Method for designing tooth root transition curve of straight bevel gear

A straight-toothed bevel gear and transition curve technology, applied in the field of mechanical design and processing, can solve the problems of no consideration of the shape of the transition curve of the dedendum, no clear description of the dedendum modeling, and difficulty in controlling the design boundary, etc., to improve the bending strength, The effect of reducing the difficulty of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

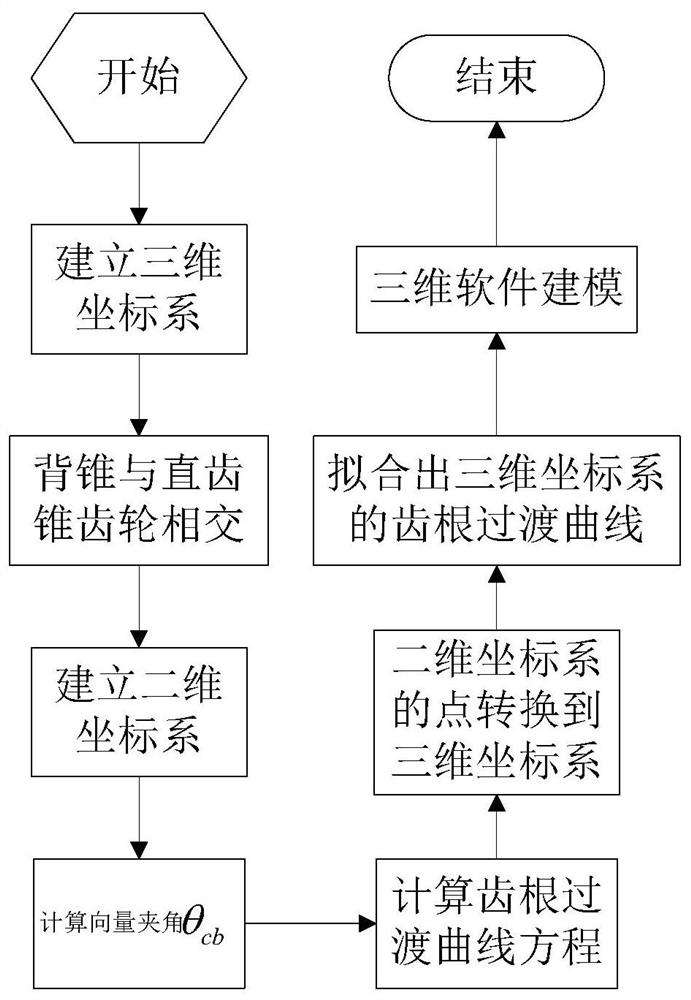

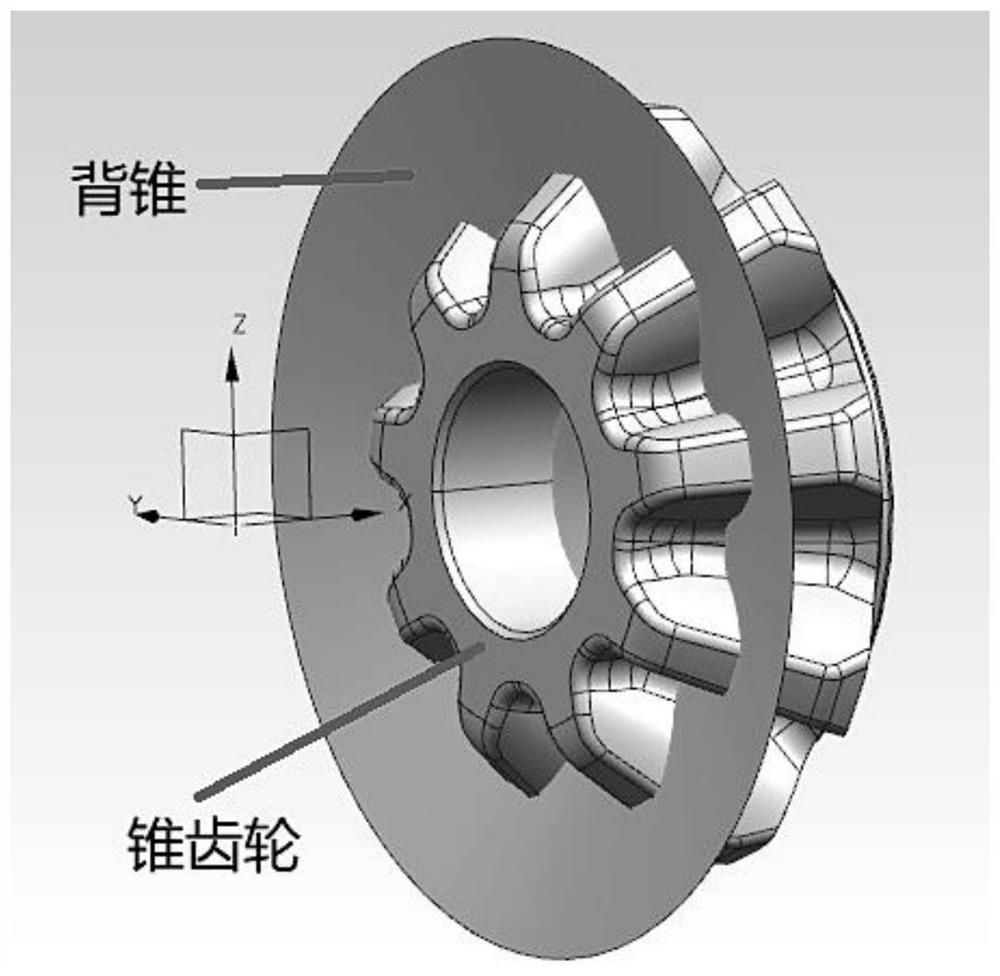

[0074] Such as Figure 1 to Figure 5 As shown, a method for designing the dedendum transition curve of a spur bevel gear includes the following steps:

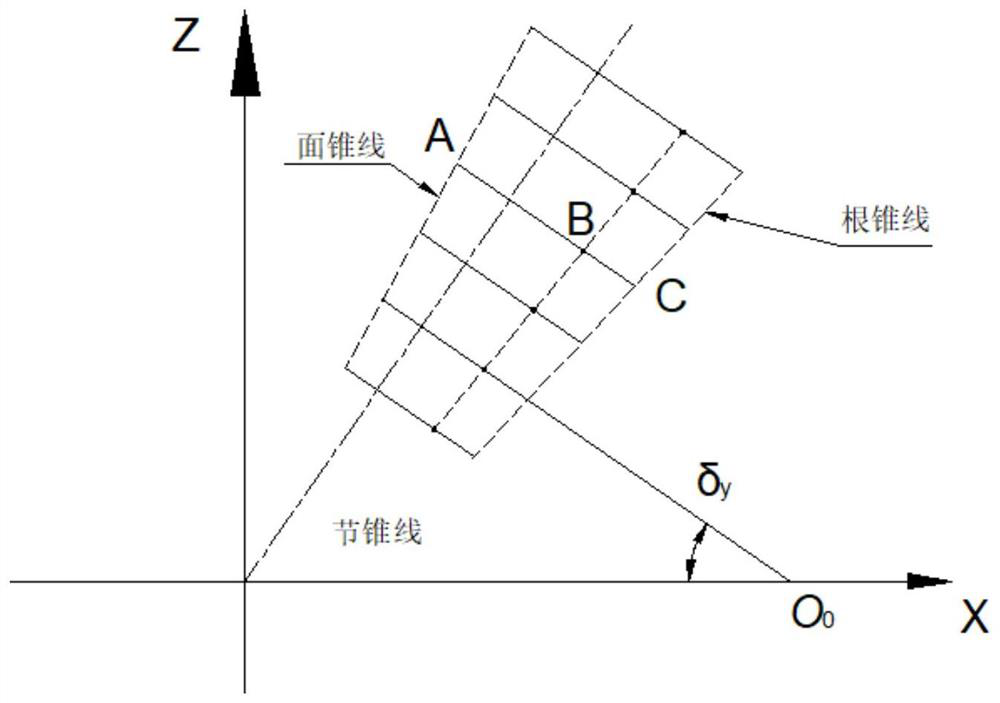

[0075] 1) Establish a three-dimensional coordinate system with the apex of the pitch cone of the straight bevel gear as the origin, the X-axis of the three-dimensional coordinate system is the central axis of the straight bevel gear, and the Y-axis and the Z-axis are the symmetry of the cross-section of the straight bevel gear axis;

[0076] 2) Intersect a back cone with known parameters and the cross section of the straight bevel gear, and set the intersection point of the back cone and the face cone of the straight bevel gear as A(x a ,y a ,z a ), the intersection of the back cone and the root cone of the straight bevel gear is C(x c ,y c ,z c ), the intersection of the back cone and the X axis is O 0 (x 0 ,0,0), the starting point of the root transition curve is B(x b ,y b ,z b ), the back cone is at point B(x b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap