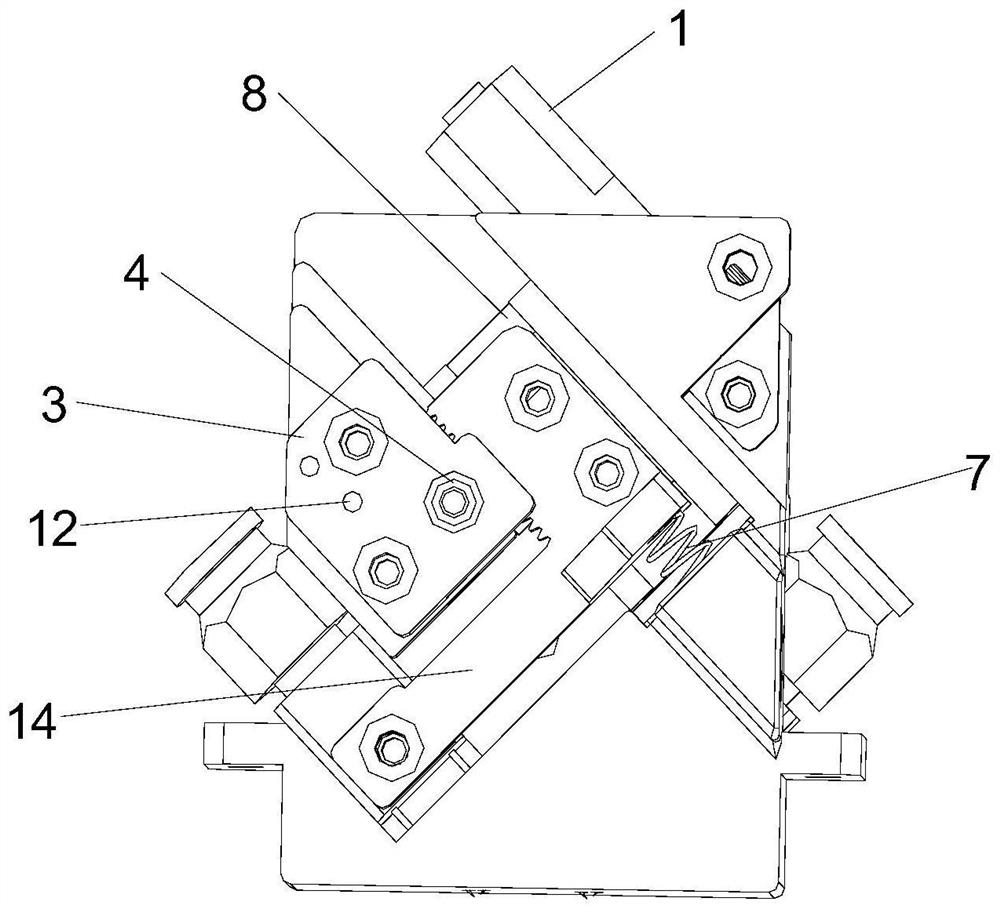

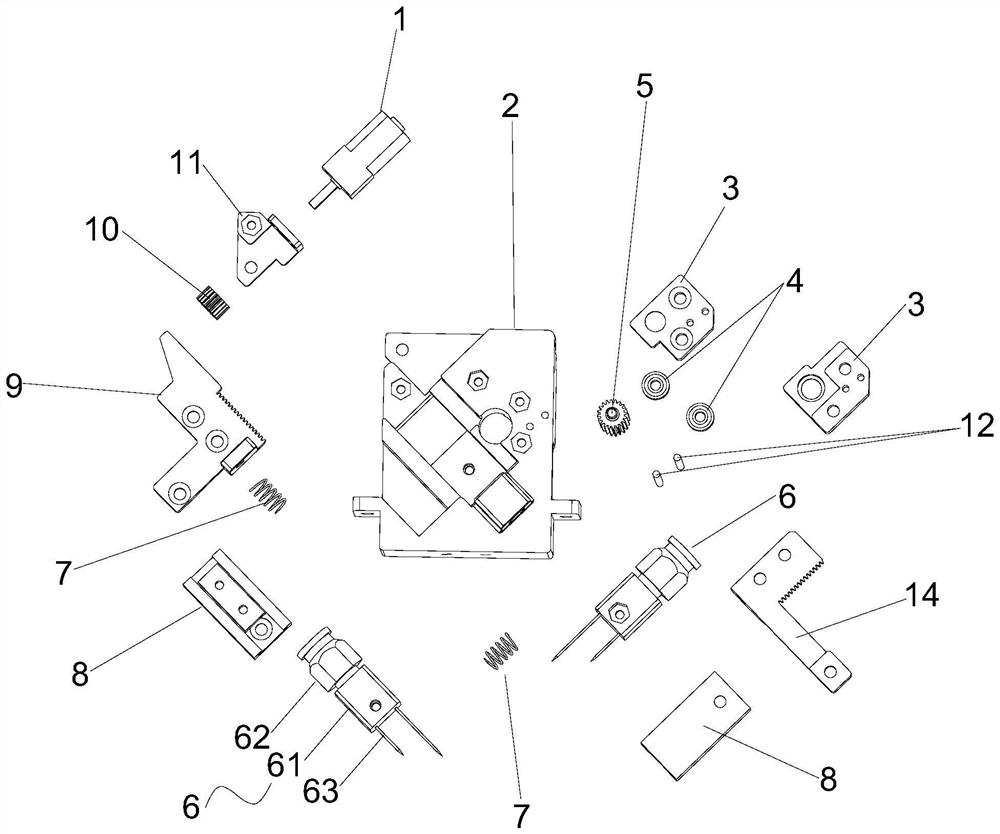

[0032] like Figure 1~4 As shown, the fabric grabbing device of this embodiment includes a fixed seat 2 and a motor 1 located on the fixed seat 2, a gear transmission unit, and two groups of grabbing mechanisms 6;

[0033] Described motor 1 is fixed on the fixed seat 2 by motor fixing plate 11, and the rotating shaft of described motor 1 is provided with rotating gear 10; In the present embodiment, the driving unit adopts motor, and in other embodiments, electromagnet, Driven by electric or pneumatic cylinders;

[0034] The two groups of grasping mechanisms 6 are arranged vertically and intersecting;

[0035] The gear transmission unit includes a first rack 9, a second rack 14 and a reversing gear 5, the first rack 9 is connected with one group of grabbing mechanisms 6, and the second rack 14 is connected with another group The gripping mechanism 6 is connected; the first rack 9 includes a lower rack arranged downward and a side rack arranged sideways, and the rotating gear ...

Embodiment 2

[0049] like Figure 5-8 As shown, the main structure of the fabric grabbing device of this embodiment is similar to that of Embodiment 1, the difference mainly lies in the design of the grabbing mechanism 6 .

[0050] In this embodiment, the gripping mechanism 6 includes a connecting piece 61 and a splint 64, the connecting piece 61 is connected with the first rack 9 or the second rack 14 of the gear transmission unit; 64 front cross contacts to grip the fabric. In this embodiment, each group of gripping mechanisms 6 is provided with two groups of splints 64 with different lengths, and the front ends of the splints 64 are on the same horizontal plane. Since the splint 64 has a certain cross section, the clamping of the fabric is more firm.

[0051] The installation method of the fabric grabbing device in this embodiment is similar to that in Embodiment 1.

[0052] The working principle of the fabric grabbing device of this embodiment is as follows:

[0053] The motor 1 wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com