Carrier vehicle early warning system and carrier vehicle early warning method

An early warning system and truck technology, applied in transportation and packaging, vehicle parts, lifting devices, etc., can solve the problems of driving safety hazards, failure to judge and prompt driving information, frequent occurrence of overloading, etc., to prolong service life, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

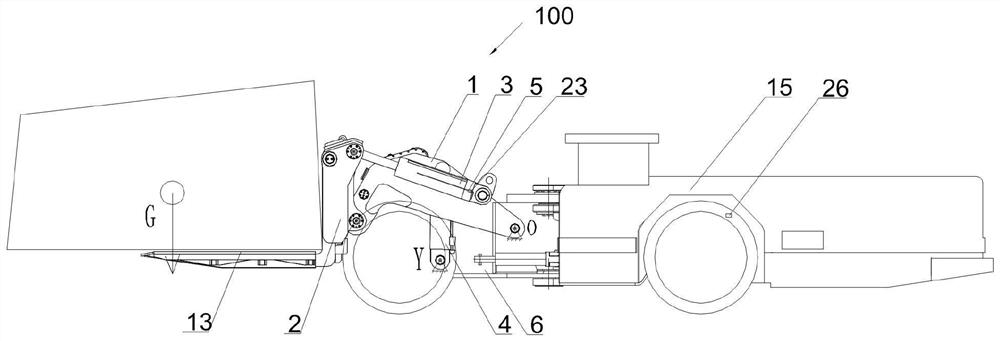

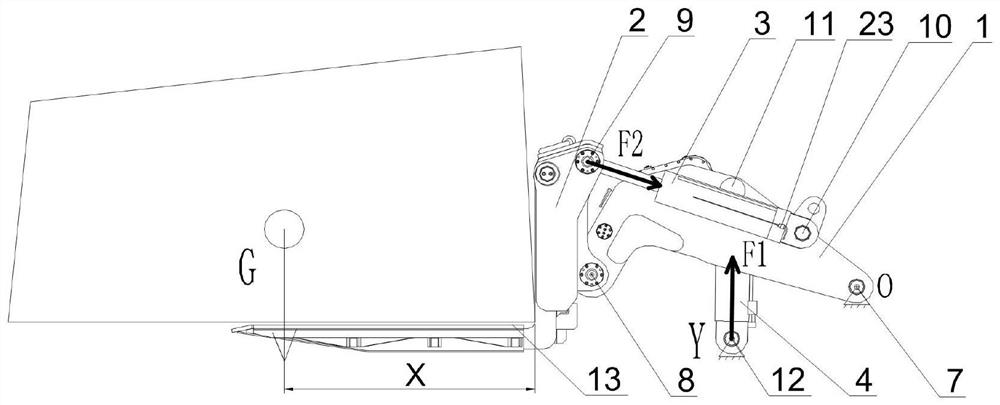

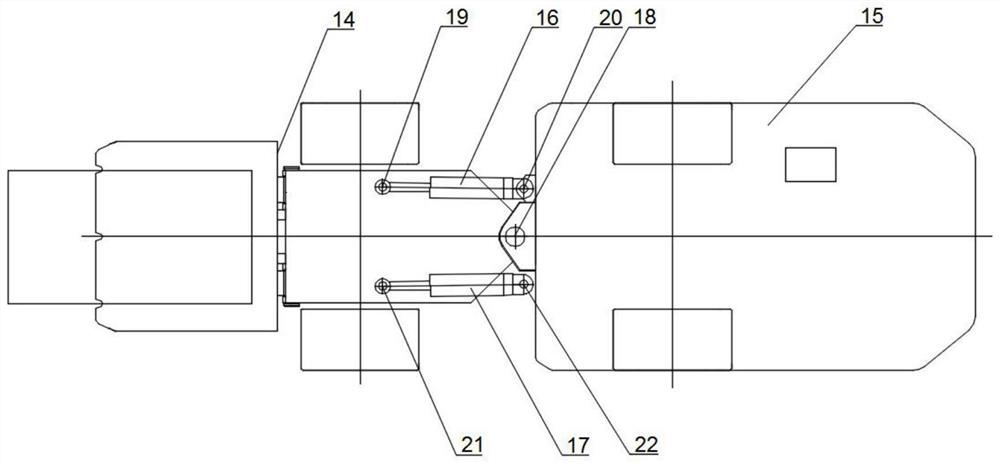

[0102] Such as Figure 1-3 As shown, the present embodiment provides a truck early warning system 100, including a boom 1, a carrying device 2, a first telescopic device 3, a second telescopic device 4 and a safety control device 5, and one end of the boom 1 is used to communicate with the front The car body 6 forms a rotational connection around the first axis 7, the bearing device 2 forms a rotational connection with the other end of the boom 1 around the second axis 8, and the bearing device 2 and one end of the first telescopic device 3 form a rotation connection around the third axis 9. The other end of the first expansion device 3 forms a rotation connection with the boom 1 around the fourth axis 10, the output end of the second expansion device 4 forms a rotation connection with the boom 1 around the fifth axis 11, and the second The other end of the telescopic device 4 is used to form a rotation connection with the front body 6 around the sixth axis 12, the first axis ...

Embodiment 2

[0109] Such as Figure 1-3As shown, Embodiment 2 provides a truck early warning method based on the truck early warning system 100 in Embodiment 1, including:

[0110] Step S1: the safety control device 5 detects the expansion distance of the first expansion device 3, the pressure before and after the expansion of the first expansion device 3, the expansion distance of the second expansion device 4, and the pressure before and after the expansion of the second expansion device 4;

[0111] Step S2: The safety control device 5 obtains the value of the cargo through the detected expansion and contraction distance of the first expansion device 3, the pressure before and after the expansion of the first expansion device 3, the expansion and contraction distance of the second expansion device 4, and the pressure before and after the expansion of the second expansion device 4. Weight and overhang distance X.

[0112] Step S1 includes: respectively detecting the telescopic distances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com