Electromagnetic flow measuring and adjusting instrument

An electromagnetic flow, measuring and adjusting instrument technology, applied in the field of measuring and adjusting instruments, can solve the problems of reduced work efficiency, slow disassembly and assembly, cumbersome cable heads, etc., and achieves the effect of fast fixing and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

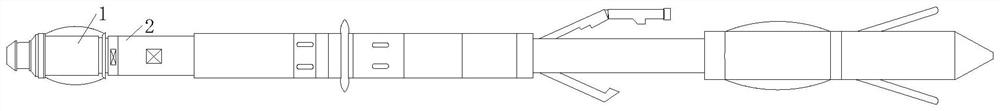

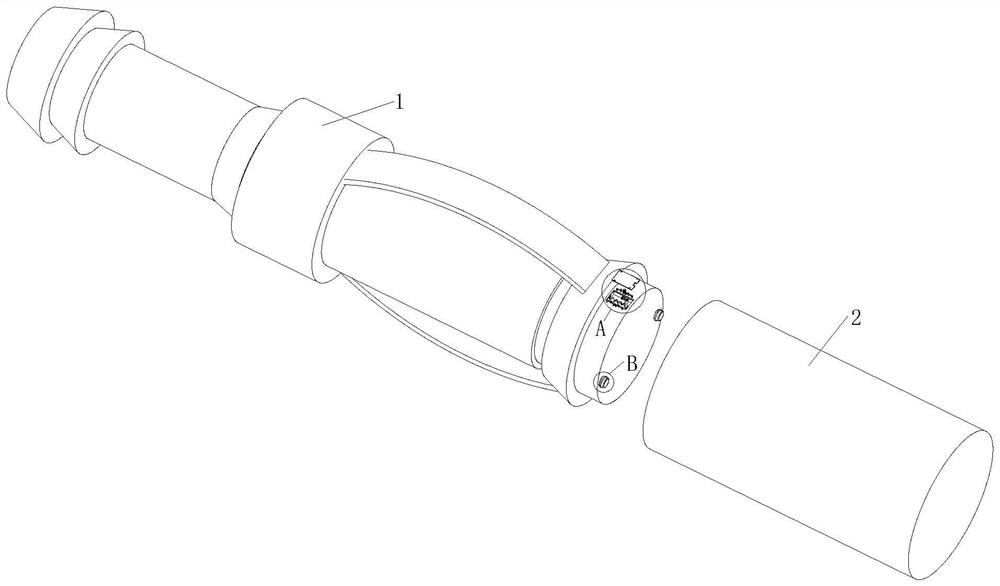

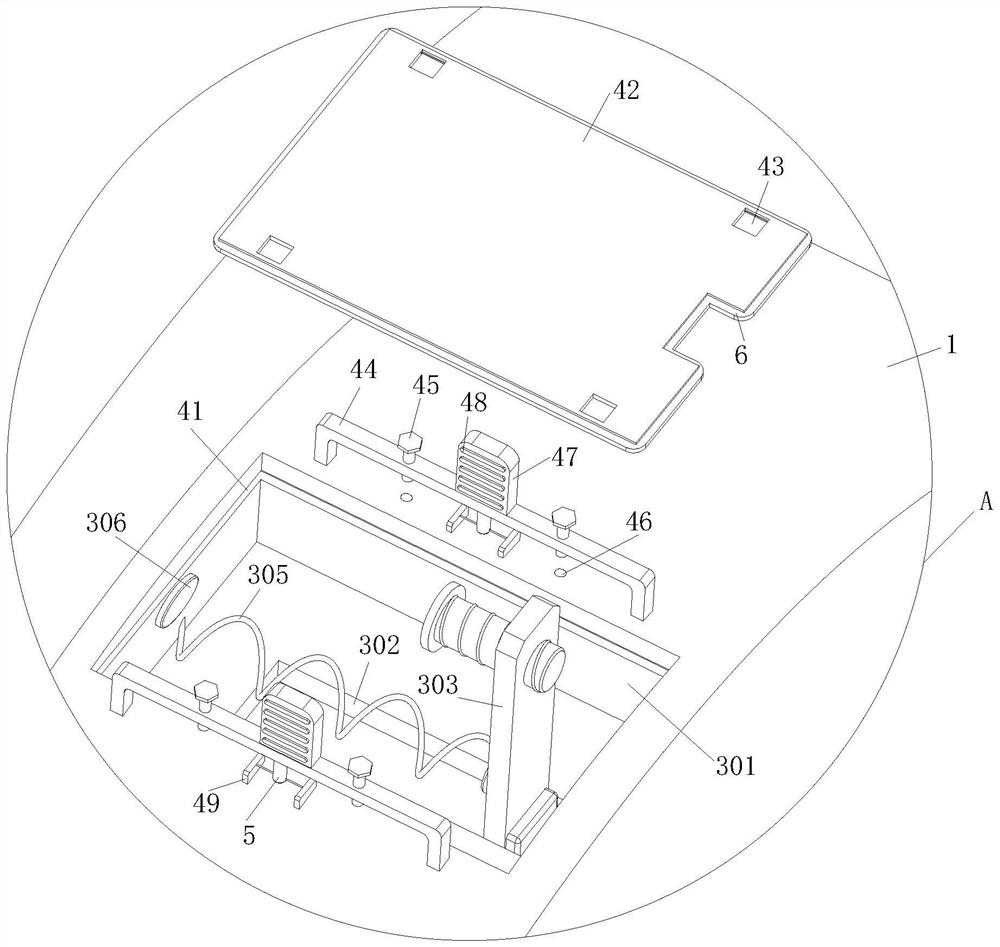

[0028] See Figure 1-6 As shown, the electromagnetic flow measurement includes a cable head 1, an electric current collecting control 2; an electric current collecting control 2 is provided on one side of the cable head 1, and two placed grooves 301 are opened on the surface of the cable head 1. , Two of the placed grooves 301 are symmetrically distributed in the central axis of the cable head 1, and the inner portion of the placement groove 301 is opened, and the inner sliding connection of the chute 302 has a sliding block 303, and the slider block 303 One side thread is connected to a first bolt 304, and one side of the placing groove 301 is fixedly mounted having a spring 305, and the other end of the spring 305 is fixedly mounted, and the one end of the electric current collecting control 2 is opened. When the first threaded hole 309 operates, the first thread 304 on the sliding block 303 and the first thread control 2 on the first threaded hole 309 on the same straight line, ...

Embodiment 2

[0037] See Figure 7 As shown, Comparative Examples 1, as another embodiment of the present invention, two round slots 7 have two round slots 7, and the two of the circle grooves 7 are distributed in a central axis symmetry distribution of the cable head 1; When working, when the cable head 1 is needed, by placing the hand into the round groove 7 of the cable head 1, it is convenient to pick up the cable head 1 by the round groove 7, and the round slot 7 increases friction. The role makes it to prevent slip when picking up the cable head 1.

[0038] Working principle, in front of the cable head 1, the sliding block 303 slides in the direction of the magnet positive electrode 306, and the sliding block 303 is moved together with the magnet negative electrode 307 such that the magnet positive electrode 307 and the magnet positive electrode 306 are attached to each other, and then the sliding block 303 Fixed, convenient for the mounting of the sliding block 303, before the cable head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com