Corrugated carton flattening assembly

A technology for corrugated boxes and components, applied in the field of corrugated boxes, can solve the problems of poor flattening effect and low efficiency, and achieve the effects of uniform flattening, high efficiency and improved flattening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

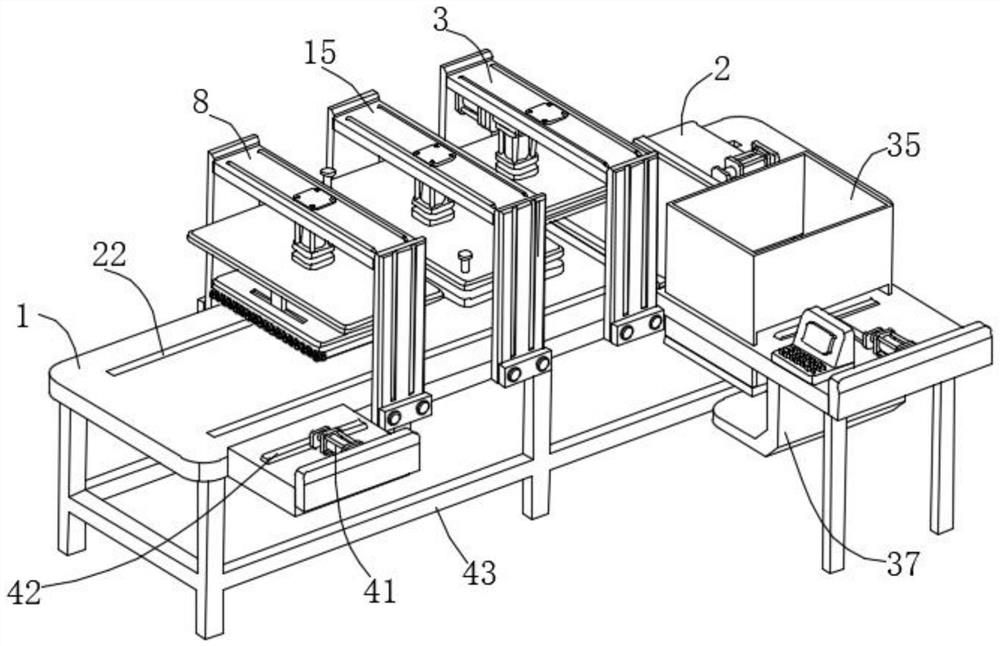

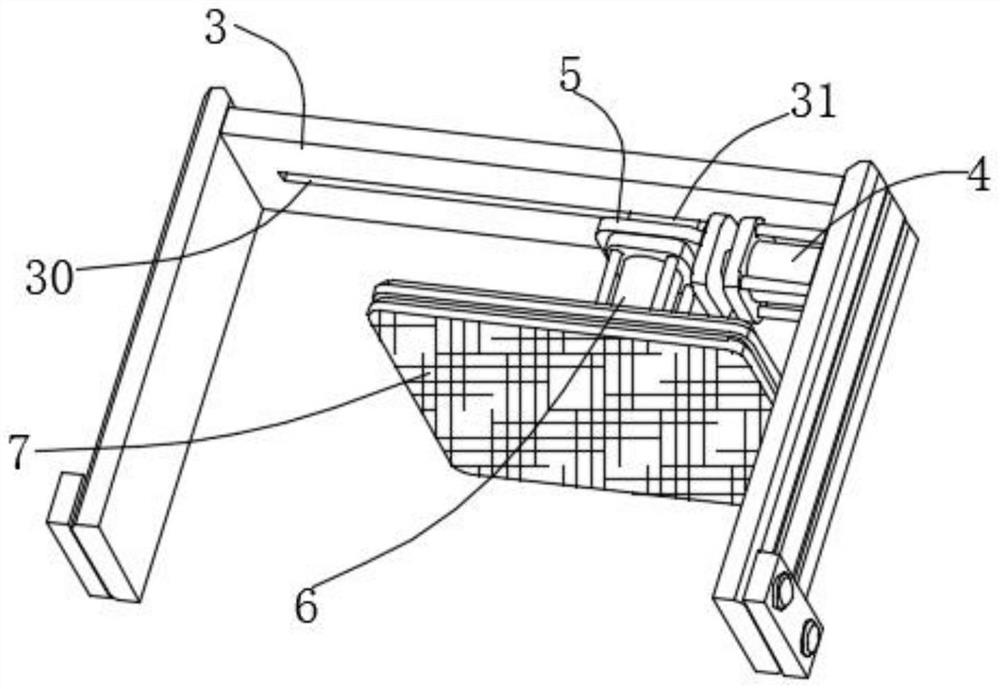

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, this embodiment proposes a corrugated box flattening assembly, including a horizontally arranged door-shaped table top 1, a console is installed on the upper surface of the table top 1, the console is used to control the electric components, and a base is fixedly installed on the lower end of the table top 1 frame 43, the upper end surface of the table top 1 is horizontally installed with a moving plate 2 through a sliding mechanism, the upper end surface of the moving plate 2 is equipped with a fixing mechanism, and one end of the outer side wall of the moving plate 2 is fixedly installed with a first fixed frame 3, and the inner side wall of the first fixed frame 3 passes through The first electric push rod 4 is laterally fixedly equipped with a connecting plate 5, and the connecting plate 5 is connected with the inner top surface of the first fixed frame ...

Embodiment 2

[0035] The scheme in embodiment 1 is further introduced below in conjunction with specific working methods, see the following description for details:

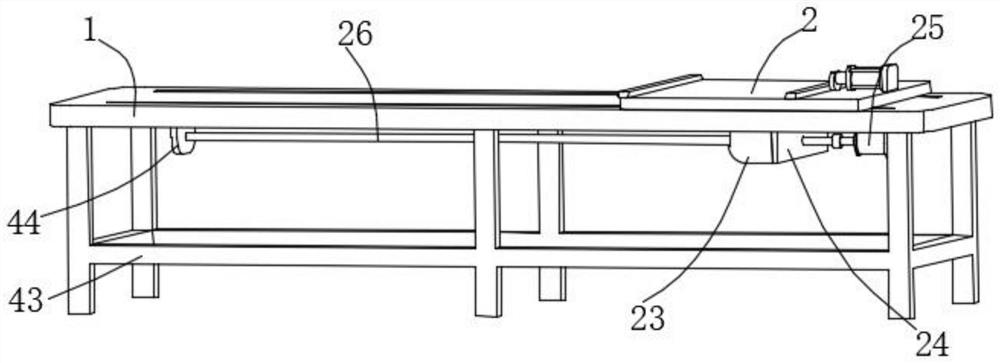

[0036] Such as figure 1 , figure 2 , Image 6 As shown, as a preferred embodiment, on the basis of the above-mentioned method, the sliding mechanism includes a moving groove 22 set horizontally on the upper end surface of the table top 1 and passing through the table top 1, and the lower end surface of the moving plate 2 is vertically fixedly installed with a sliding and penetrating moving groove 22 The moving block 23, the side wall of the moving block 23 is vertically fixedly installed with a power plate 24, and the lower end surface of the table top 1 is horizontally fixedly installed with a first motor 25, and the first motor 25 adopts a servo motor that can be reversible. The positive and negative rotation of the motor 25 indirectly drives the moving plate 2 to move. The output shaft of the first motor 25 is fixedly in...

Embodiment 3

[0038] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0039] Such as figure 1 , Figure 7 , Figure 8 As shown, as a preferred embodiment, on the basis of the above method, the feeding mechanism includes a fixed frame 35 that moves through the side walls on both sides of the table 1, and the fixed frame 35 penetrates the lower end surface of the side wall of the table 1. Lifting plate 36, the lower end surface of table top 1 is fixedly equipped with L-shaped support frame 37, and vertically fixedly installed on the upper end surface of support frame 37 is the lifting electric push rod 38 whose free end is fixedly connected with the lower end surface of lifting plate 36, and the fixed frame 35 moves away from One side of the plate 2 is horizontally provided with a feeding electric push rod 39 fixedly installed on the upper end of the table top 1, and the free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com