Flexible return capsule capable of avoiding hot melting of air bag

A return capsule and airbag technology, applied in the field of return capsule, can solve the problems of airbag thermal melting and air leakage, and achieve the effect of ensuring integrity, normal operation and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

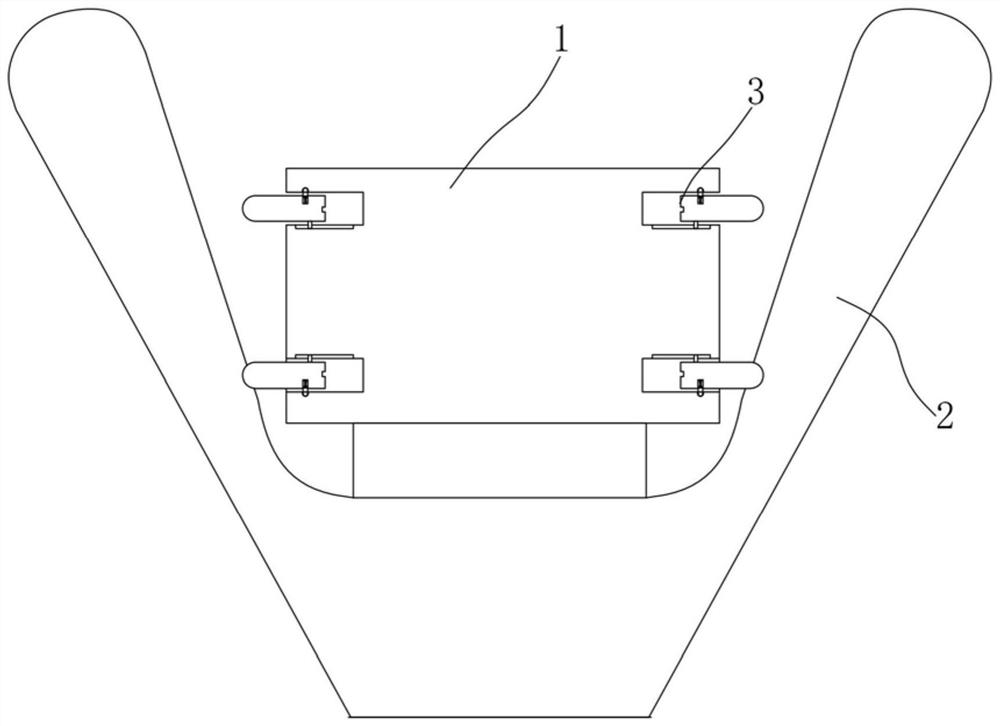

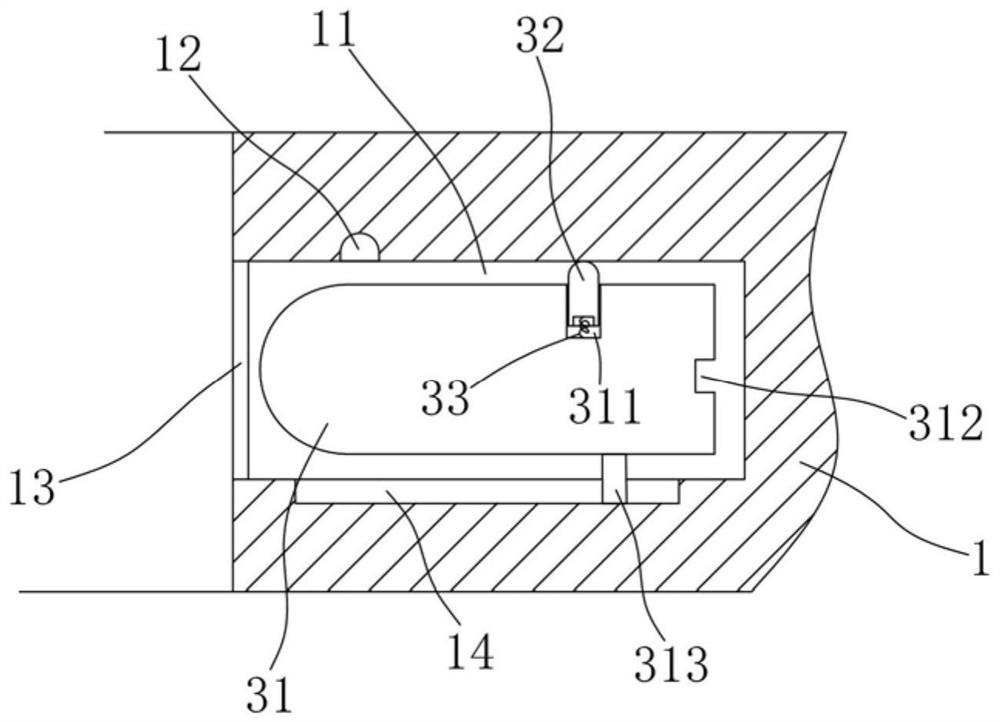

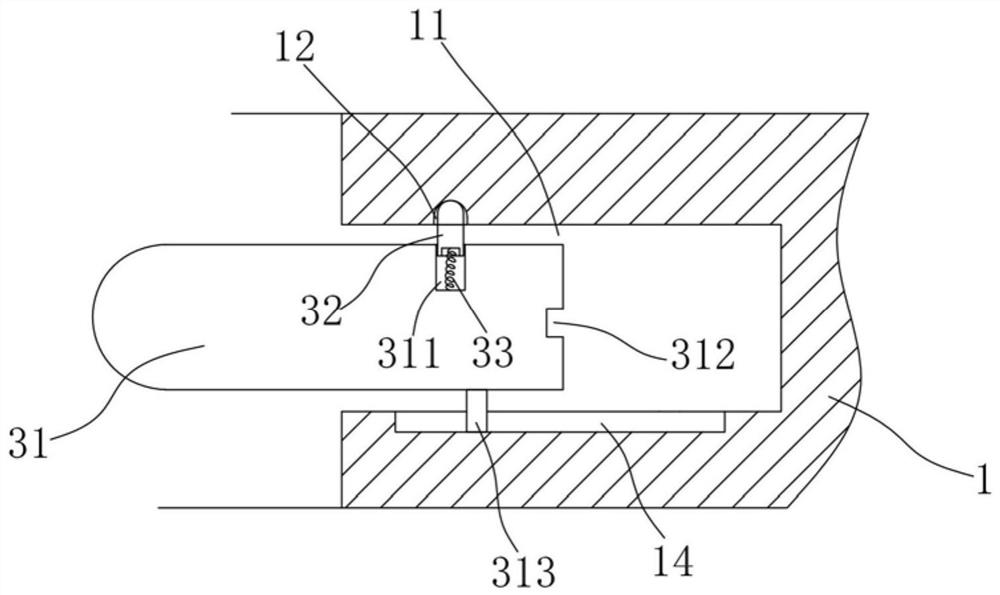

[0034] combine Figure 1-Figure 3 As shown, the flexible return capsule provided by this embodiment, which can avoid thermal melting of the airbag, includes a capsule body 1 , an airbag 2 and a barrier assembly 3 .

[0035] Among them, the cabin body 1 and the airbag 2 are mature structures, the cabin body 1 is the main structure of the return cabin, and the airbag 2 is used to open after the return cabin enters the atmosphere and surround the cabin body 1. On the one hand, it can reduce its falling speed. The protection cabin body 1 is not subjected to atmospheric friction and ablation, and on the other hand, also reduces the damage from ground or water surface impact when landing. The cabin body 1 is a cylindrical structure, and the outer surface of its side wall is provided with at least one set of installation grooves 11, and each set of installation grooves 11 includes a plurality of installation grooves 11 uniformly distributed along the circumferential direction, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com