Circuit board connecting mechanism

A connection mechanism and circuit board technology, which is applied in the direction of printed circuits, printed circuits connected with non-printed electrical components, electrical components, etc., can solve the problems of small screw size, operator trouble, slow assembly speed, etc., and achieve assembly efficiency High, easy to operate, quick replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

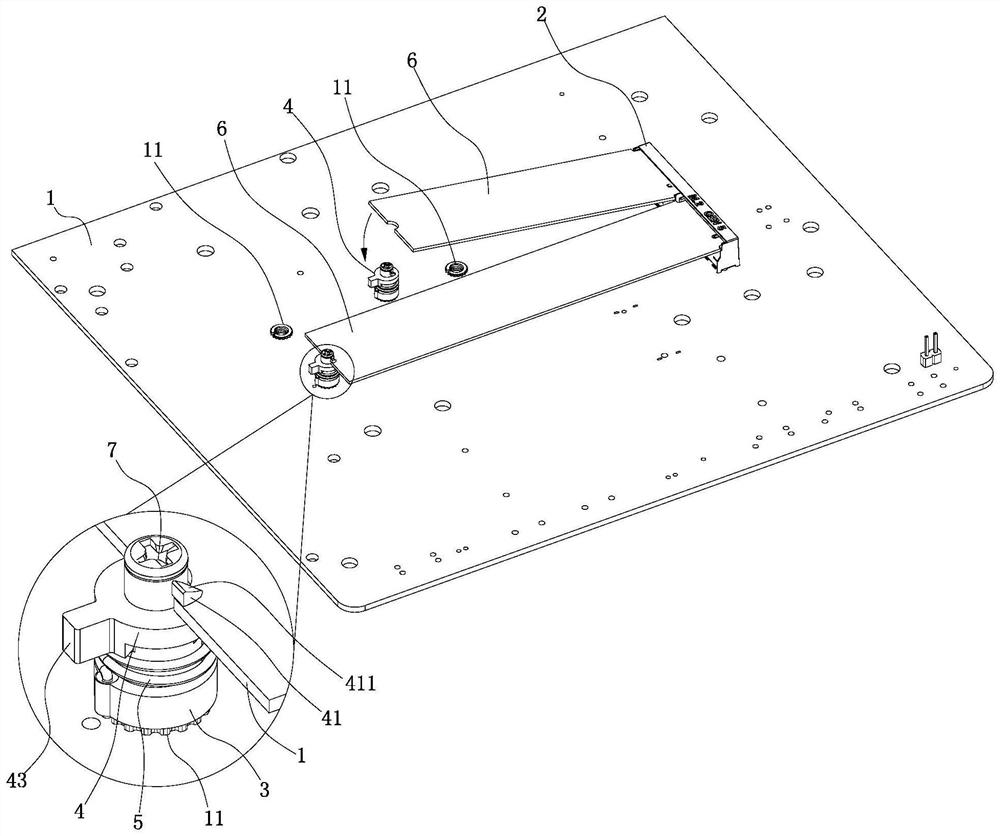

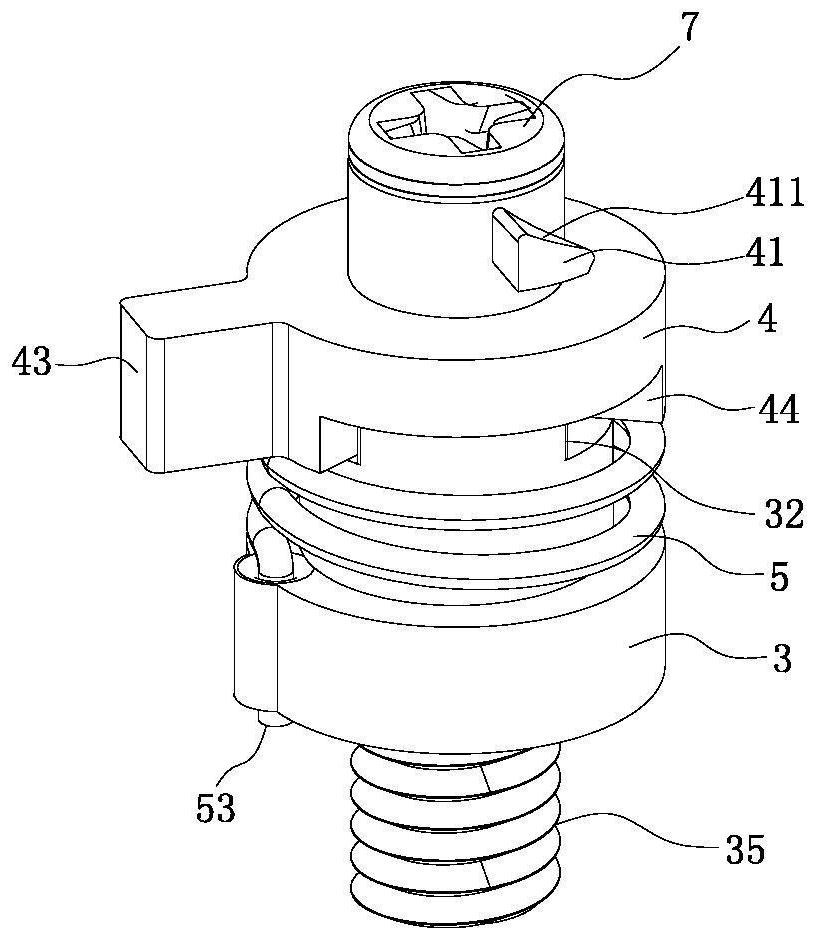

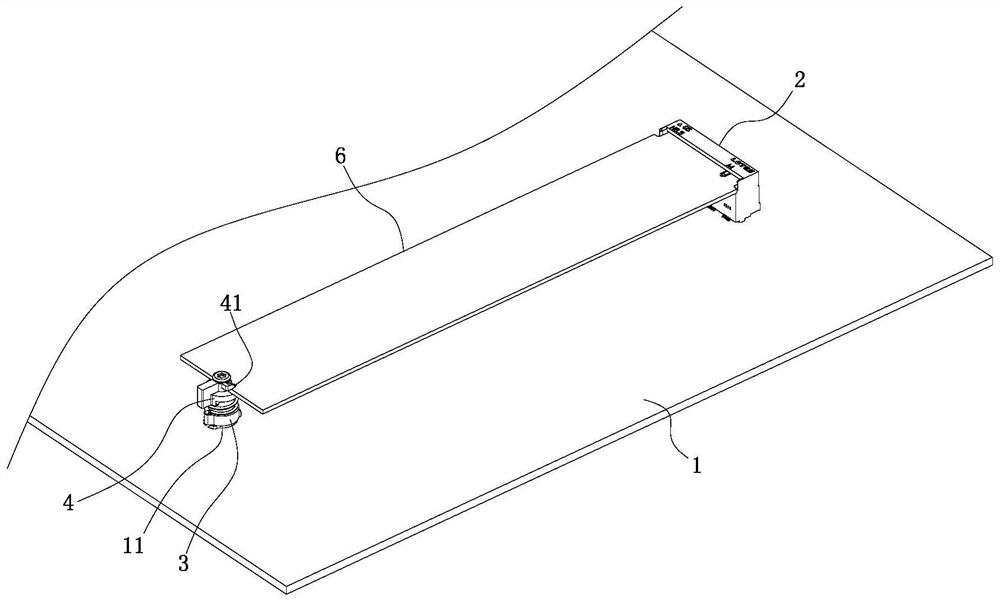

[0030] See Figure 1-9 Shown is a circuit board connection mechanism, which includes a circuit board 1 , a connector 2 , a fixing member 3 , a rotary buckle 4 and an elastic element 5 .

[0031] The connector 2 is fixed on the circuit board 1 and is used for plugging the electronic device 6 and forming an electrical connection so that data can be transmitted stably. In this embodiment, the electronic device 6 is an M.2 solid state drive. The M.2 solid-state drive is a solid-state drive with an M.2 interface. It is widely used on circuit boards due to its small size and high-speed transmission performance. For example, most computers currently use M. 2 SSDs.

[0032] The fixing part 3 is fixed on the circuit board 1 and can be disassembled relative to the circuit board 1; the rotating buckle 4 is mounted on the upper end of the fixing part 3 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com