Array substrate and display panel

A technology of array substrate and color filter substrate, which is applied in the field of display to improve the display effect and improve the effect of after-image after shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

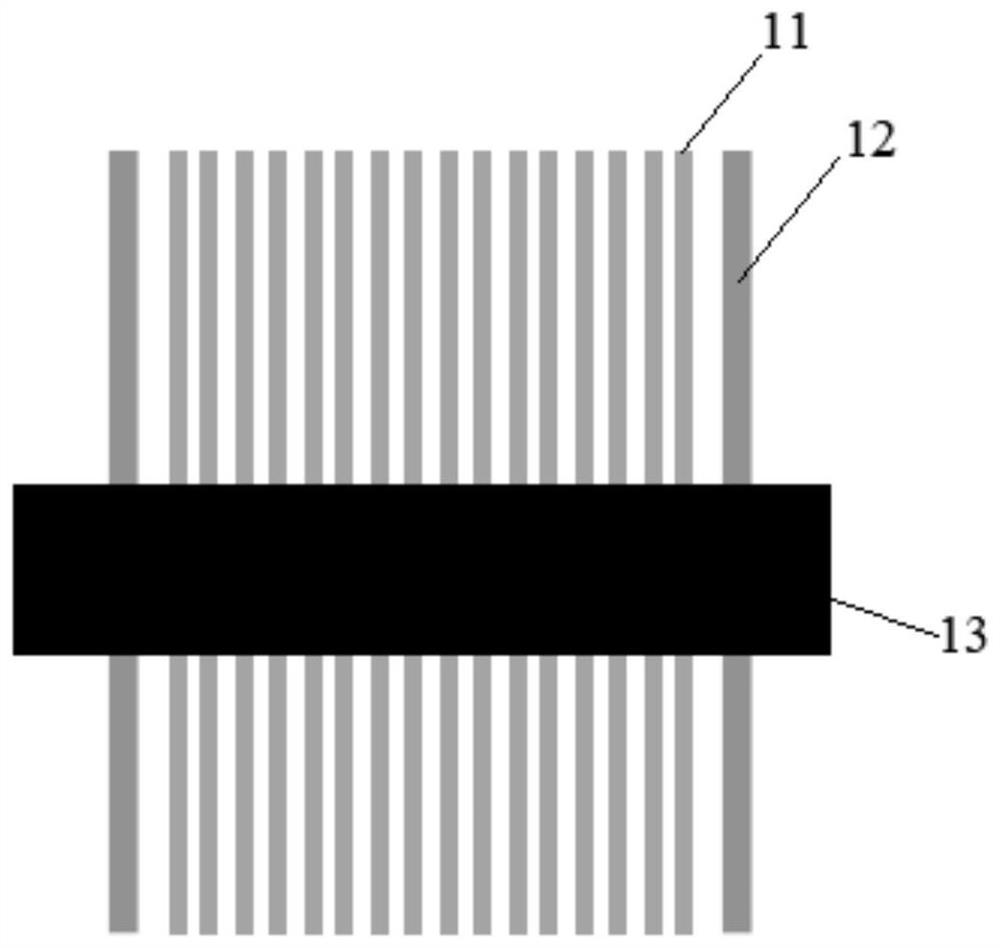

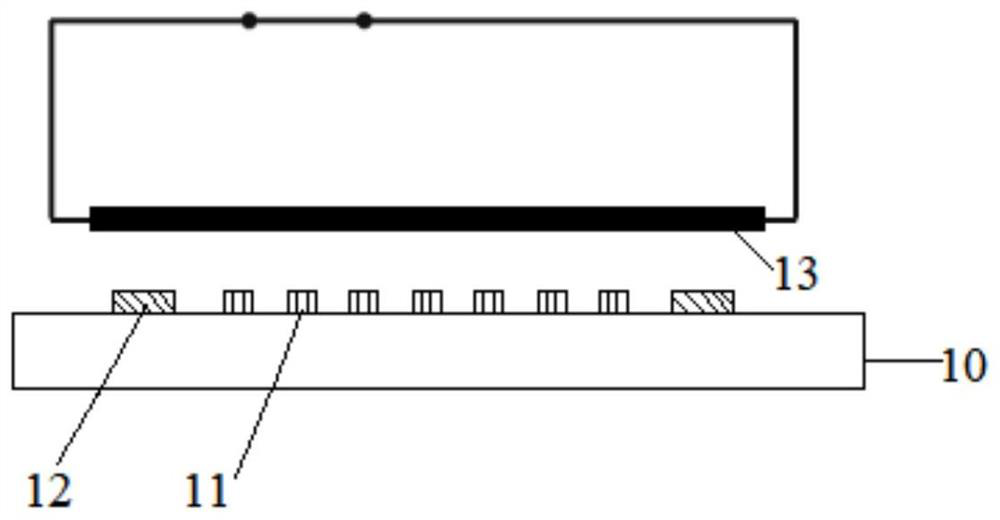

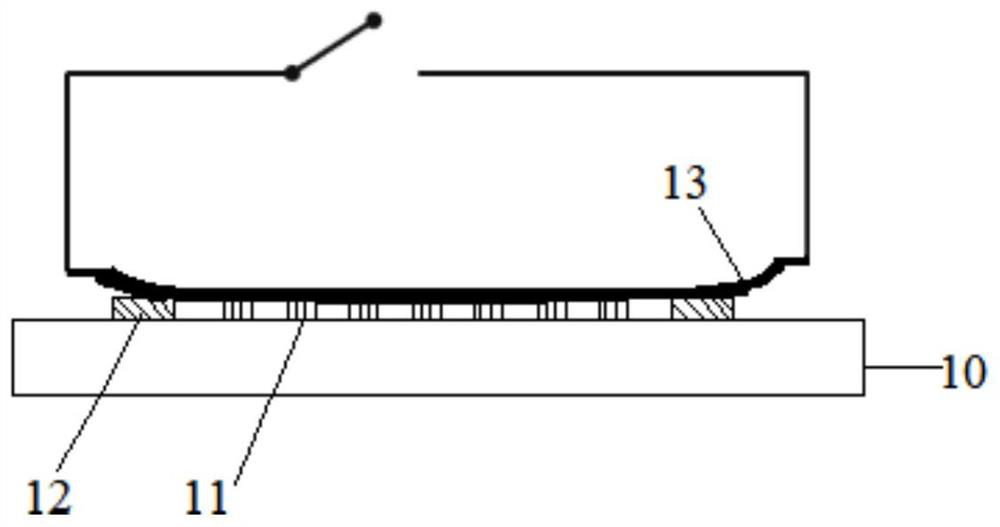

[0038] An array substrate, such as Figure 1-3 As shown, the array substrate includes a substrate 10 and a first lead 11 and a second lead 12 arranged in a non-display area on the substrate 10, the first lead 11 is electrically connected to the pixel electrode, and the second lead 12 is electrically connected to the common electrode or For the ground electrode, the array substrate also includes an electric actuation element 13, and the electric actuation element 13 includes at least one conductive layer; wherein, after the electric actuation element 13 changes from the power-on state to the power-off state, the electric actuation element The conductive layer of the device 13 is deformed and contacts at least part of the first lead 11 and at least part of the second lead 12 .

[0039]The array substrate of this embodiment is provided with a unique electric actuation component 13, which has the effect of electric actuation deformation. When the electric actuation component 13 ch...

no. 2 example

[0046] An array substrate, such as figure 1 , 4 As shown in -5, the array substrate includes a substrate 10 and a first lead 11 and a second lead 12 arranged in a non-display area on the substrate 10, the first lead 11 is electrically connected to the pixel electrode, and the second lead 12 is electrically connected to the common electrode or ground electrode, the array substrate also includes an electric actuation component 13, the electric actuation component 13 includes a laminated first material layer 131 and a second material layer 132, the first material layer 131 is located between the substrate 10 and the second Between the material layers 132, the first material layer 131 is a conductive layer, and the thermal expansion coefficient of the second material layer 132 is greater than that of the first material layer 131; The conductive layer on the lower surface of the actuating component 13 is deformed and contacts at least part of the first lead 11 and at least part of...

no. 3 example

[0055] A display panel includes the array substrate of the embodiment of the present application, a color filter substrate disposed opposite to the array substrate, and a liquid crystal layer located on the array substrate and the color filter substrate. Specifically, the array substrate includes a substrate 10 and a first lead 11 and a second lead 12 arranged in a non-display area on the substrate 10, the first lead 11 is electrically connected to the pixel electrode, and the second lead 12 is electrically connected to the common electrode or For the ground electrode, the array substrate further includes an electric actuation component 13, and the electric actuation component 13 includes at least one conductive layer; wherein, after the electric actuation component 13 changes from the power-on state to the power-off state, the electric actuation component The conductive layer 13 is deformed and contacts at least part of the first lead 11 and at least part of the second lead 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com