Muddy water preventing structure suitable for various states of power head

A power head, anti-mud technology, applied in transmission parts, drilling equipment and methods, belts/chains/gears, etc., can solve the problems of reducing mud-proof and waterproof effect, power head without mud-proof ring, polluting lubricating oil, etc. , to achieve the effect of protecting long-term good operation, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

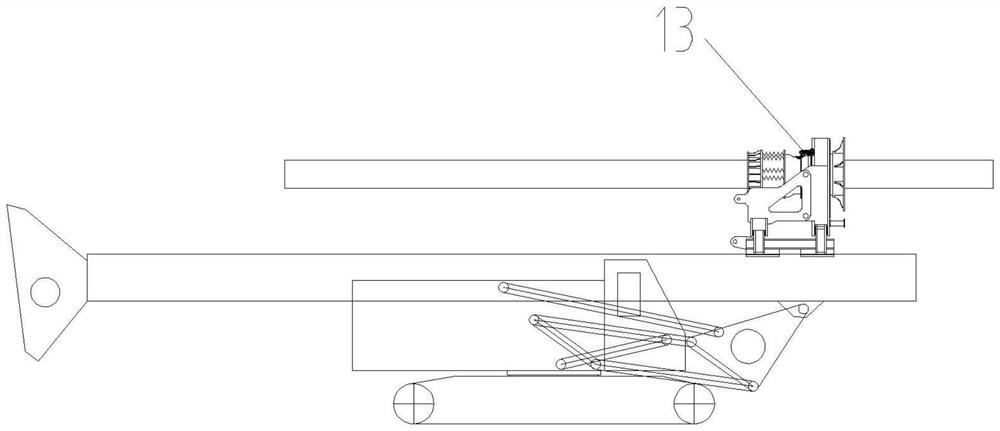

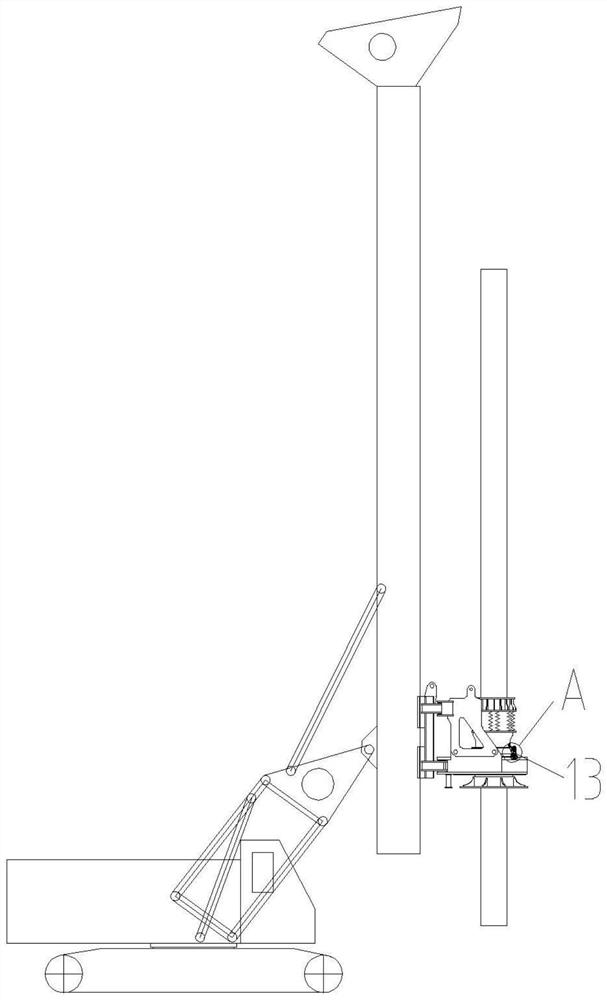

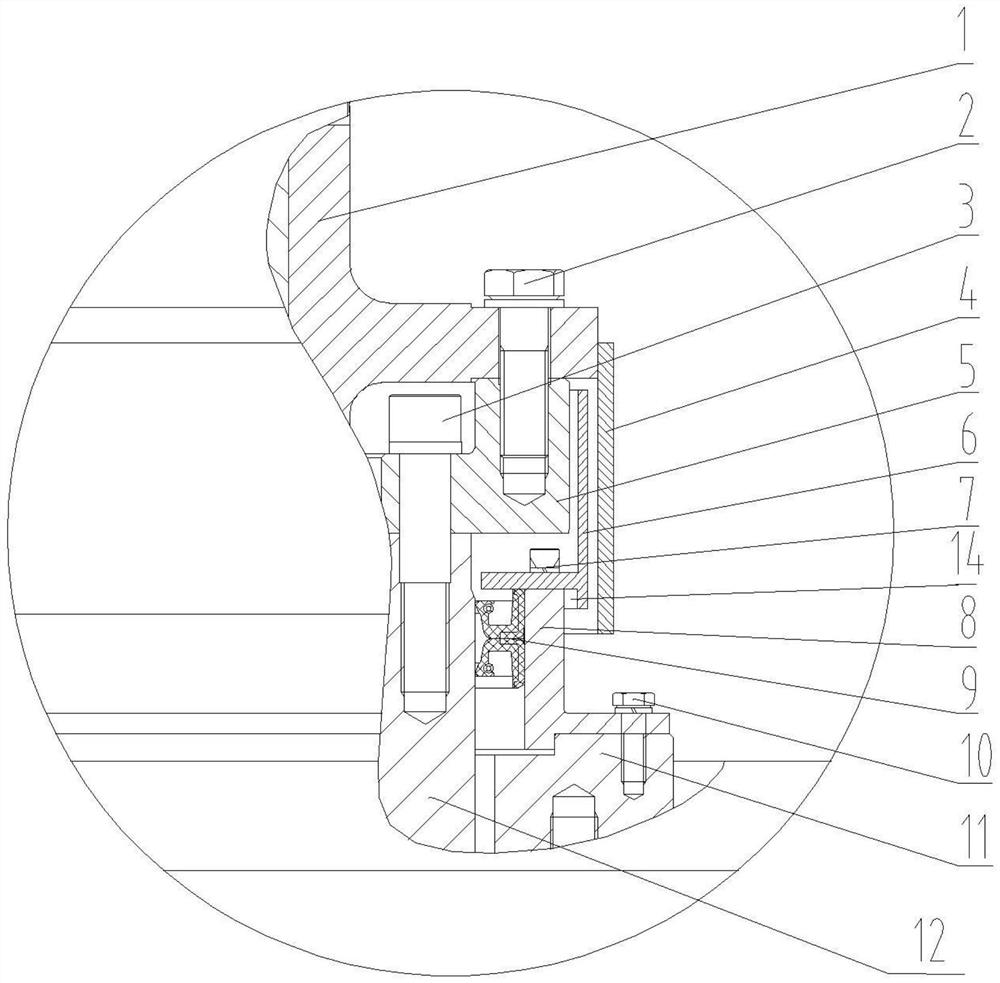

[0026] The following will combine Figure 1-3 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0027] A mud-water-proof structure suitable for various states of the power head, which includes a driving sleeve 1, a mud-proof outer ring 4, a connecting flange 5, an upper oil seal box 8, an upper oil seal 9, a power box body 11, and a transmission sleeve 12. The lower flange surface of the driving sleeve is fixedly connected to the upper flange surface of the connecting flange through bolt one 2, and the outer surface of the driving sleeve is connected to the mud-proof outer ring, and the lower flange surface of the connecting flange is connected through bolt two 3. It is fixedly connected with the upper flange surface of the drive sleeve. The space formed by the drive sleeve, the connecting flange, the mud-proof outer ring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com