Disinfection water tank for AES antibacterial protection channel

A water tank and channel technology, applied in the field of disinfection water tanks for AES antibacterial protection channels, can solve the problems of increasing control equipment investment, reducing fogging effect, increasing production cost, etc., so as to improve fogging efficiency, improve fogging effect, and avoid loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

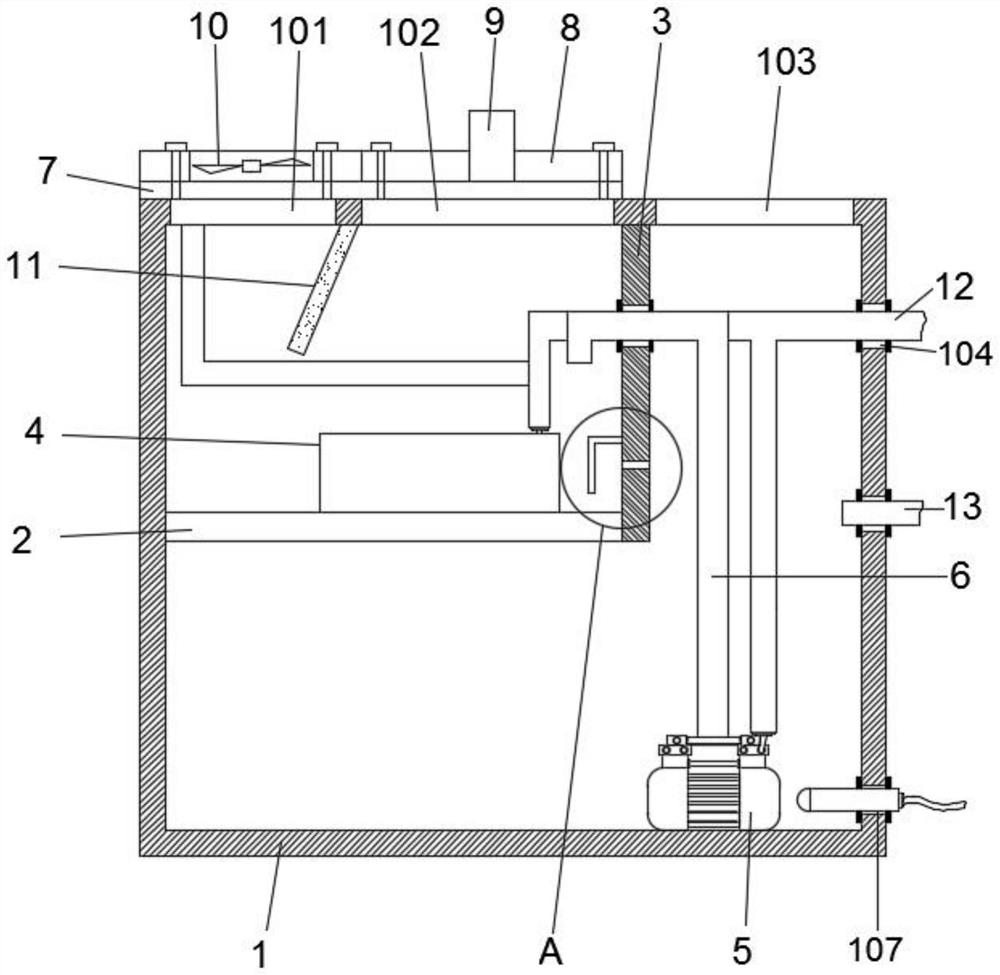

[0032] Such as Figure 1-3 As shown, a disinfection water tank for an AES antibacterial protection channel, including

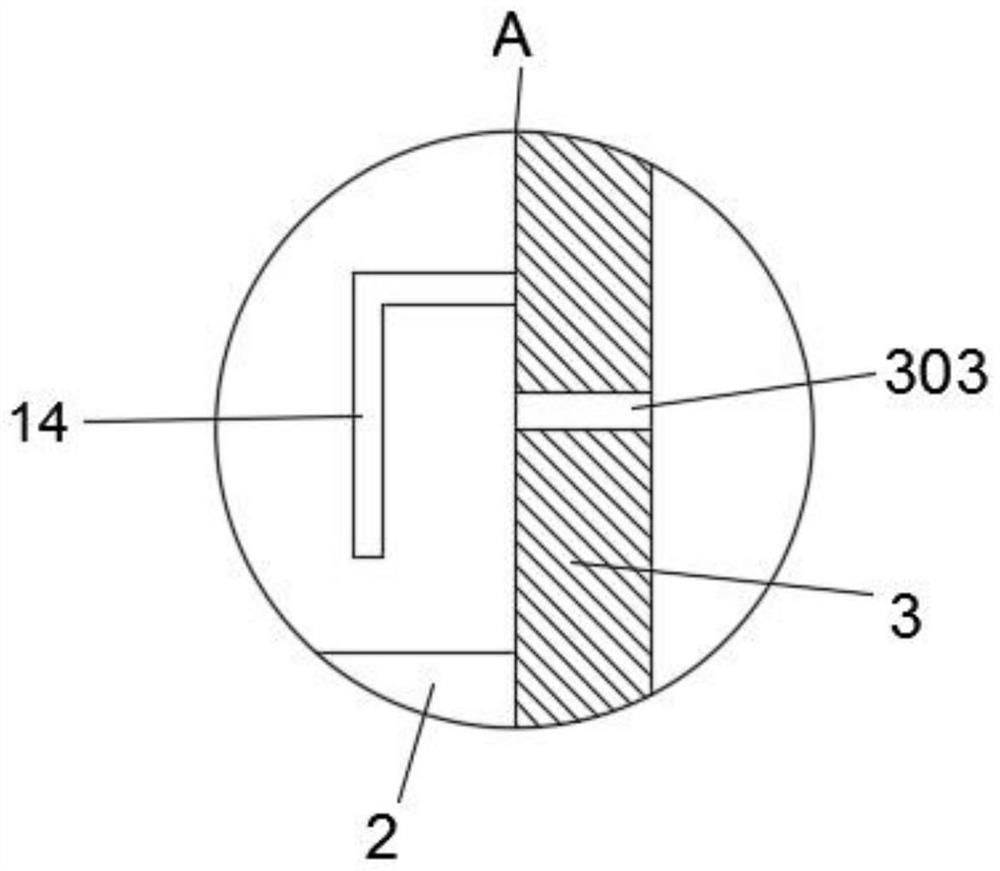

[0033] Box 1, the left side wall of the box 1 is fixed with a horizontal partition 2 and a longitudinal partition 3, and the horizontal partition 2 and the longitudinal partition 3 divide the box 1 into an atomization area and a liquid storage area , an atomizer 4 is installed in the atomization area, a water pump 5 is installed in the liquid storage area, a round hole 301 and a return groove 303 are arranged on the longitudinal partition 3, and the return flow groove 303 is located in the round hole The lower side of 301 is set in a flat shape, the side of the longitudinal partition 3 close to the transverse partition 2 is fixed with a baffle 14, the output end of the water pump 5 is connected to a water pipe 6, and the end of the water pipe 6 away from the water pump 5 runs through The round hole 301 extends into the atomization area;

[0034] The sealing...

Embodiment 2

[0038] On the basis of embodiment 1, the similarities with embodiment 1 will not be repeated, the difference is that, as Figure 2-6 As shown; the baffle 14 is L-shaped, including a connecting portion and a flow blocking portion, the connecting portion is located on the upper side of the backflow groove 303, the bottom end of the flow blocking portion extends to the lower side of the flow return groove 303, and the flow blocking portion There is a gap between the bottom end and the upper side of the transverse partition plate 2 .

[0039] The atomizer 4 is fixed on the upper side of the transverse partition 2 by screws, and the water pump 5 is fixed on the bottom wall of the box body 1 by screws.

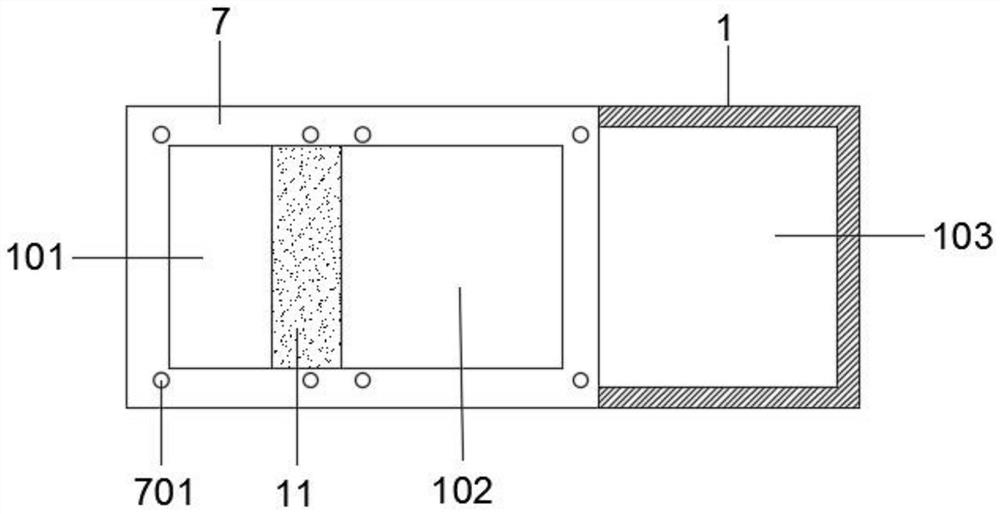

[0040] The top of the box body 1 is fixedly installed with a connecting plate 7, and the top of the box body 1 is sequentially provided with an air inlet 101, an air outlet 102, and an installation port 103 from left to right, and the deflector 11 is close to the air inlet 101 The ...

Embodiment 3

[0051] On the basis of the above embodiments, the difference is that, as figure 1 As shown; also includes a wire tube 12, used to dredge the various wires inside the box body 1, one end of the wire tube 12 extends to the outside of the box body 1 through the first wire hole 104, and the other end of the wire tube 12 passes through The second electric wire hole 302 extends to the inside of the atomizing area, and the electric wires of the fan 10 , the atomizer 4 and the water pump 5 all go through the electric pipe 12 and are connected to the external power supply.

[0052] Connect the wires of the fan 10, atomizer 4 and water pump 5 through the connection of the wire tube 12 to other PVC pipes, and lead out the box body 1 through the wire tube 12, which plays a good insulating role on the one hand and ensures the box body on the other hand. The neat internal wiring of the box body 1 effectively utilizes the internal space of the box body 1, and at the same time can ensure a go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com