Special-shaped copper strip up-drawing continuous casting crystallizer and special-shaped copper strip production equipment

A continuous casting crystallizer and copper strip technology, which is applied in the field of continuous casting crystallizer and special-shaped copper strip production equipment, can solve the problems of high cost of special-shaped copper strip, unreliable upward cooling, and complicated process. Achieve the effect of easy copper strip size, low cost and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

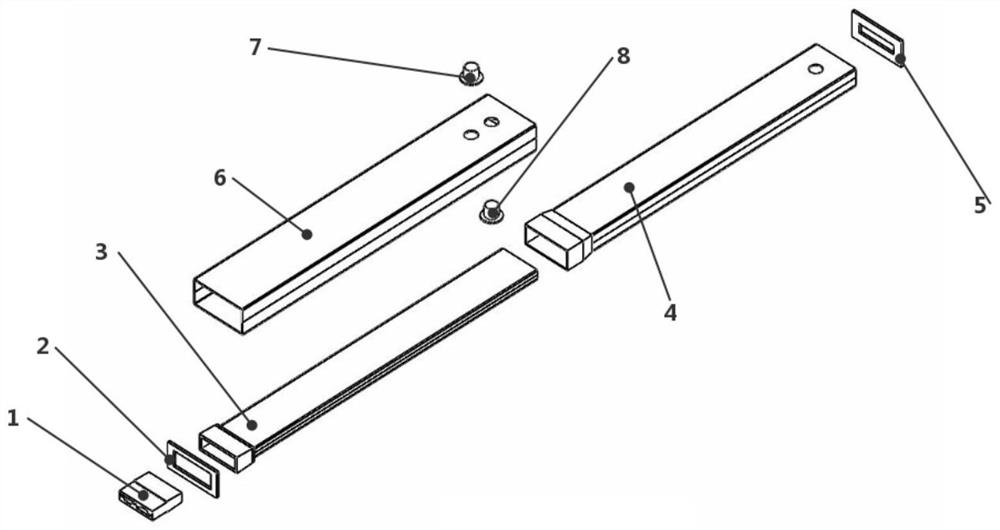

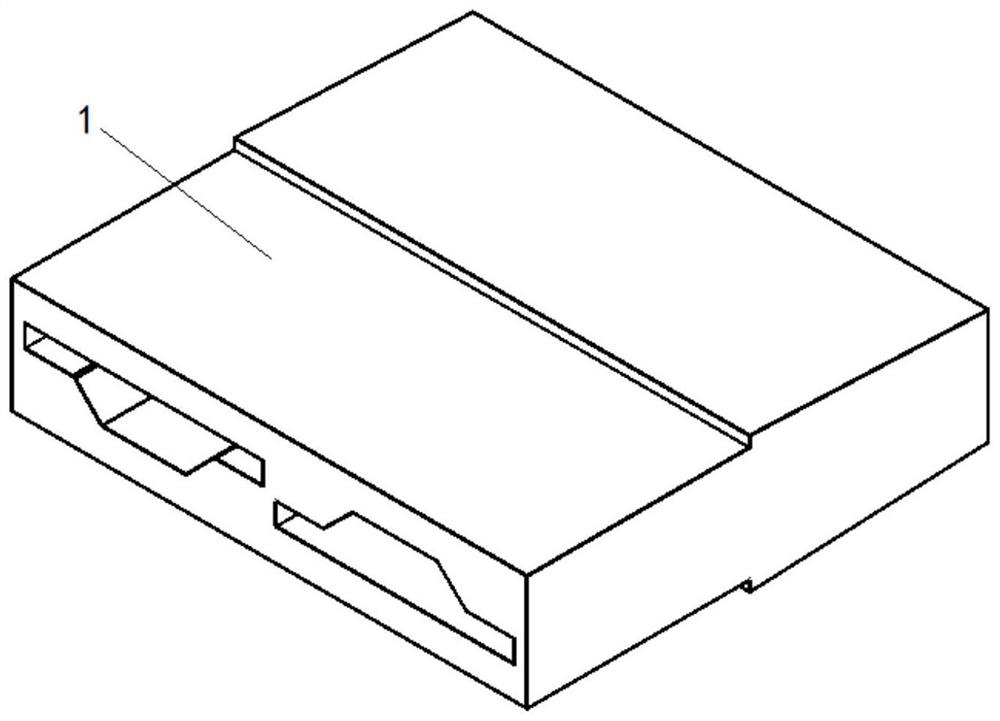

[0031]SeeFigure 1 to Figure 3In one embodiment, a special-shaped copper strip top-drawing continuous casting mold includes a graphite mold 1, a cooler, and a seal. among them,

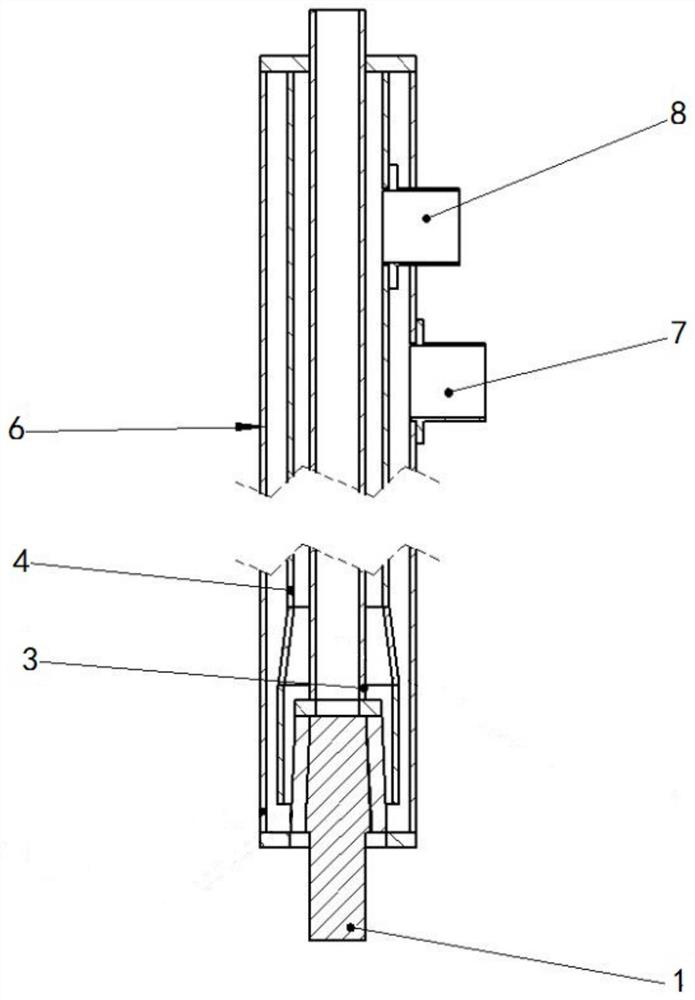

[0032]The cooler includes a shell 6, a middle tank 4, an inner tank 3, a water inlet unit 8, and a water outlet unit 7. The inner liner 3 passes through the outer shell 6, and the head end of the inner liner 3 is provided with a connecting groove, and the notch of the connecting groove is connected with the outer shell 6. The tail end of the inner bladder 3 is connected to the tail end of the housing 6 for connecting external devices. The middle bladder 4 is arranged between the inner bladder 3 and the outer shell 6. The middle bladder 4 cooperates with the inner bladder 3 to form a cooling liquid cavity, the middle bladder 4 cooperates with the outer shell 6 to form a liquid outlet cavity, and the cooling liquid cavity communicates with the liquid outlet cavity. The water inlet unit 8 penetrates the housing 6 ...

Embodiment 2

[0047]A special-shaped copper strip production equipment includes the special-shaped copper strip upward continuous casting mold of the first embodiment. By arranging the inner bladder 3 and the outer bladder in the shell 6 of the crystallizer, and cooperate to form a connected cooling liquid cavity and a liquid outlet cavity, and setting the liquid inlet and the liquid outlet so that the cooling liquid enters and exits from the cooling liquid cavity The liquid cavity flows out and then circulates after cooling. The special-shaped copper strip in the inner tank 3 is cooled during the flow in the two cavities. The cooling liquid has a large contact area with the inner tank 3 to ensure the cooling speed of the special-shaped copper strip to ensure the copper strip The production quality improves the qualification rate of special-shaped copper strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com