Flexible water-cooling heat dissipation device and use method

A water-cooling and heat-dissipating, flexible technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problem of increased frequency of alarm and shutdown of the stirring fan motor, and achieve the effect of wide water quality requirements and convenient scale cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

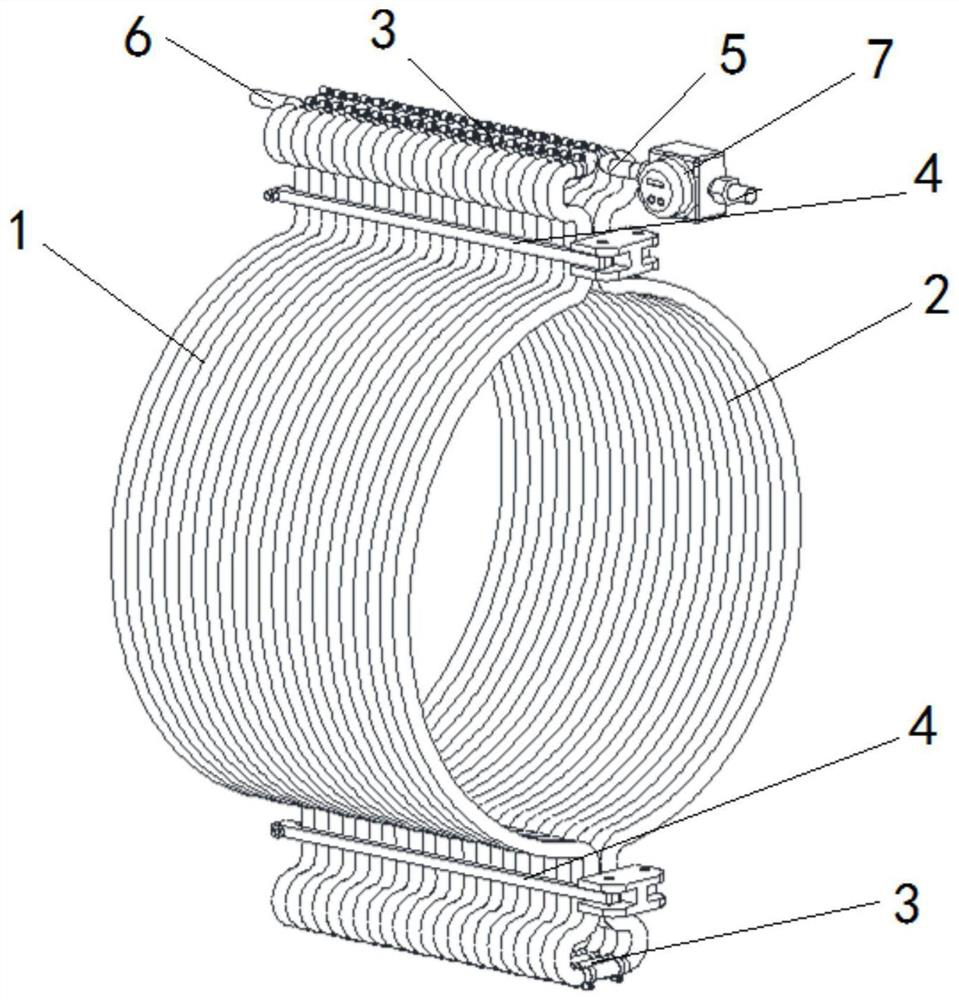

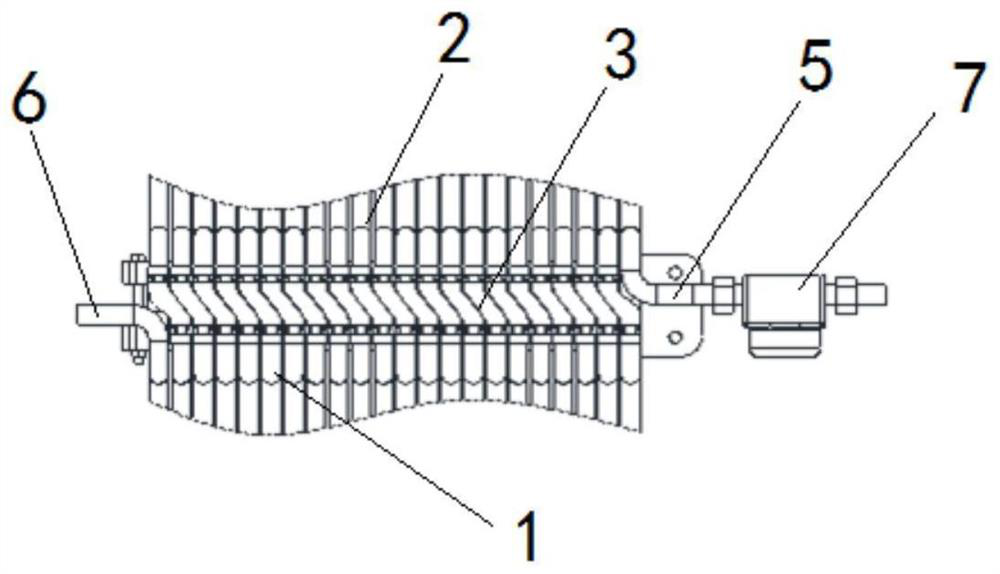

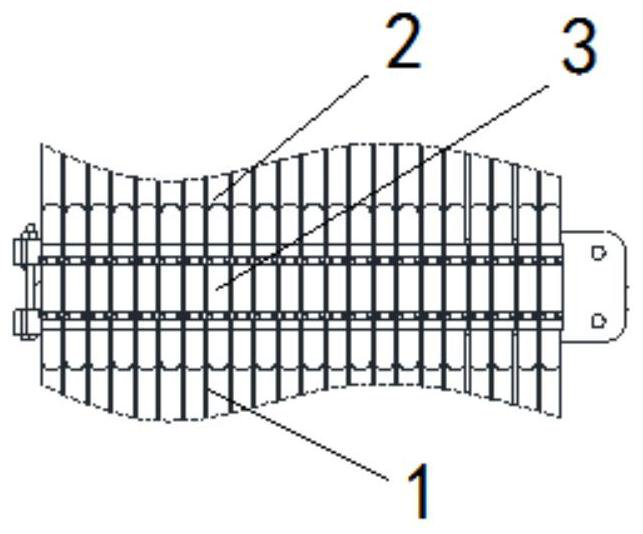

[0019] Referring to the accompanying drawings, the flexible water-cooled heat dissipation device of the embodiment is used to dissipate heat to the special motor 13. The main structure of the heat dissipation device includes a plurality of left heat dissipation pipes 1 and a plurality of corresponding right heat dissipation pipes 2 and two heat dissipation pipes for docking. A plurality of silicone rubber tubes 3 at the ends, the lower ends of the left cooling tube 1 and the right cooling tube 2 are flexibly connected through the silicone rubber tubes 3 respectively, as shown in image 3 As shown, the upper ends of the left radiating pipe 1 and the right radiating pipe 2 are connected sequentially through the flexible dislocation of the silicone rubber tube 3, as shown in figure 2 As shown, through the connection of the silicone rubber tube 3, the left heat dissipation pipe 1 and the right heat dissipation pipe 2 are connected to form a continuous cold water passage, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com