Railway vehicle speed simulation experiment device and working condition simulation method

A rail vehicle and experimental device technology, applied in the field of sensor system detection of rail vehicles, to achieve the effect of easy portability, strong integrity, and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

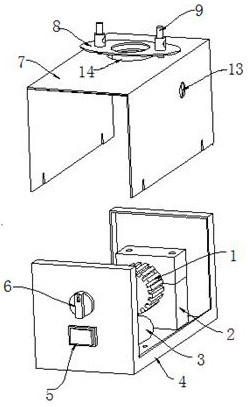

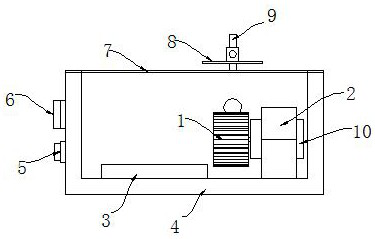

[0045] Such as Figure 1 to Figure 7 As shown, in this embodiment, a rail vehicle speed simulation experiment device is designed, including a power supply, a pseudo-speed runner 1, a pseudo-speed motor 10, a base 4, a cover, and a driving circuit.

[0046] Wherein, the pseudo-speed runner 1 is driven by the pseudo-speed motor 10, and the speed is detected by a speed sensor on the rail vehicle.

[0047] The base 4 is provided with a motor mounting base 2, the pseudo-speed motor 10 is fixed on the motor mounting base 2, and the base 4 is U-shaped. The power supply is electrically connected to the pseudo-speed motor 10 through the driving circuit; the power supply adopts the battery 3 and is installed on the inner bottom of the base 4 .

[0048] The drive circuit includes a speed control knob 6 and a switch 5, the switch 5 and the speed control knob 6 are installed on the side wall of the base 4; the changeover switch 5 is used to switch the rotation direction of the pseudo-spee...

Embodiment 2

[0054] Use the rail vehicle speed simulation experimental device in embodiment 1 to simulate the experimental method of wheel skid condition: comprise the following steps:

[0055] S11: matching and connecting a plurality of speed sensors to one of the speed simulation experiment devices; the plurality of speed sensors are respectively used to detect wheel axle speeds at different positions;

[0056] S12: Operate the rail vehicle so that it is in rapid braking detection and release the parking brake;

[0057] S13: Operate the switching switch 5 of the speed simulation experiment device, so that the steering and rotation speed of each pseudo-speed runner 1 are the same, and the rotation speed reaches the set value;

[0058] S14: Adjust the speed control knob 6 of any speed simulation experiment device to decrease the speed of the corresponding pseudo-speed wheel 1 .

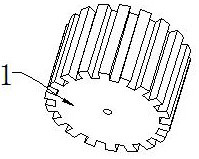

[0059] The pseudo-speed runner 1 is a gear, and gear teeth are evenly distributed around the gear; in the step...

Embodiment 3

[0062] Use the rail vehicle speed simulation experimental device in embodiment 1 to simulate the experimental method of wheel abnormal wear condition: comprise the following steps:

[0063] S21: matching and connecting a plurality of speed sensors to one of the speed simulation experiment devices; the plurality of speed sensors are respectively used to detect wheel axle speeds at different positions;

[0064] S22: Replace the quasi-speed runner 1 in any speed simulation experiment device with a missing gear; the missing gear is provided with a missing tooth position 11 in the circumferential direction;

[0065] S23: Operate the rail vehicle so that it is in a coasting state and release the parking brake;

[0066] S24: Operate the switching switch 5 of the speed simulation experiment device, so that the steering and rotation speed of each pseudo-speed runner 1 are the same, and the rotation speed reaches the set value.

[0067] Optional: in the step S24, if the speed detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com