Application method of PC component multi-form hoisting device

A hoisting device and multi-form technology, applied in the field of PC component multi-form hoisting devices, can solve the problems of destroying the use function of PC components, uneven lifting force, low construction efficiency, etc., and achieve simplified adjustment and leveling work, and even lifting force. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings:

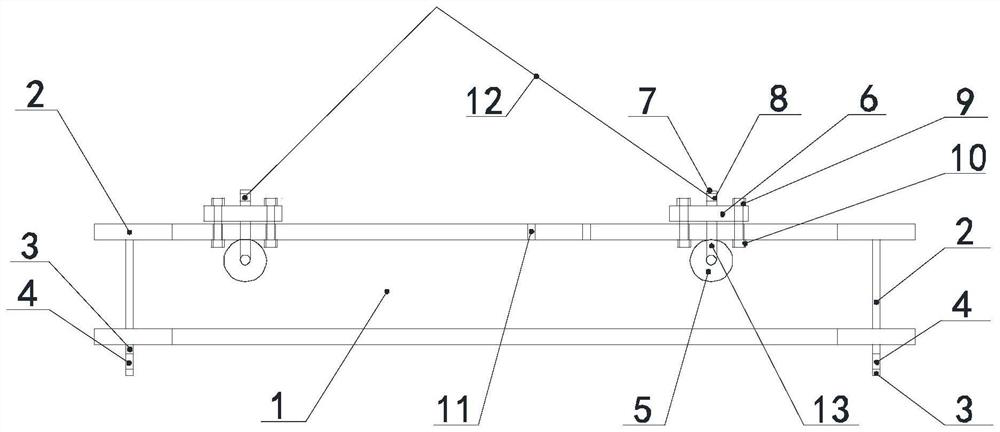

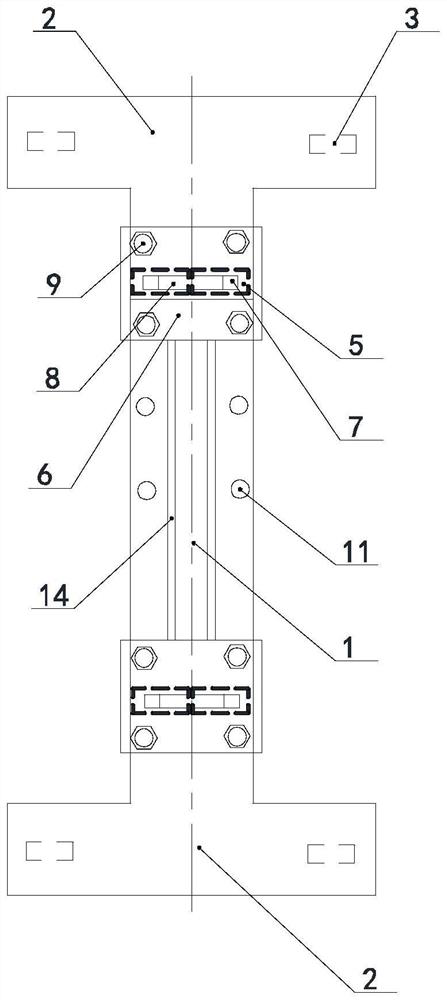

[0024] Such as figure 1 , 2 As shown, a PC member multi-form hoisting device and the method thereof include a tail beam 1, a tail-beam 2, a lifting tuning, a holes 4, a tail pulley 5, a hanging disk 6, lifting The lifting ear 7, the lifting hole 8, the fixing bolt 9, the fixing nut 10, the hanging rails, the centrifugal hole 11, the tail beam 1 side welding tail is tile beam 2, the lower end of the tail beam 2 is separately machined separately two hoisting The central position of the hanging ear 3, the central position of the lifting tunnel 3 is processed holes 4, the hoisting hoist 3 mounted in the tail-beam 2 is a lower surface of the upper surface of the hiped beam 1, the upper surface of the upper rail 5, which is responsible for the lifting PC member. The sliding rail pulley 5 rolls in the pulley rail 14, facilitating the hanging disk 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com