Deep hole plate with high practicability

A deep-well plate, practical technology, applied in the direction of test tube holder/clamp, etc., can solve the problems of loose connection between the protection device and the deep-well plate, throwing out of reagent tubes, loss of resources, etc., to increase protection efficiency and facilitate storage , the effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

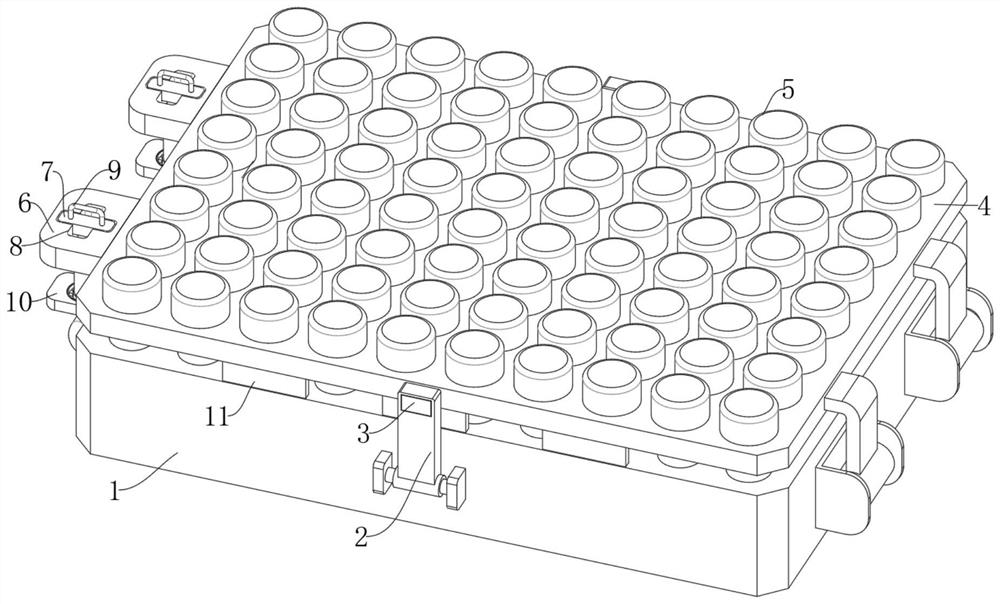

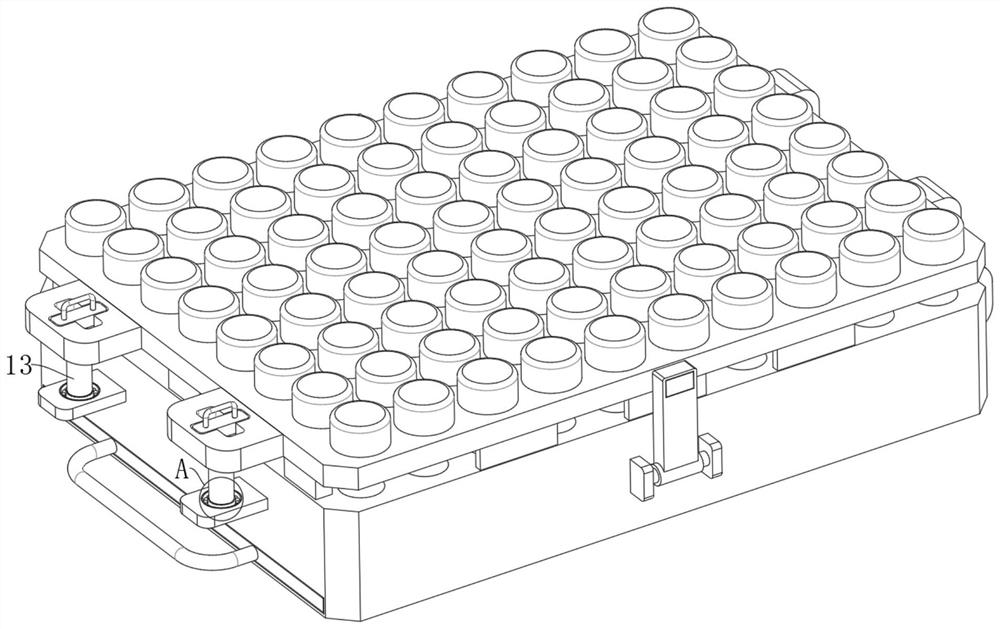

[0029] see Figure 1-5 , the present invention provides the following technical solutions:

[0030] A highly practical deep well plate, including:

[0031] The deep well plate body 1, one end of the deep well plate body 1 is movably hinged with the protective plate 4 through the hinge shaft;

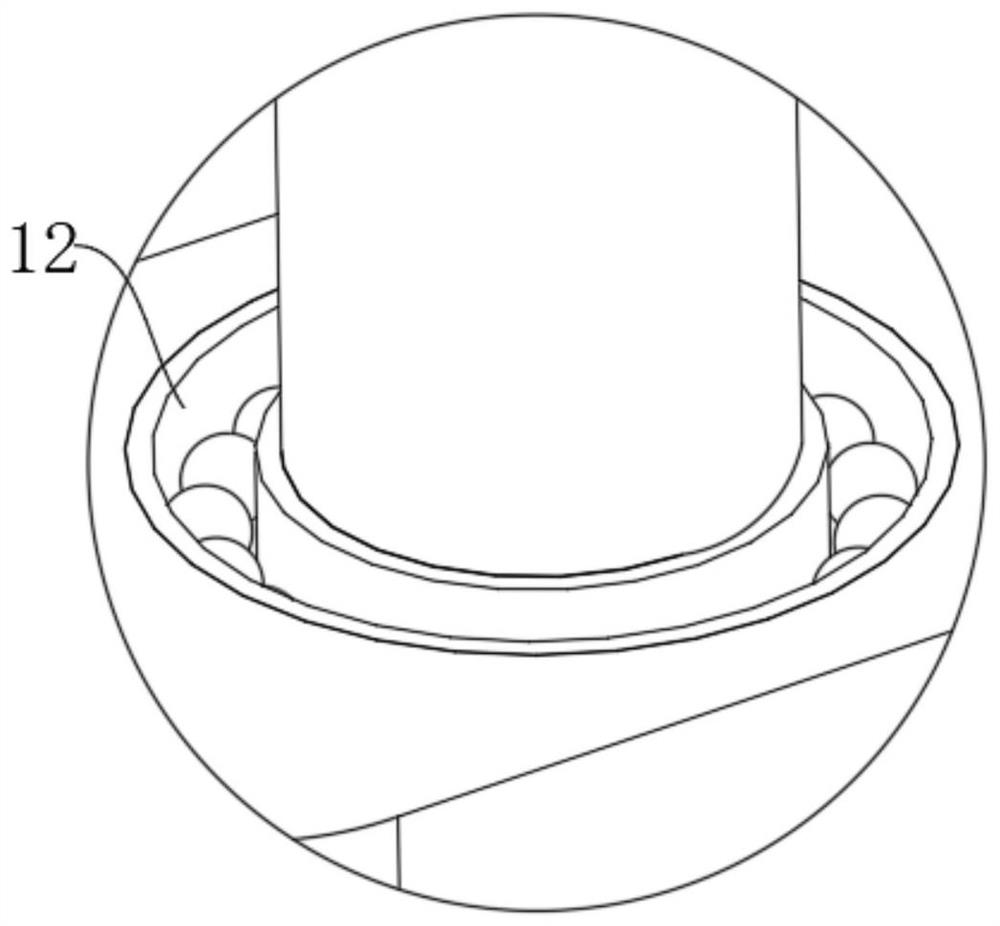

[0032] Two sets of clamping mechanisms, each set of clamping mechanisms are composed of a connecting plate 6, a support block 10, a penetration hole 8, a clamping block 7, a clamping groove and a spring telescopic rod 13, and the support block 10 is fixedly connected to the deep hole plate One end of the body 1, the connection plate 6 is fixedly connected to one end of the protection plate 4, the penetration hole 8 and the snap-in groove are all opened on the upper end of the connection plate 6, and the spring telescopic rod 13 is rotated on the upper end of the support block 10, and the snap-in block 7 is fixedly connected to the upper end of the spring telescopic rod 13, and the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com