Steel wire rope traction type bar screen machine

A traction type, wire rope technology, applied in the field of wire rope traction type grille decontamination machine, can solve the problems of long interval between sewage discharge, low sewage discharge efficiency, insufficient sewage discharge speed, etc., and achieves stable use, high reliability and reasonable structure. , mutual hindering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

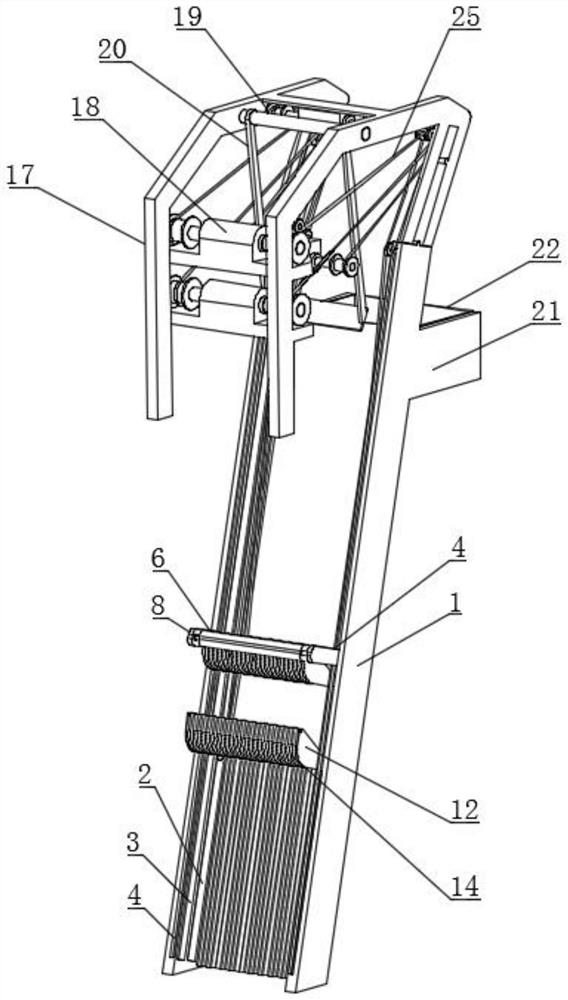

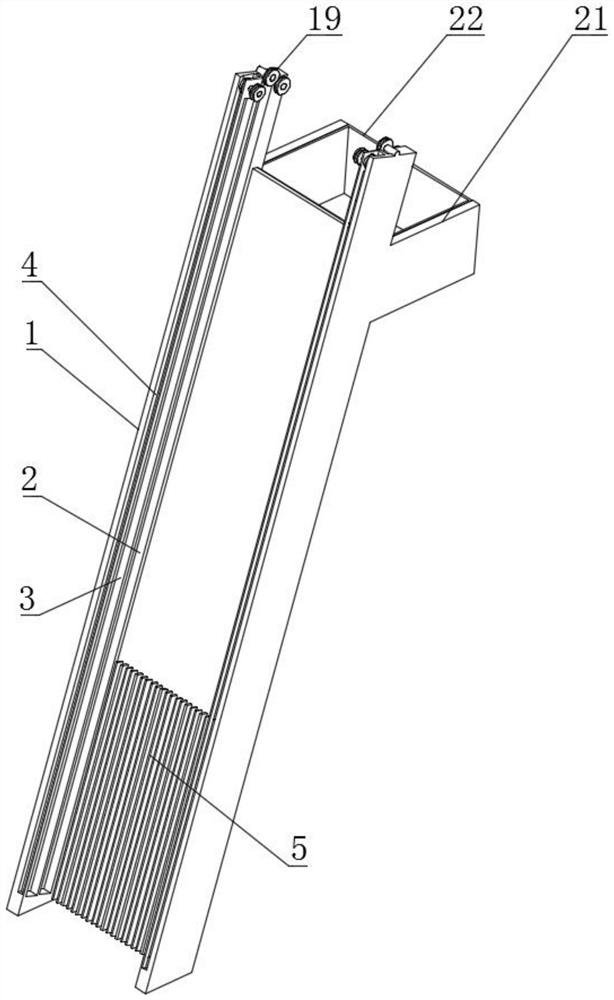

[0031] see Figure 1-6 , a wire rope traction type grille decontamination machine, comprising a lifting bracket 1, a filter grid 5 is fixedly installed on the inner side of the bottom end of the lifting bracket 1, inner slideways 2 are symmetrically provided on both sides of the inner surface of the lifting bracket 1, and inner slideway 2 There is a first decontamination rake mechanism for the lifting of dirt. The upper side of the inner slideway 2 is provided with an outer slideway 3. The top of the outer slideway 3 runs through a limited slideway 4. The outer slideway 3 and the limit A second decontamination rake mechanism for lifting dirt is movably connected between the slideways 4, a drive mechanism for providing driving capability is fixedly installed on the top of the lifting bracket 1, and a storage mechanism for collecting dirt is provided on the side of the top of the lifting bracket 1.

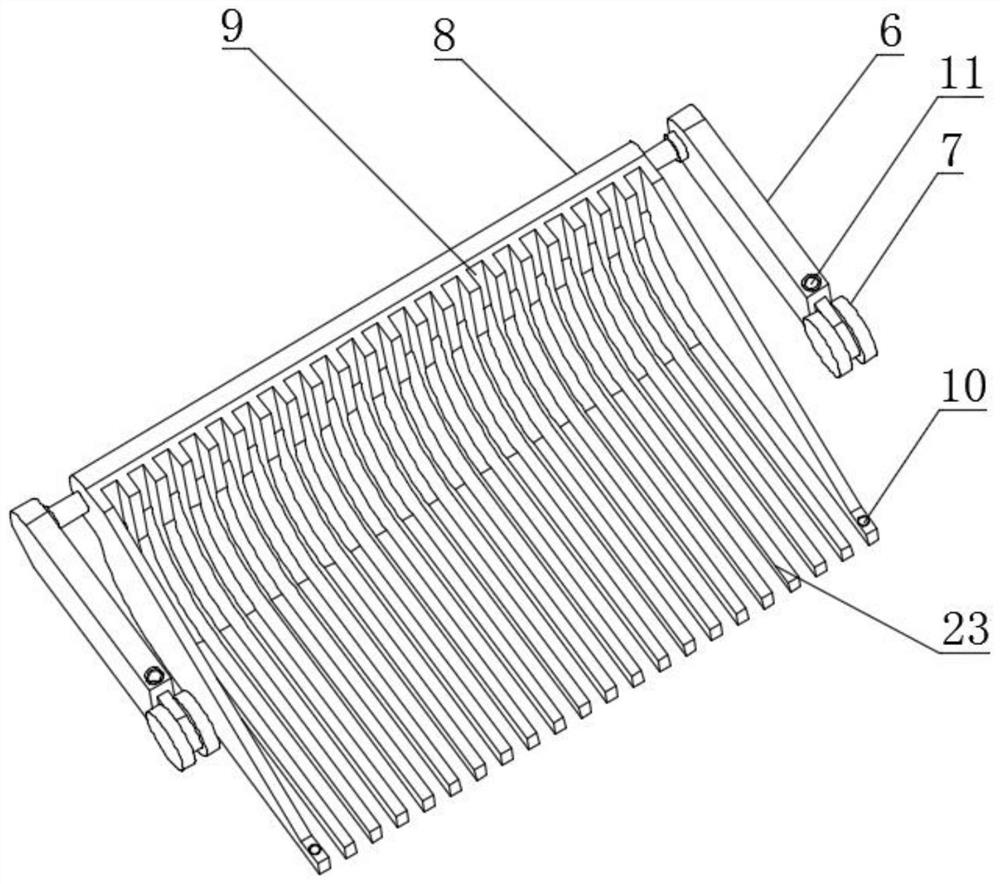

[0032] refer to figure 1 and Figure 4 , the first decontamination rake mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com