Wind shield system for reducing oil injection lubrication wind resistance loss of high-speed spiral bevel gear

A spiral bevel gear and oil-injection lubrication technology, applied in the field of windshield system, can solve the problems of poor lubrication and cooling effect, wind resistance power loss, performance degradation of transmission system, etc., so as to reduce wind resistance power loss and reduce wind resistance power loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

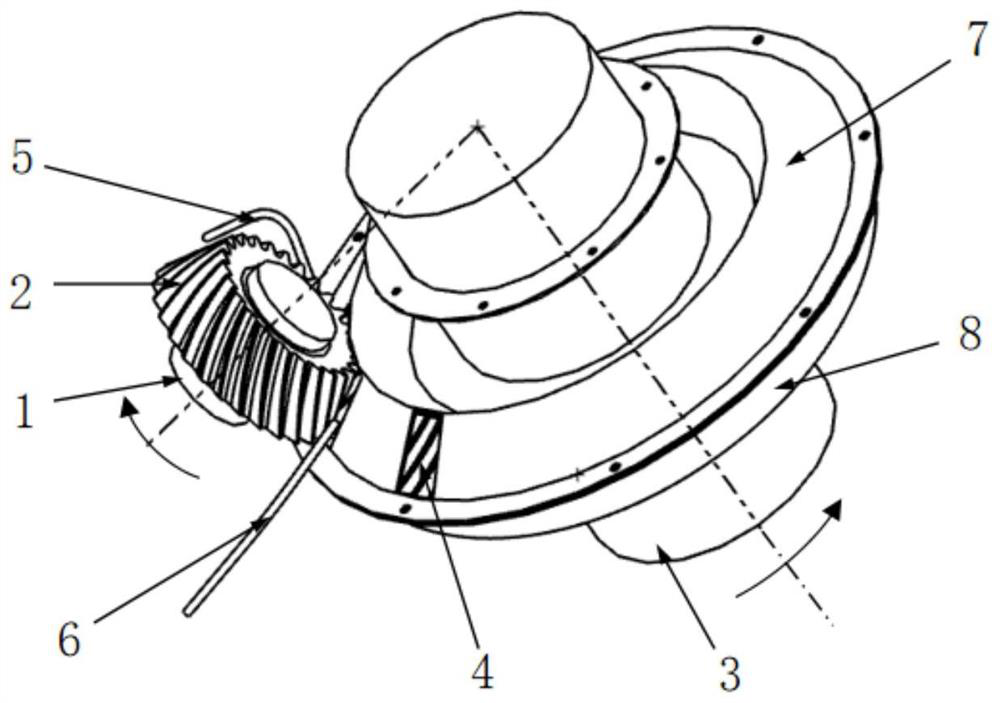

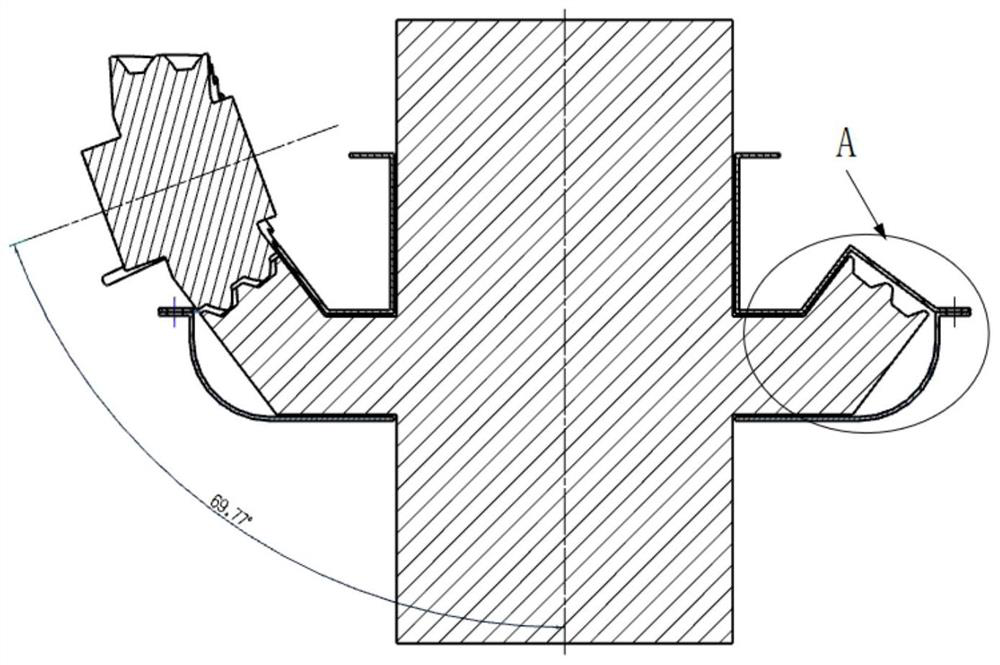

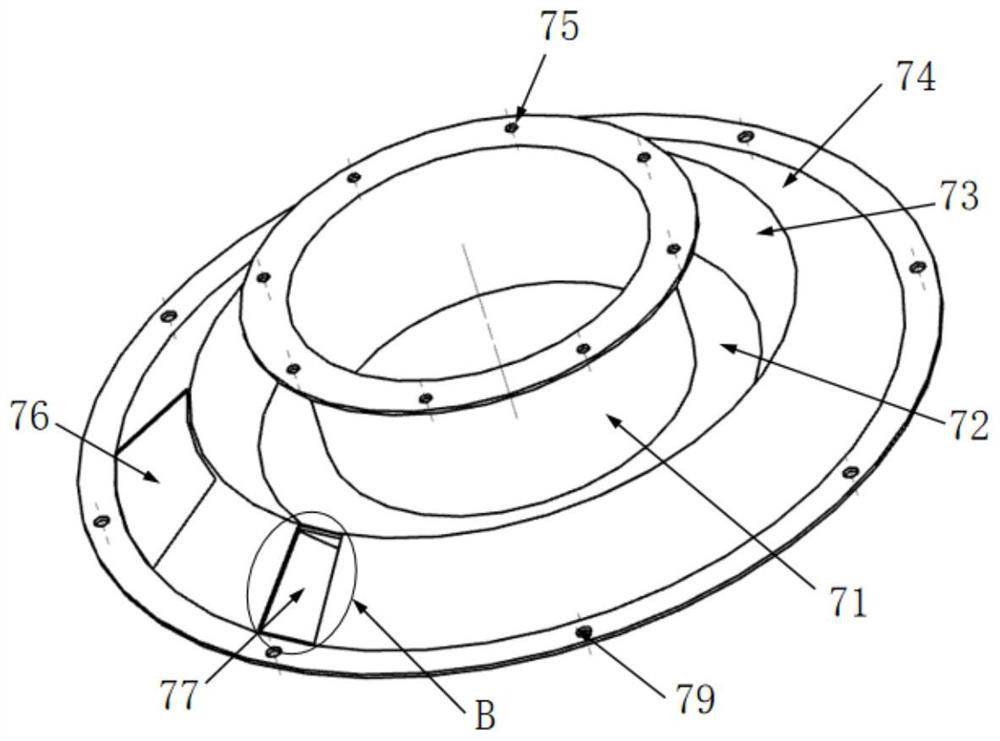

[0027] The windshield system for reducing the wind resistance loss of high-speed spiral bevel gear oil injection lubrication, including the driving wheel shaft, the driving wheel, the driven wheel shaft, the driven wheel, the oil injection pipe on the meshing side, the oil injection pipe on the meshing side, the inlet windshield, Outlet windshield; Spiral bevel gears are installed on the drive shaft and driven shaft, and the spiral bevel gears are equipped with small end side, small end face, tooth face, big end end face and big end side; the driving wheel and the meshing The driven wheels are installed on intersecting shafts, and the angle of intersection of the gear countershafts is 69.77°; oil injection pipes are arranged near the meshing side and the meshing side of the gear pair, and the oil injection pipes on the meshing side are used to lubricate the gears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com