A kind of quick disassembly 3D printing forming platform and using method

A 3D printing and fast technology, applied in the field of 3D printing, can solve problems affecting processing, damage, time-consuming and labor-intensive products, etc., and achieve the effect of simple structure, strong practicability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

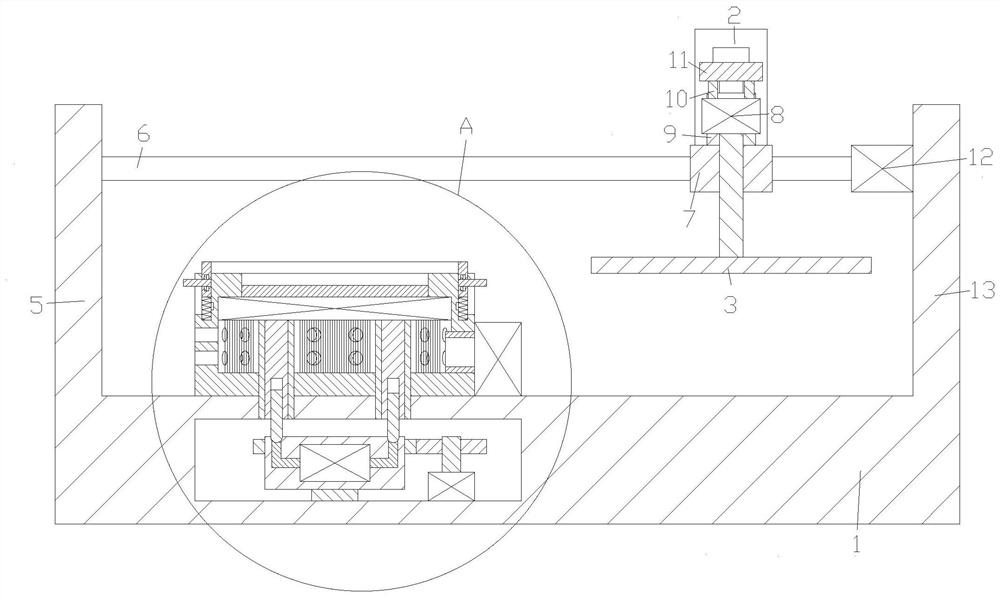

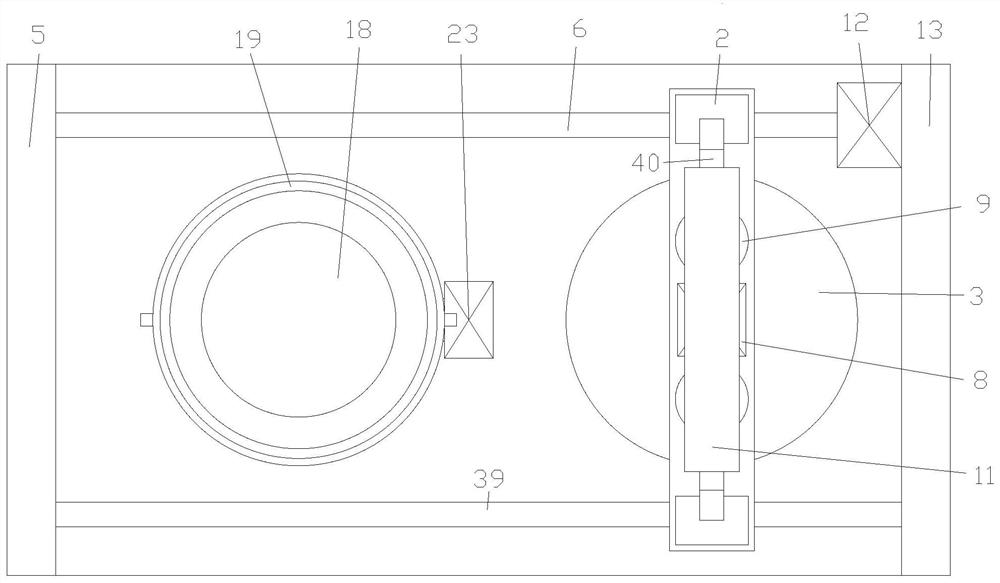

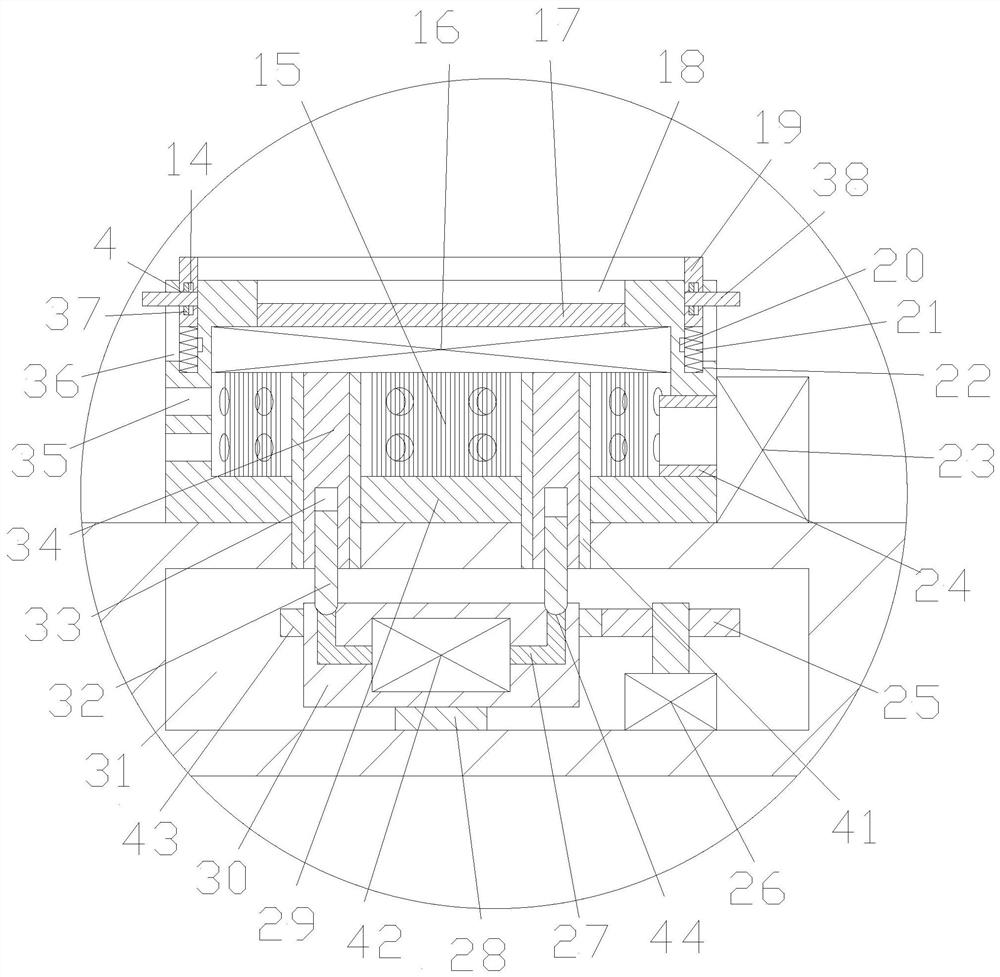

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Refer to attached figure 1 , 2 3. The quick-disassembly 3D printing molding platform in this embodiment includes a base 1, on which a box 29 is fixedly installed, and the top of the box 29 is provided with a port 18, and the inner wall of the port 18 is The heat conduction sheet 17 is fixedly installed, and the top of the inner wall of the box body 29 is fixedly installed with a semiconductor refrigeration sheet 16 in contact with the heat conduction sheet 17. The inside of the base 1 is provided with a switching cavity 31, and the bottom of the semiconductor refrigeration sheet 16 is symmetrically installed. After passing through the box body 29 and the base 1, it reaches the protection tube 41 inside the switching chamber 31. The bottom of the semiconductor cooling plate 16 is symmetrically provided with a first positive and negative copper column 34 fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com