Split type protective needle cylinder device

A split-type, syringe technology, applied in the field of medical appliances, can solve the problems of insufficient strength, random swing, easy hanging, etc., to achieve the effect of quick and safe use, sufficient rotation angle, and not easy to accidentally open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

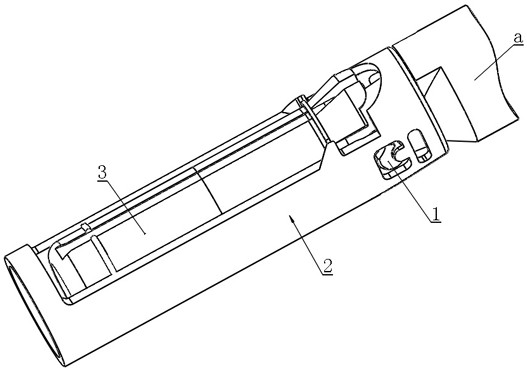

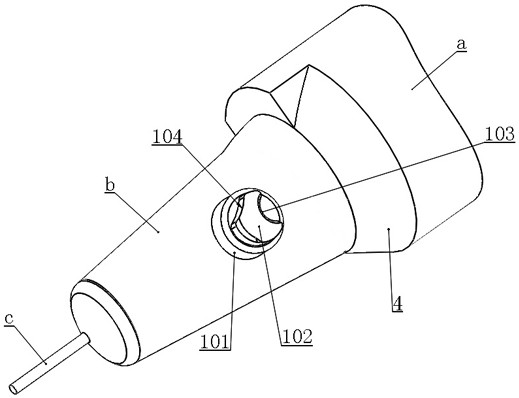

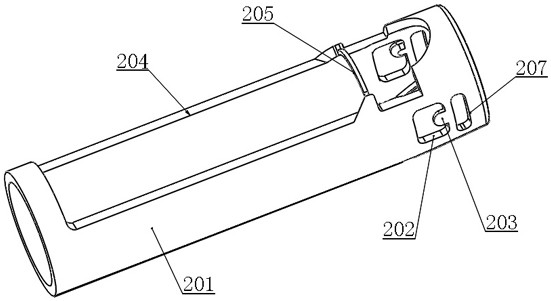

[0034] Example: as attached Figure 1-5 As shown, a split-type protective syringe device includes a cylinder body a, a needle installation tube b, and a needle c, and also includes a fixed shaft unit 1 arranged on the needle installation tube b, hingedly arranged on the fixed A rotating outer tube unit 2 on the shaft unit 1 and used for structural protection of the needle c, and a rotating outer tube unit 2 sleeved on the needle installation tube b and located in the rotating outer tube unit 2 and used for sealing the needle c The protected inner tube unit 3, the rotating outer tube unit 2 performs a position-limiting and fixing operation on the inner tube unit 3 before rotation, and pushes and removes the inner tube unit 3 when rotating.

[0035] In this embodiment, the rotating outer tube unit 2 is flush with the barrel a before and after use of the syringe device, and forms an acute angle with the barrel a when in use. , which means that the rotating opening angle of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com