Lubricating grease filling system and filling quantity monitoring method thereof

A filling system and lubricating grease technology, which is applied in the direction of lubricating parts, engine lubrication, lubricating oil control valves, etc., can solve the problems of inaccurate and quantitative filling of equipment, cumbersome replacement of piston parts, etc., and achieve simplified structure and processing The cumbersome process, the effect of improving the convenience of operation and improving the convenience of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in this specific embodiment. Obviously, the implementation described below Examples are only some embodiments of the present invention, but not all embodiments. Based on the embodiments in this patent, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of this patent.

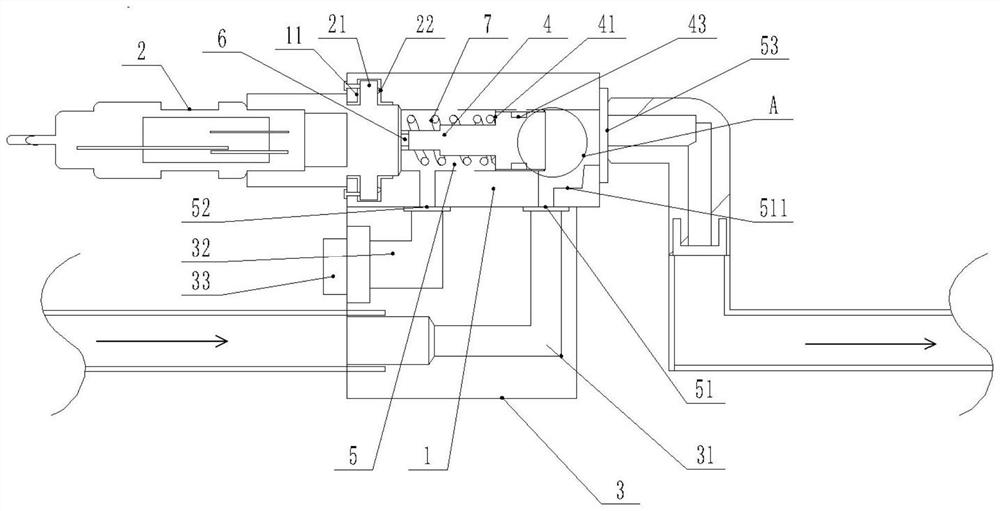

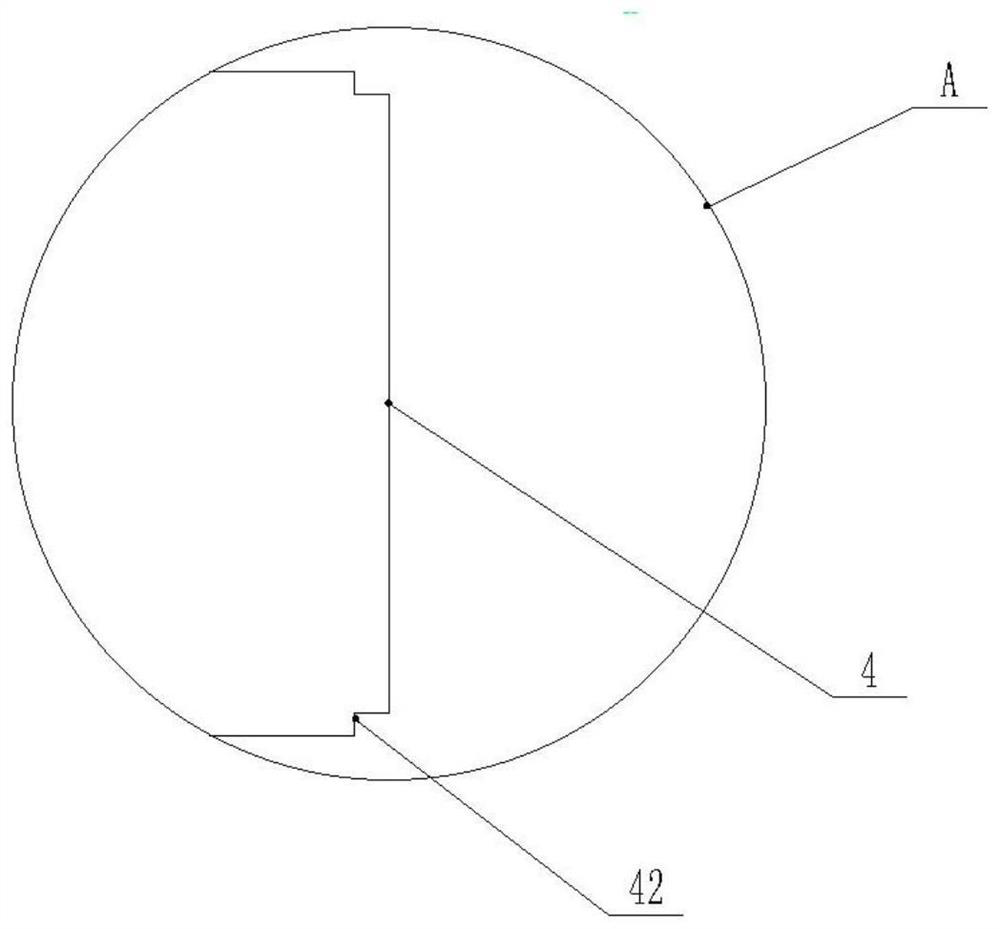

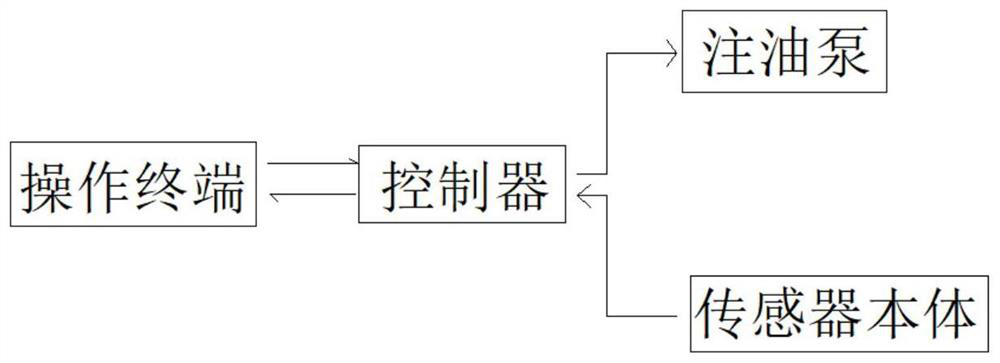

[0032] As shown in the drawings, a grease filling system includes a valve seat 1, a sensor body 2, an oil injection pump, a controller and an operation terminal.

[0033] The valve seat 1 is provided with a valve chamber 5, one end of the valve seat 1 is provided with an oil outlet 53 communicating with the valve chamber 5; the other end is provided with an installation port com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap