Contact system of low-voltage circuit breaker

A low-voltage circuit breaker and contact system technology, applied in the directions of circuit breaker contacts and circuit breaker parts, etc., can solve the problems of slow arc striking speed of moving contacts and difficulty in adjusting spring positioning, and achieve fast arc striking speed, installation and installation. Simple and high breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

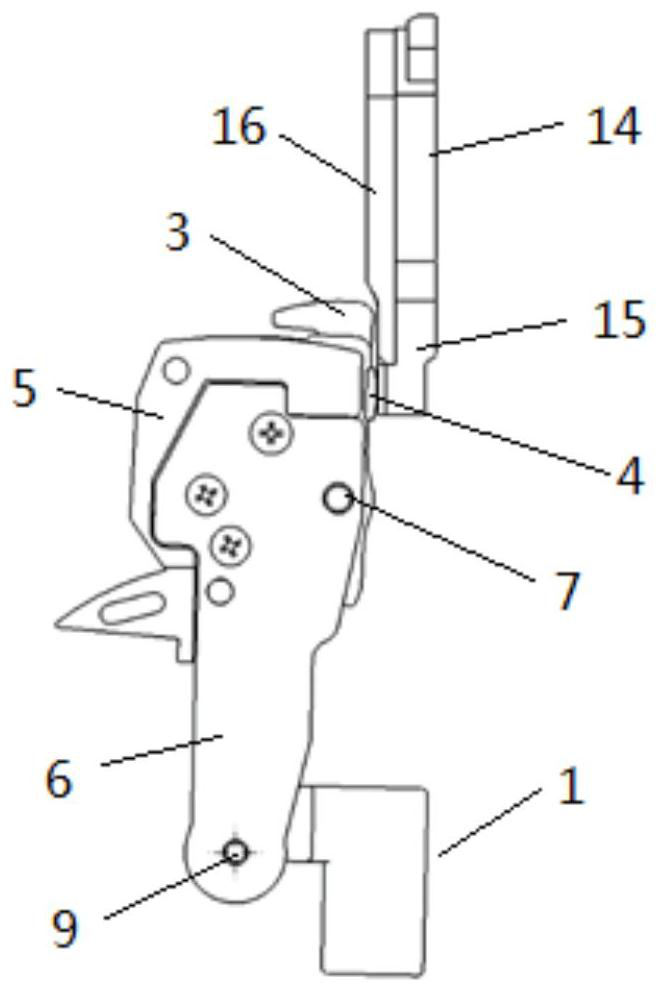

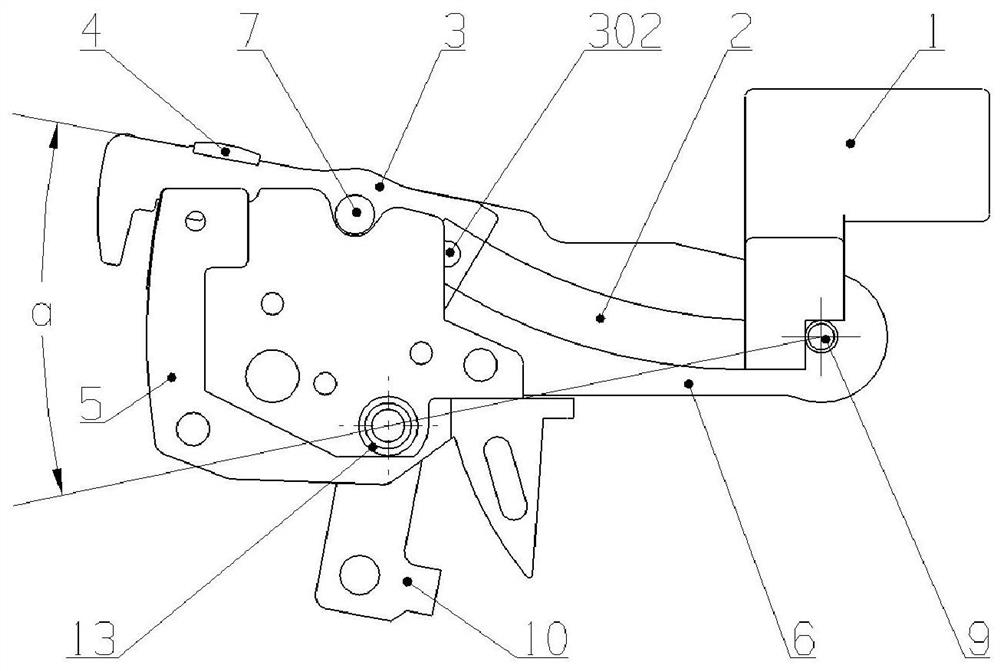

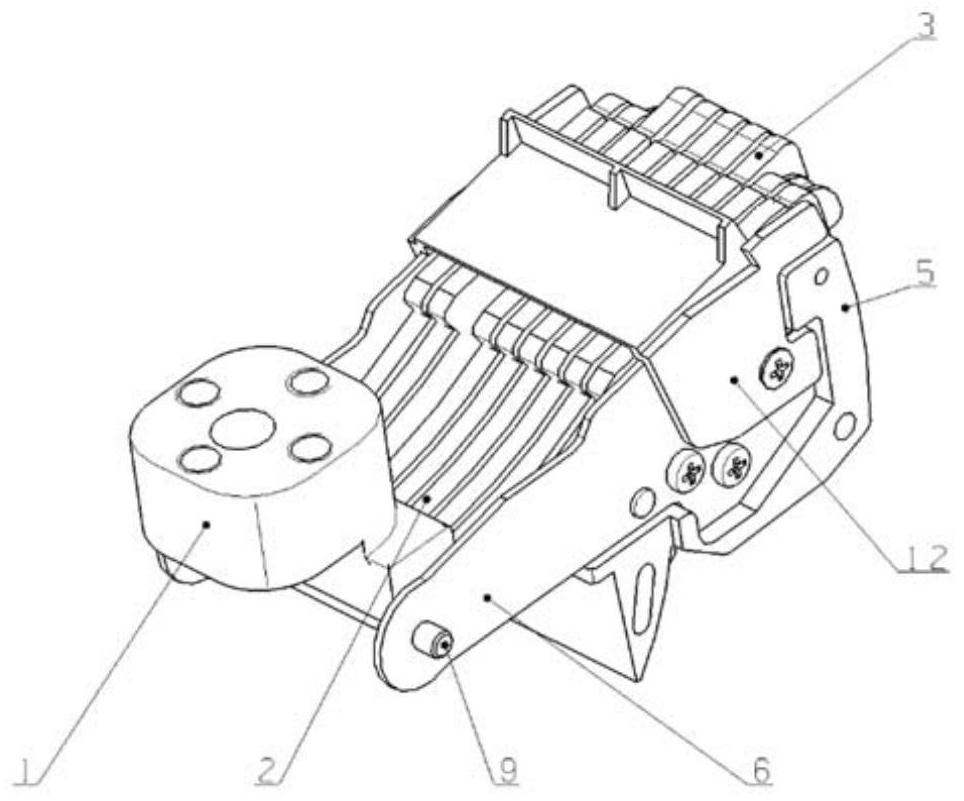

[0036] Such as Figure 1-9 As shown, a contact system of a low-voltage circuit breaker includes a moving contact system and a static contact system. The moving contact system includes a moving busbar 1, a soft connection 2, a contact piece 3, a contact support 5, a side Plate 6, first rotating shaft 7, contact spring 8, second rotating shaft 9, connecting rod 10, third rotating shaft 11, arc shield 12 and insulating liner 13; as Figure 2-3 shown.

[0037] The contact piece 3 has many pieces, and the present embodiment takes 9 pieces as an example, and the nine moving contact pieces 3 are connected side by side on the first rotating shaft 7 through the first shaft hole 303 on it and can rotate around the first The rotating shaft 7 rotates, the first rotating shaft 7 is installed on the contact support 5, and the contact spring 8 is installed on the contact support 5; the nine moving contact pieces 3 include five intermediate sequence moving contact pieces m and four pieces T...

Embodiment 2

[0045] In this embodiment, both the moving contact piece m in the middle sequence and the moving contact piece n on both sides are provided with an arc strike angle 305, and the α angle of the moving contact piece m in the middle sequence is larger than the α angle of the moving contact piece n on both sides by 1 -2 degrees, when the short circuit is broken, the arc strike angle 305 of the moving contact pieces m in the middle sequence will be disconnected from the static contact system later than the arc strike angle 305 of the moving contact pieces n on both sides. Concentrate the arc on the moving contact piece m of the intermediate sequence, and the arc quickly enters the arc extinguishing chamber along the surface of the arc leading piece 16, and the width D of the leading arc piece 16 is 2-3mm larger than the total width d of the moving contact piece m of the middle sequence . The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com